Width Carbon Steel Coil is a versatile material in various industries. It is known for its strength and durability. These coils are made from high-quality carbon steel. They come in different widths, catering to diverse applications.

In construction, Width Carbon Steel Coil is often used for structural components. It provides essential support and stability. Additionally, it finds use in manufacturing, especially in producing machinery and tools. The flexibility of the coil allows for easy handling and processing.

However, there are challenges. Not all Width Carbon Steel Coils are created equal. Companies must choose the right specifications for their needs. Inadequate selection can lead to structural failures. This reflects the importance of careful consideration when using this material.

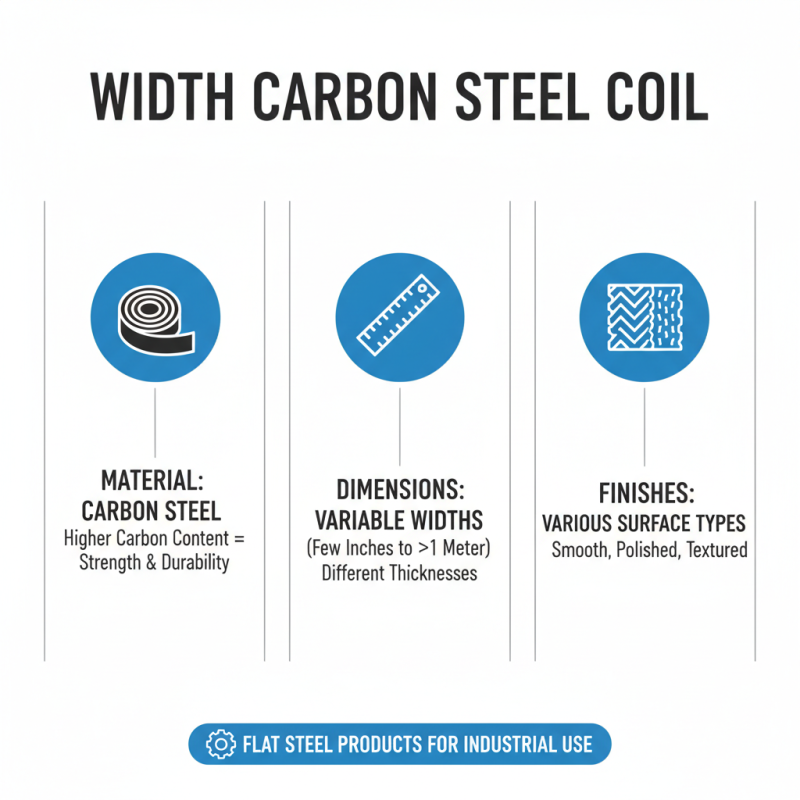

Width Carbon Steel Coil refers to flat steel products produced in various widths. These coils are made from carbon steel, which has a higher carbon content than other steel types. This gives them strength and durability. The typical width ranges from a few inches to over a meter. They are available in different thicknesses and surface finishes.

One key characteristic of Width Carbon Steel Coils is their versatility. They are easy to cut, shape, and weld. Industries often use them in construction and manufacturing. From automotive parts to building structures, these coils are essential. They can be rolled or processed into various forms. This adaptability makes them popular.

Tips: When working with Width Carbon Steel Coils, ensure you have the right tools. Accidental cuts and welds can happen if not careful. Pay attention to thickness and width specifications. It’s crucial to consult with manufacturers for precise measurements. Always think about the end application. Sometimes mistakes in sizing may lead to material waste.

The manufacturing process of width carbon steel coil involves several critical steps. First, raw steel is produced. Iron ore is transformed into molten iron through a series of processes. This molten iron is then converted into steel by removing impurities. The steel is further processed into large slabs or billets.

Next, these slabs are heated and passed through a series of rollers. This rolling process reduces the thickness and increases the length and width of the steel. The temperature is crucial. Too hot, and it can warp; too cold, and it won’t shape properly. Consistent monitoring is needed to ensure quality. This stage requires a skilled workforce.

After rolling, the steel coil undergoes several finishing processes. These include annealing and pickling. Annealing helps to relieve internal stresses. Pickling cleans the coil's surface. The final product is checked for quality and thickness. However, imperfections can occur. These often require additional steps for correction. Each coil needs careful inspection. Otherwise, minor flaws can lead to significant issues in production.

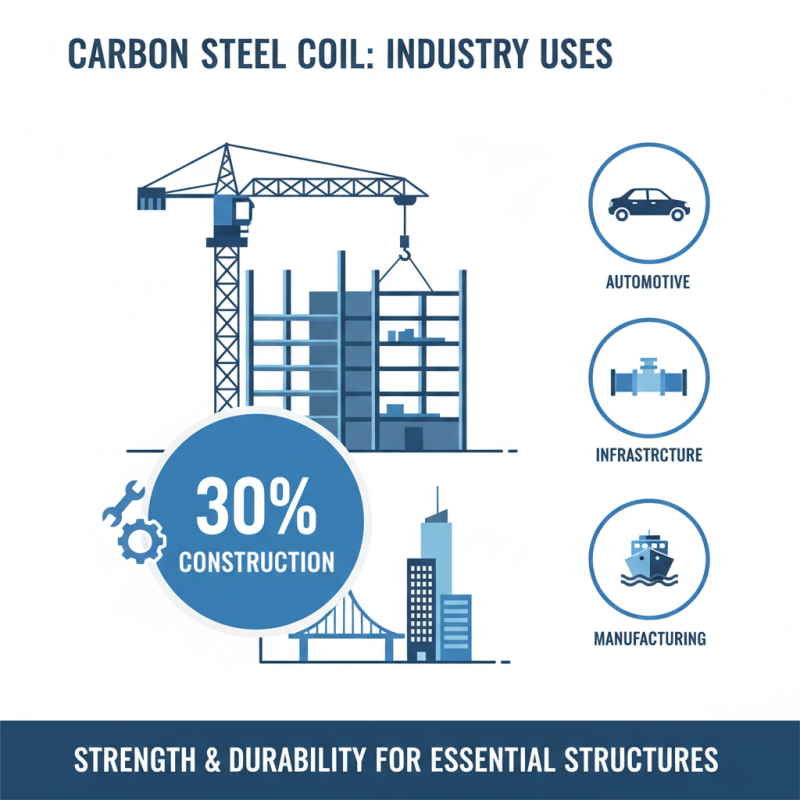

Width carbon steel coil is widely used across various industries. One of its primary applications is in the construction sector. According to industry reports, around 30% of carbon steel produced is utilized in building structures. This material offers strength and durability, making it ideal for beams, rods, and other structural components. These elements are essential in ensuring safety and longevity in construction projects.

Manufacturing is another significant area where width carbon steel coil finds practical use. Data suggests that this steel accounts for about 40% of the materials used in manufacturing machinery and equipment. It’s particularly useful for creating automotive parts and appliances. Its ability to be easily shaped and welded allows for high efficiency in production processes. However, not all applications run smoothly. Some industries face challenges with corrosion and wear. This necessitates careful consideration and sometimes additional treatments for optimal performance.

In the energy sector, width carbon steel coils are crucial for pipelines and storage tanks. Reports indicate that nearly 20% of these coils are used for transporting fluids. The specific grades of carbon steel can significantly impact their lifecycle and reliability. This constant need for evolution and improvement in application methods reveals ongoing industry challenges. Continuous updates to materials technology are vital to address these concerns effectively.

Width carbon steel coil is becoming increasingly popular across various industries. This material offers significant advantages over alternatives like aluminum or stainless steel. For instance, width carbon steel coils typically exhibit higher strength and durability. According to a recent industry report by Grand View Research, the global demand for carbon steel coils is expected to grow at a CAGR of 4.5% from 2023 to 2030. This trend indicates a strong preference for carbon steel in construction and manufacturing.

One of the key benefits of width carbon steel coil is its cost-effectiveness. It tends to be less expensive than other materials, which can lead to lower overall production costs. A study by the American Iron and Steel Institute shows that using carbon steel can reduce material costs by up to 20% in large projects. Furthermore, carbon steel coils are versatile. They can be easily cut, shaped, and welded, making them suitable for various applications. Yet, the susceptibility to rust and corrosion remains a concern, requiring proper maintenance.

Moreover, the energy efficiency of carbon steel production is noteworthy. Producing carbon steel typically requires less energy compared to stainless steel. However, it is not without its issues. The environmental impact of mining and processing steel cannot be ignored. As industries seek sustainable solutions, the development of eco-friendly practices in carbon steel production is vital. This is a crucial aspect that needs attention and improvement moving forward.

Width carbon steel coils are vital in various industries, from construction to manufacturing. Their quality is influenced by several factors. Understanding these factors can help businesses make better choices.

One significant factor is the raw material used in production. The purity and composition of the steel affect its strength and durability. If impurities are present, the coil may have weak points. This could lead to failures in critical applications. The manufacturing process also plays a crucial role. Inaccurate heating or cooling can cause defects. These defects might remain hidden until later stages of production.

Another element is the thickness and width consistency. Variations can affect the coil's performance in applications like automotive or structural parts. If the measurements are off, compatibility issues can arise. Furthermore, surface finish is essential. A poor finish can lead to corrosion, which compromises functionality. Constant quality checks are necessary, but imperfections can creep in. Awareness of these factors allows for better preventive measures and improved product outcomes.