0102030405

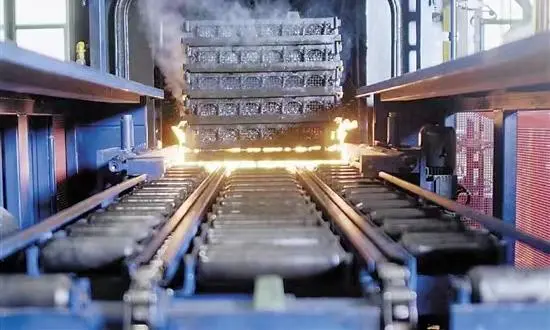

High speed steel manufacturing process

2024-06-05

The heat treatment process of high-speed steel is relatively complex and must go through a series of processes such as quenching and tempering. Quenching is generally performed in two stages due to its poor thermal conductivity. First preheat at 800~850℃ (to...

view detail

Alloy steel element combination

2024-06-05

The main alloying elements of alloy steel are silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminum, copper, boron, rare earths, etc.1. Carbon (C): As the carbon content in steel increases, the yie...

view detail

Application of angle steel

2024-06-05

Angle steel can be used to form various stress-bearing components according to different structures, and can also be used as connectors between components. It is widely used in various building structures and engineering structures, such as house beams, bridge...

view detail

Structural features of wear-resistant steel plates

2024-06-05

Wear-resistant steel plate consists of two parts: low carbon steel plate and alloy wear-resistant layer. The alloy wear-resistant layer is generally 1/3~1/2 of the total thickness. During operation, the matrix provides comprehensive properties such as strength...

view detail

How to maintain color steel coils and extend their service life

2024-06-04

Color steel coils are a common building material with the advantages of fire protection, anti-corrosion, and weather resistance. Therefore, they are widely used in roofs and walls of industrial plants, warehouses, commercial buildings and other buildings. In o...

view detail

How to choose the best carbon steel grade

2024-06-04

Carbon Steel is a metal used in many different industries, as it is affordable and has a wide range of properties that can be used in a variety of mechanical applications. This type of steel is 0.5 percent to 2.0 percent carbon with iron and trace levels of ot...

view detail

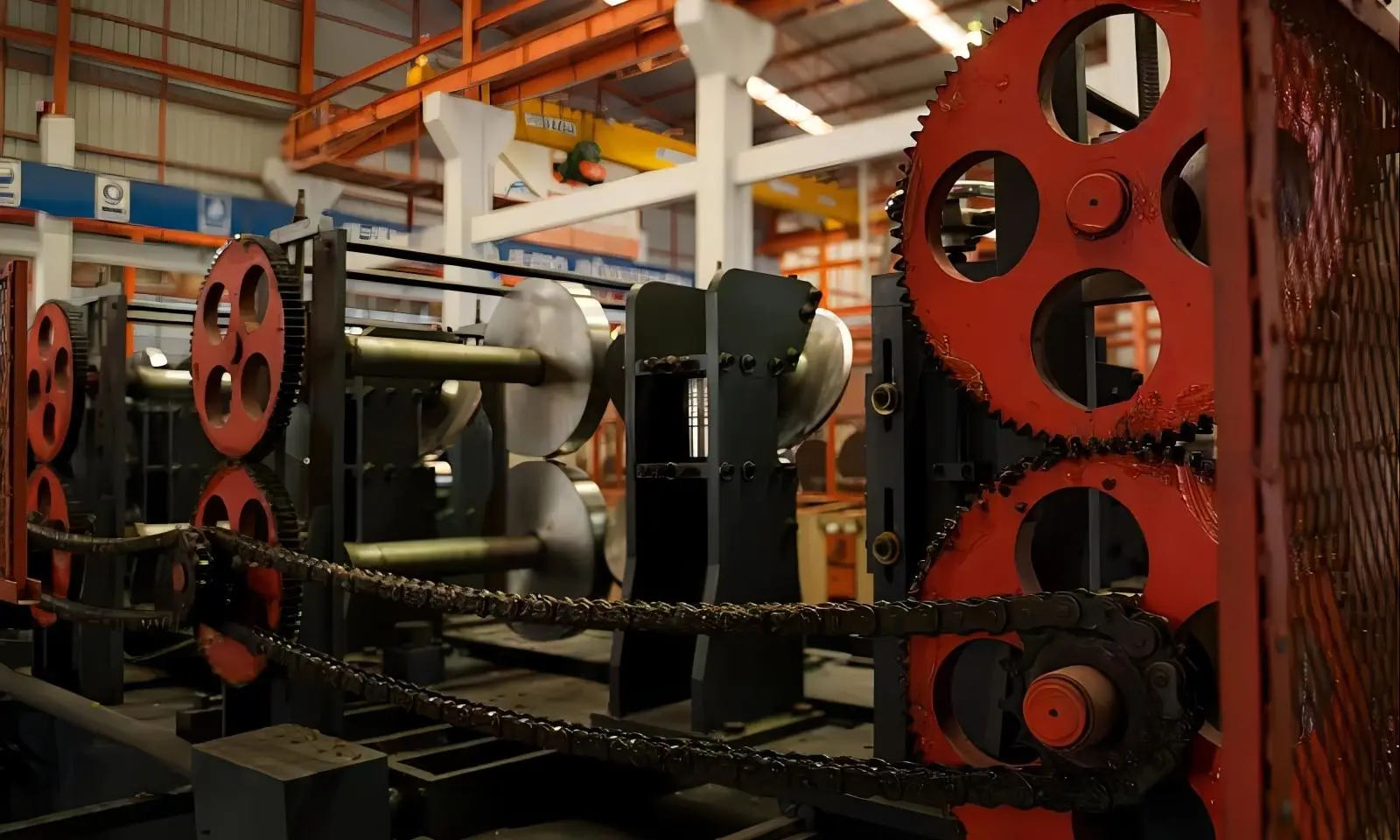

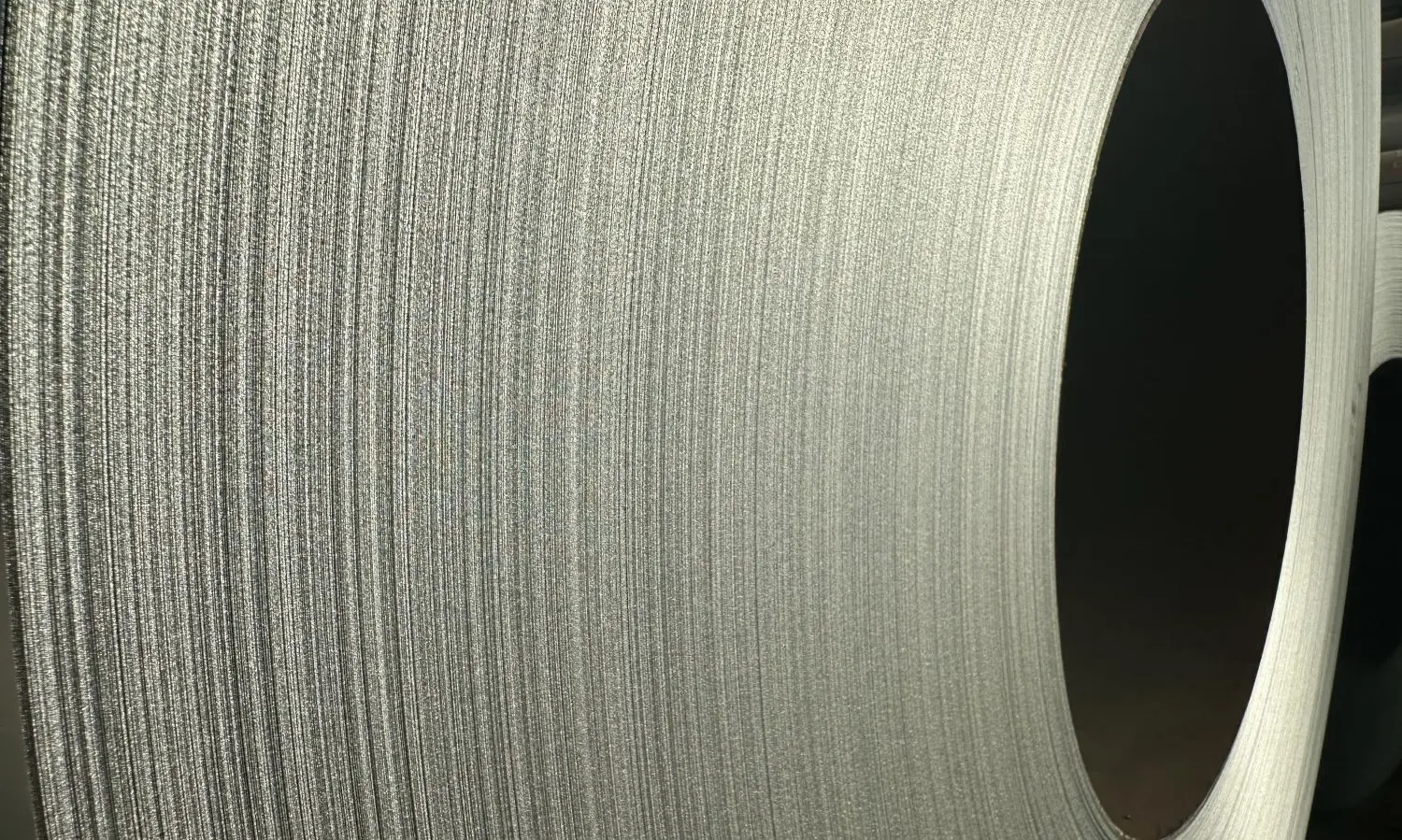

What is cold rolled coil

2024-06-04

Cold rolled coils are commonly known as cold plates. It is made of ordinary carbon hot-rolled steel strip and further cold-rolled into a steel plate with a thickness of less than 4mm. Since it is rolled at room temperature, no iron oxide is produced. Compared ...

view detail

The steel with the most stringent production requirements -bearing steel

2024-06-04

Bearing steel is the steel used to make balls, rollers and bearing rings. Bearing steel has high and uniform hardness and wear resistance, as well as high elastic limit. The requirements for the uniformity of the chemical composition of bearing steel, the cont...

view detail

Quality control of seamless steel pipes

2024-06-04

In order to ensure the quality of seamless steel pipes, Shandong Tezhong Materials Co., Ltd. has always insisted on controlling the following aspects: a. Raw materials: Use high-quality steel billets to ensure that there are no defects, bubbles, or cracks on ...

view detail

Choose cold dip galvanizing or hot dip galvanizing

2024-06-04

Cold galvanizing and hot-dip galvanizing each have their own advantages and disadvantages, so your choice is not only related to the anti-corrosion effect of metal materials, but also related to production costs and product quality, which needs to be decided b...

view detail