In the evolving landscape of the manufacturing and construction industries, **Carbon Steel Hot Rolled Coil** plays a pivotal role due to its exceptional properties and versatility. According to a recent industry report published by the Global Steel Association, the demand for hot rolled carbon steel is projected to grow at a compound annual growth rate (CAGR) of 3.5% between 2023 and 2028. This growth is propelled by its fundamental use in various applications, ranging from structural components to automotive parts.

Industry expert Dr. Emily Carter, a noted metallurgical engineer, underscores the significance of understanding the uses and benefits of Carbon Steel Hot Rolled Coil in her recent analysis, stating, "The adaptability and strength of hot rolled coils make them indispensable in today’s industrial applications.” Her insights highlight how these materials contribute to enhanced structural integrity and cost-effectiveness, making them a preferred choice for engineers and manufacturers alike.

As businesses seek sustainable and efficient solutions, embracing the advantages of **Carbon Steel Hot Rolled Coil** can provide a competitive edge. This introduction aims to guide stakeholders in recognizing the vital role of this material, helping them make informed decisions in their respective sectors.

Carbon steel hot rolled coil is a vital material in various industries, renowned for its versatility and strength. This type of steel is produced by rolling heated slabs of carbon steel at high temperatures, resulting in a material that is not only malleable but also exceptionally durable. The hot rolling process helps eliminate internal stresses, making it easier to work with during fabrication processes. As a result, carbon steel hot rolled coils are widely used in manufacturing applications, construction, and automotive components, among others.

When considering the uses and benefits of carbon steel hot rolled coils, it's essential to keep a few tips in mind. First, the material's high strength-to-weight ratio makes it an excellent choice for structures requiring robust materials without excessive weight. Second, due to its cost-effectiveness, hot rolled coils are often preferred in large-scale projects where budget constraints are a consideration. Lastly, the excellent weldability of this steel type means it can be easily combined with other materials, enhancing its application in composite structures. Understanding these aspects can help industries make informed decisions about their material needs.

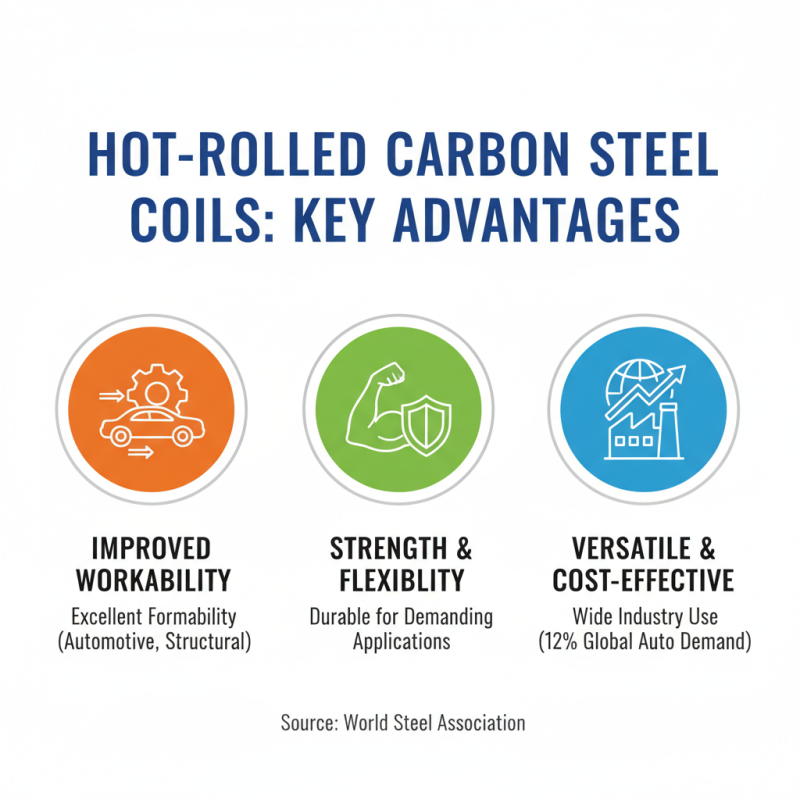

Hot rolled carbon steel coils are widely used across various industries due to their versatility and strength. One of the primary applications of these coils is in the manufacturing of automotive components. According to the World Steel Association, approximately 12% of global steel production is utilized in the automotive sector, highlighting the importance of carbon steel in producing everything from body panels to structural components. Additionally, hot rolled steel is essential for producing heavy machinery and equipment, as its durability can withstand the rigors of operation in harsh environments.

In construction, hot rolled carbon steel coils play a crucial role in structural framework and reinforcements. The American Institute of Steel Construction reports that hot rolled steel is favored for its reduced fabrication costs and enhanced design flexibility. Furthermore, the coils are integral to the production of pipes and tubes, which are vital in energy and infrastructure projects, offering both strength and resistance to high-pressure conditions.

Tip: When selecting hot rolled carbon steel for projects, consider the thickness and finish required to meet specific application needs. It may also be beneficial to consult with industry specialists to understand the distinct grades and properties of carbon steel available, ensuring that your choice aligns with functional and environmental considerations.

Tip: Regular inspections and maintenance of carbon steel components can enhance longevity, particularly in industrial applications where exposure to corrosive elements is prevalent. Investing in protective coatings or treatments can significantly improve their lifespan and performance.

Hot rolled carbon steel coils offer several key advantages in manufacturing, making them a preferred choice across various industries. One significant benefit is their improved workability. The hot rolling process allows manufacturers to produce steel sheets with excellent formability, which is critical for applications such as automotive components and structural parts. According to the World Steel Association, the automotive sector accounts for approximately 12% of global steel demand, heavily relying on hot rolled steel for its blend of strength and flexibility.

Another advantage is the cost-effectiveness of hot rolled carbon steel coils. The production process generally requires less energy compared to cold rolling, allowing manufacturers to benefit from lower operational costs. A report by the American Iron and Steel Institute indicates that the use of hot rolled steel can reduce manufacturing expenses by up to 20% in certain applications due to its simplified processing requirements. This financial efficiency, coupled with the material's favorable mechanical properties, makes hot rolled carbon steel an ideal choice for large-scale manufacturing projects.

Additionally, hot rolled coils provide excellent surface qualities, which are beneficial for further processing. While some applications may require additional finishing, the initial surface state of hot rolled products ensures good adhesion for paints and coatings, enhancing product durability. Industry research shows that nearly 60% of manufacturers use hot rolled carbon steel in their production lines, showcasing its importance in the supply chain and its versatility across various applications, from machinery to construction.

Hot rolled carbon steel coils are manufactured in accordance with various industry standards and specifications that govern their quality and performance. These standards help ensure that the steel meets specific mechanical and chemical properties, making it suitable for a wide range of applications. Common specifications, such as those from ASTM (American Society for Testing and Materials) or JIS (Japanese Industrial Standards), outline the required tensile strength, yield strength, and elongation levels, which are critical for assessing the material's suitability for structural applications.

Additionally, hot rolled carbon steel coils must adhere to standards that address surface quality and finish. These criteria are crucial for applications where aesthetic appeal and surface integrity are paramount. Specifications detail the acceptable levels of surface imperfections, such as scale and rust, which can affect the overall performance of the finished products. By following these industry standards, manufacturers ensure that their hot rolled carbon steel coils provide reliable performance and can withstand the stresses of various industrial applications, including construction, automotive, and manufacturing sectors.

The market for carbon steel hot rolled coils has been experiencing significant shifts, driven by various factors including advances in manufacturing techniques and shifts in consumer demand. According to a report by Industry Research, the global carbon steel hot rolled coil market was valued at approximately $250 billion in 2022 and is projected to reach $310 billion by 2030, reflecting a compound annual growth rate (CAGR) of about 3.5%. This growth is largely influenced by increasing applications in industries like construction, automotive, and manufacturing, where the durability and cost-effectiveness of hot rolled coils are highly valued.

Future projections suggest that the carbon steel hot rolled coil market will continue to evolve with the integration of sustainable practices and technologies. A report from the Steel Market Development Institute indicates that environmentally friendly production methods are becoming paramount, impacting procurement decisions across sectors. As industries transition towards greener solutions, the demand for high-quality, less carbon-intensive products is expected to rise, prompting manufacturers to invest in innovation. Furthermore, advancements in smart manufacturing are anticipated to enhance production efficiency, reducing waste and costs—key factors that will shape the competitive landscape of carbon steel hot rolled coils in the coming years.

| Application | Benefits | Market Trends | Future Projections |

|---|---|---|---|

| Construction | High strength, cost-efficiency, and durability | Increasing demand due to infrastructure development | Projected growth of 5% annually through 2030 |

| Automotive | Enhanced safety and lightweight components | Shift towards lightweight materials for improved fuel efficiency | Increased adoption in electric vehicle production |

| Manufacturing | Versatility in forming and welding processes | Rise in precision manufacturing techniques | Stable growth driven by automation advancements |

| Shipbuilding | Corrosion resistance and strength | Increasing global shipping demands | Expected expansion in marine construction projects |