When embarking on your next project, consider the versatile Carbon Steel Coil Stip. This material offers strength and flexibility for various applications. Whether you're crafting decorative elements or structural components, its adaptability is undeniable.

Using Carbon Steel Coil Stip requires careful planning. Start by assessing your project's specific needs. This material can be easily cut and shaped, allowing for customization. However, improper handling might lead to mistakes. Be mindful of the dimensions and weight during your design phase.

Each project has its unique challenges. You may encounter difficulties in bending or welding this metal. Reflecting on your process can lead to improvements. The more you experiment with Carbon Steel Coil Stip, the more confident you'll become. It's a journey of learning, refining your skills with each creation.

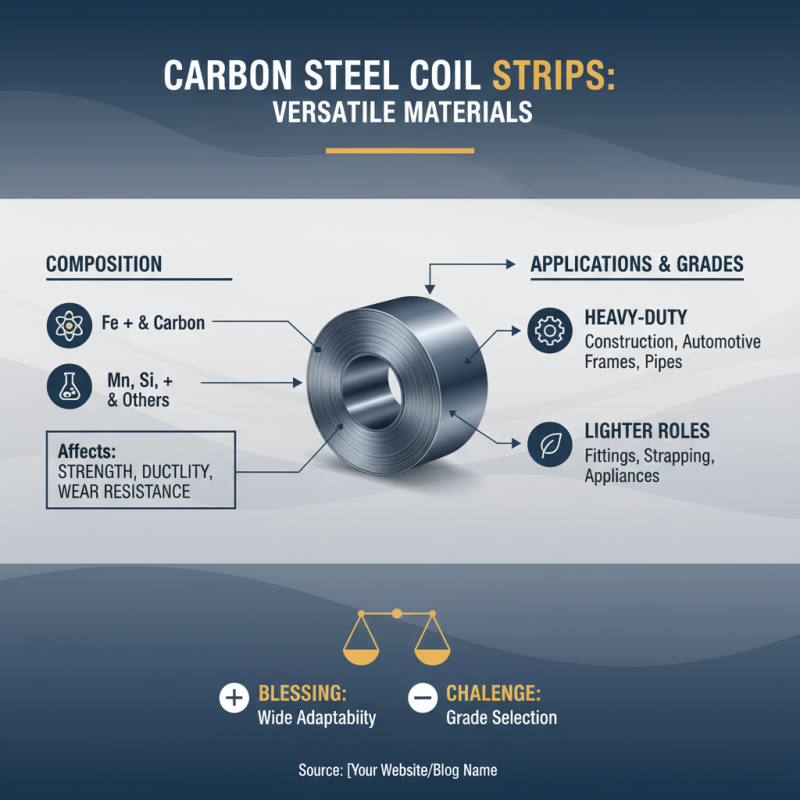

Carbon steel coil strips are versatile materials used in many projects. They contain iron and carbon, with other elements like manganese and silicon. The specific composition affects strength, ductility, and resistance to wear. Different grades serve various applications. Some strips are suitable for heavy-duty tasks, while others excel in lighter roles. This variability can be both a blessing and a challenge.

Understanding properties is crucial. Carbon content impacts hardness and brittleness. Higher carbon levels increase strength but may reduce flexibility. This creates a dilemma when choosing the right strip for your needs. Are you prioritizing durability or ease of manipulation? Think about your project requirements carefully.

Carbon steel is also prone to corrosion. Proper coatings can help, yet maintenance is key. Over time, wear may affect performance. Be prepared to reflect on your choices. The right strip can enhance your project, but the wrong one can lead to complications. Adaptability in your approach can make all the difference.

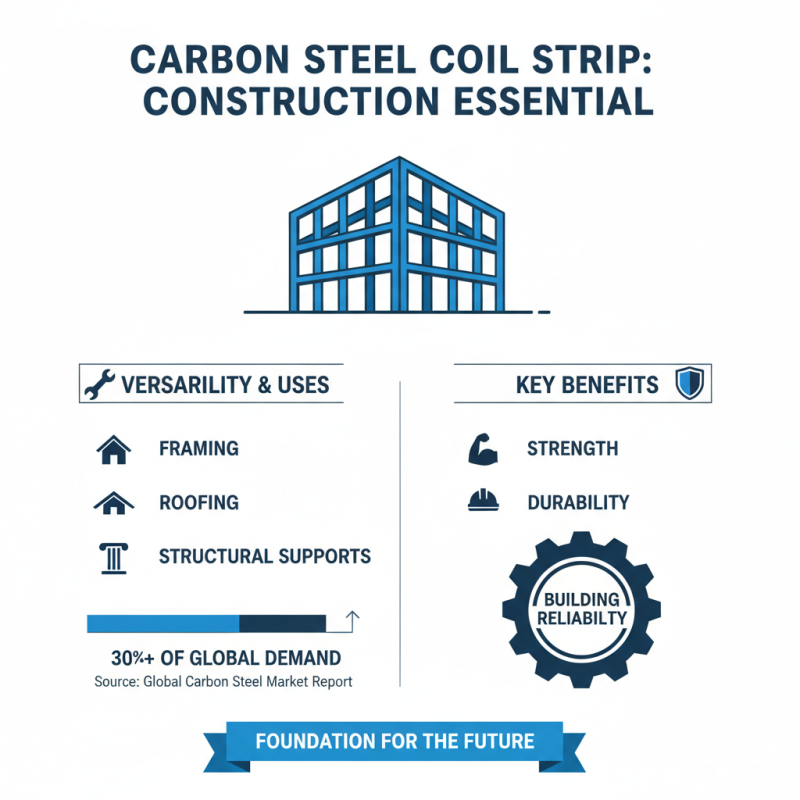

Carbon steel coil strip is versatile and widely used across different industries. In construction, it serves as a reliable component for framing, roofing, and structural supports. According to the Global Carbon Steel Market Report, the construction sector accounts for over 30% of carbon steel demand, highlighting its importance. This material is essential for providing strength and durability in building projects.

Automotive manufacturing also heavily relies on carbon steel coil strip. It is used in producing body panels, chassis, and other components. The automotive industry is projected to use approximately 50 million tons of carbon steel annually, as per the Automotive Steel Alliance report. This usage underscores the need for quality materials that can withstand daily wear and tear. However, challenges remain in balancing production costs and quality.

In the appliance sector, carbon steel coil strip plays a critical role in creating durable items. It is commonly found in refrigerators, washers, and ovens. This sector is driven by consumer demand for energy-efficient and long-lasting appliances. Despite its popularity, manufacturers face scrutiny regarding the environmental impact of steel production. The industry must innovate to mitigate these concerns while meeting customer expectations.

When selecting carbon steel coil strips, thickness and width matter significantly. A report from the

American Institute of Steel Construction suggests that

thicknesses can range from 0.020 inches to over 0.250 inches. The chosen thickness can

influence strength, durability, and flexibility. For instance, a thinner strip often offers better

flexibility for applications requiring intricate bends. Yet, too thin may compromise strength in load-bearing contexts.

Width plays a crucial role as well. Common widths range from 1 inch to 40 inches.

Choosing the right width is essential for the project’s requirements. A narrower coil strip is preferable for

tight spaces, but it may require more cuts and joints. Data from industry surveys show that wider strips reduce

overall seam counts, which can enhance structural integrity but could also lead to material waste.

One must also reflect on project needs. A heavier coil may seem beneficial but can increase handling

difficulties. Each project brings unique challenges that must be considered. Balancing thickness and width with

application demands is often complex but essential for a successful outcome.

When working with carbon steel coil strips, proper fabrication and handling are essential. Carbon steel is versatile and strong, making it a choice for various projects. The thickness and width can vary, adding flexibility to your design. Before beginning your work, always wear appropriate safety gear. Gloves protect your hands from sharp edges. Safety goggles shield your eyes from metal dust.

During fabrication, one might encounter challenges. Ensure that the working area is clean and well-lit. Any clutter can lead to accidents or errors. Use proper tools for cutting and bending. A dull blade can mar the finish or create inaccuracies. If a cut does not go as planned, take the time to assess and adjust before proceeding.

Tips: Overheating the steel during bending can alter its properties. Cool it down with water or let it air-cool to maintain integrity. Always double-check your measurements. A small mistake can lead to larger issues down the line. Reflect on your techniques and learn from any mishaps. Improvement comes with practice and attention to detail.

| Dimension (inches) | Weight (lbs/coil) | Thickness (gauge) | Coil Width (inches) | Applications |

|---|---|---|---|---|

| 24 x 36 | 2000 | 18 | 24 | Automotive Parts |

| 36 x 48 | 2500 | 16 | 36 | Construction |

| 48 x 60 | 3000 | 14 | 48 | Appliances |

| 60 x 72 | 3500 | 12 | 60 | Machinery Parts |

| 72 x 84 | 4000 | 10 | 72 | Industrial Applications |

When working with carbon steel coil strips, safety is paramount. The material can be heavy and sharp, posing risks. A recent industry report noted that improper handling resulted in over 15% of injuries in fabrication environments. Always wear appropriate safety gear, including gloves and goggles. Ensure the work area is clean and that tools are in good condition to reduce accidents.

Maintenance is another critical aspect. Carbon steel is prone to rust. A study revealed that nearly 20% of projects failed due to inadequate corrosion protection. Regular inspections are essential. Clean the strips regularly and apply a protective coating when necessary. Pay attention to the storage conditions as well. Properly stored materials can last longer and perform better. Documentation of maintenance practices can help in improving future projects.

Despite these precautions, mistakes happen. It’s important to assess practices periodically. Reflect on what went wrong. Was the equipment adequate? Were safety measures strictly followed? Gathering data from each project can lead to improvement. Continuous learning is vital for successful long-term use of carbon steel coil strips.