The following are the 6 most important steps in the Tezhong Materials loading process

2024-06-05

Step 1: Preparation

Before you start installing cabinets, we need to do some preparations. This includes confirming order details, checking the quality and quantity of rolls, preparing packaging materials required for cabinet loading, etc.

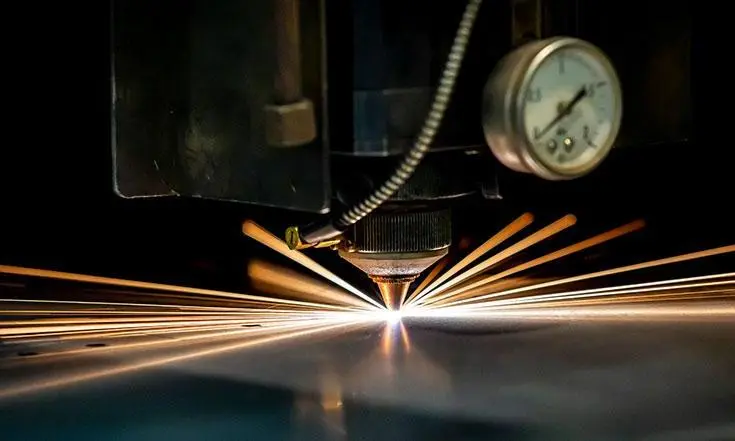

Step 2: Packaging and Labeling

Packaging the roll stock is a critical step in ensuring its safety during transportation. Typically, roll stock is wrapped in protective paper or plastic film to prevent scratches and corrosion. In addition, each roll should also be marked with relevant information, such as batch number, specifications, weight, etc.

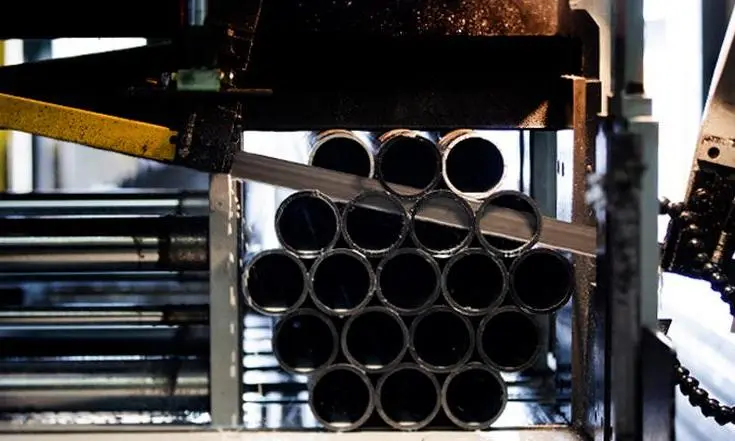

Step 3: Stack and Bundle

When stacking packaged coils in containers, attention should be paid to the stability and safety of the stack. Wooden or metal pallets are usually used and tied with steel straps or ropes to ensure that the coils do not slip or get damaged during transportation.

Step 4: Container Loading

Once the roll stock is ready, it can be loaded into the container. During container loading, attention needs to be paid to even distribution of weight and rational use of space. Using a forklift or other handling equipment, move the coils from the loading area to the container, arranging and stacking them as tightly as possible.

Step 5: Secure securely

Once the rolls are loaded into the container, it is important to ensure they are secured in place to prevent them from moving or rolling during transport. Use a tool such as strapping, rope, or wood to secure the roll to the container wall or floor.

Step 6: Container Close Seal

Once the container is loaded, the container door is closed and sealed to ensure that the goods are not affected by the outside environment during transportation. Sealing may be performed using seals or other closure devices.