Choosing the right Carbon Steel Strip Coil for your project can be challenging. Many factors come into play that can impact your decision. This steel plays a vital role in various applications. From construction to automotive industries, its versatility is unmatched.

When selecting a Carbon Steel Strip Coil, consider its specifications. Thickness, width, and tensile strength are crucial. Different projects require different properties. It's important to reflect on the specific needs of your application. Sometimes, we overlook minor details that can significantly affect the outcome.

Quality matters. Not all carbon steel is created equal. You may find yourself questioning a choice later on. Take your time to compare options before committing. Engaging with suppliers can also provide valuable insights. The right coil can make a world of difference in your project's success.

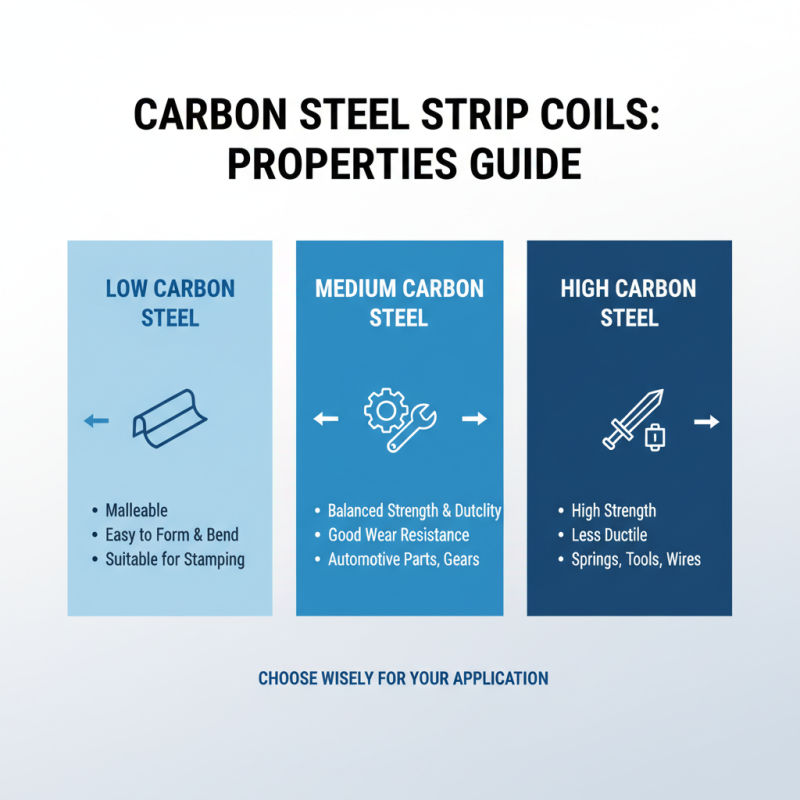

When selecting carbon steel strip coils, understanding their properties is crucial. These coils come in various grades, each designed for specific applications. The most common types include low carbon, medium carbon, and high carbon steel. Low carbon steel is malleable and easy to work with, suited for forming and bending tasks. On the other hand, high carbon steel boasts greater strength but is less ductile. Each has its own merits and drawbacks.

The thickness of the coil matters too. Thicker steel offers more strength but can be challenging to manipulate. Conversely, thinner steel is easier to handle but may not withstand heavy loads. Pay attention to the steel’s tensile strength and yield strength; these factors reveal how the material will perform under stress. Often, people choose without fully assessing the applications. This can lead to inefficiencies or project failures.

Another consideration is the finish of the strip coil. Options may include hot-rolled or cold-rolled finishes, which impact the surface quality and mechanical properties. Each method has unique benefits and potential issues. Ensuring you match the surface finish to your project’s needs is essential. Selecting the right carbon steel strip coil can be a complex task requiring careful thought and reflection on your project's demands.

Choosing the right carbon steel strip coil is essential for any project. It's crucial to consider several key factors. One of the most important is the coil's thickness. Industry standards indicate that coils thicker than 0.5 mm are often preferred for structural applications. However, thinner coils may be suitable for automotive and packaging uses. Understanding the specific need is vital.

Another factor is the steel's mechanical properties. Tensile strength and yield strength are critical metrics. According to a report by the World Steel Association, carbon steel strip coils should have a yield strength of at least 250 MPa for most applications. Buyers often overlook this aspect, leading to premature failures in projects.

Lastly, consider the surface finish. A smooth finish reduces friction and wear. Rough surfaces can increase maintenance needs and operational costs. About 35% of industry professionals report failures caused by inadequate surface quality. Selecting the right specifications can mitigate such risks. Remember to balance your project's requirements with these specifications.

| Dimension | Thickness (mm) | Width (mm) | Weight (kg) | Grade | Applications |

|---|---|---|---|---|---|

| Coil A | 1.0 | 1250 | 500 | SPCC | Automotive parts, appliances |

| Coil B | 0.8 | 1000 | 300 | S235JR | Construction, structural components |

| Coil C | 1.2 | 1500 | 600 | C45 | Machining, tools |

| Coil D | 0.5 | 800 | 200 | Q235B | General fabrication |

| Coil E | 1.5 | 1600 | 700 | ST52-3 | Heavy machinery, automotive |

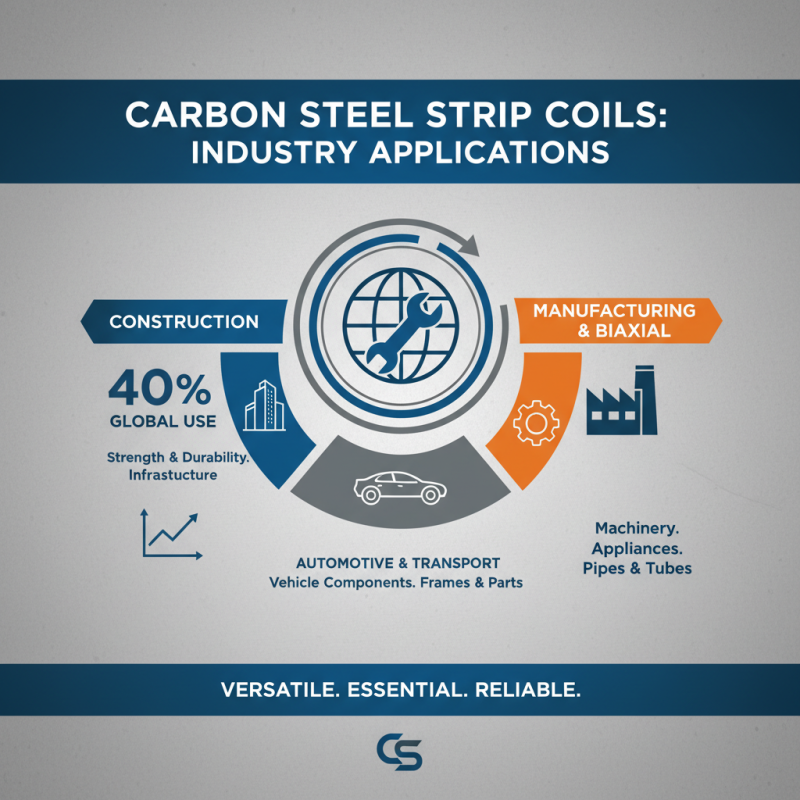

Carbon steel strip coils are widely used across various industries due to their unique properties. In construction, for example, they provide strength and durability. A report by Research and Markets indicates that the construction sector accounts for over 40% of carbon steel applications globally. This demonstrates the material's importance in supporting infrastructure projects.

In automotive manufacturing, carbon steel strip coils facilitate the production of critical components. Many auto parts, such as frames and body panels, rely on the strength of carbon steel. In fact, industry statistics suggest that about 60% of automotive parts are made from carbon steel alloys. This ensures vehicles can withstand daily wear and tear, contributing to safety and longevity.

When selecting carbon steel strip coils, consider these tips. Assess the material thickness and width based on your project's specifications. Ensure the coil's mechanical properties match the intended application. It’s crucial to carefully evaluate the surface treatment options. In some cases, the finish can affect performance and longevity. Remember, not all products are the same, and a wrong choice might lead to failure. Keep these details in mind to avoid costly mistakes.

When considering materials for projects, carbon steel strip coils stand out for their versatility. They provide excellent durability and strength, making them suitable for various applications. In contrast, aluminum and stainless steel often offer lighter weights but at the cost of reduced strength in certain scenarios. Users may find themselves reevaluating whether weight or sturdiness is more critical for their needs.

Carbon steel excels in environments requiring heavy-duty performance. However, it can be susceptible to corrosion if not treated properly. This is where stainless steel shines; it withstands rust and general wear. Yet, its higher cost can deter some project managers. On the other hand, aluminum strips weigh less and can be easier to handle. Yet, aluminum can bend under pressure, while carbon steel maintains its form.

Choosing the right material is not always straightforward. Project-specific requirements may clash with budget constraints. For instance, using carbon steel might seem cost-effective but can lead to maintenance issues later on. Alternatively, opting for stainless steel could blow the budget. Consider each option’s lifecycle carefully. Your choice impacts both performance and costs down the line.

When sourcing carbon steel strip coils, focus on quality and specifications. Inspect the material carefully. Look for the right thickness and width. The right dimensions impact your project's success. Ensure that your supplier provides detailed technical data sheets. These sheets must outline tensile strength and hardness. Understanding these properties will guide your decision.

Maintaining carbon steel strip coils is crucial for longevity. Store them in a dry environment to prevent rust. Check for any signs of corrosion periodically. Cleaning the coils with a protective oil can help. But remember, not all oils are equal. Some may leave residues. This could affect the quality of your work.

Choosing the right coil should not be rushed. Take the time to evaluate options. Consider consulting with experts if you're unsure. Reflect on your previous projects to understand what worked and what didn't. Each experience helps you make better choices in future sourcing endeavors.