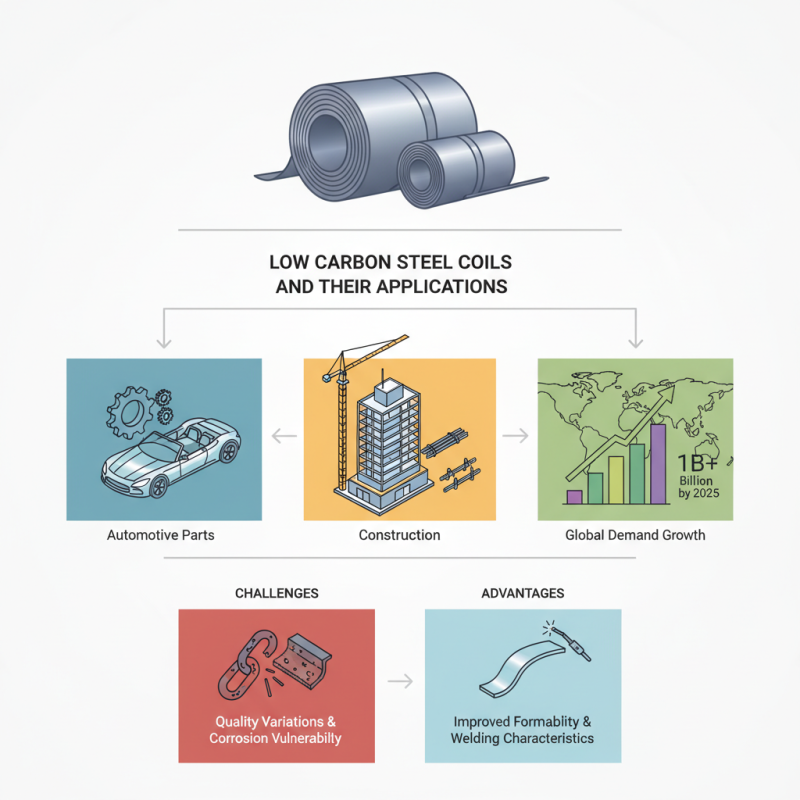

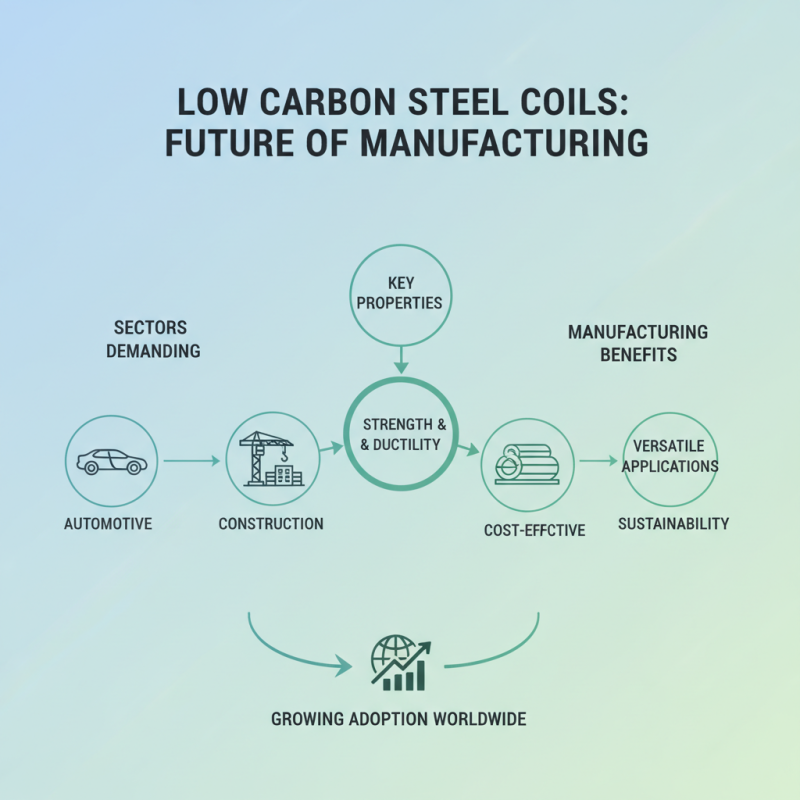

Low carbon steel coils, particularly Steel Coils Low Carbon Strips, are essential materials in various industries. These coils are known for their malleability and ductility, making them ideal for applications like automotive parts and construction. According to a recent report by Market Research Future, the global demand for low carbon steel is projected to reach over 1 billion tons by 2025, emphasizing its vital role in industrial growth.

Expert David Richter, a well-known analyst in the steel industry, noted, "The versatility of Steel Coils Low Carbon Strips makes them a preferred choice among manufacturers." This statement reflects the growing reliance on low carbon steel in modern applications. Its lower carbon content offers unique advantages, such as improved formability and welding characteristics, further driving its adoption.

However, the industry faces challenges. The quality of the raw materials used can vary, leading to inconsistencies in final products. As production ramps up to meet demand, ensuring uniformity remains a pressing task. Low carbon steel is still vulnerable to corrosion, which can affect its longevity. Stakeholders need to balance the benefits with these limitations as they innovate and improve production processes.

Low carbon steel coils are products made from steel with a low carbon content, typically less than 0.3%. This composition provides several advantages, including improved malleability and ductility. As a result, they are versatile materials in various industries. According to a recent market analysis, low carbon steel accounts for nearly 70% of global steel consumption.

The properties of low carbon steel coils make them ideal for numerous applications. They are frequently used in construction, automotive parts, and manufacturing of appliances. Their strength and formability allow for various shapes and sizes. Low carbon steel can be easily welded and machined, enhancing its usability. However, it tends to rust more easily than higher carbon steel.

Tip: Consider applying a protective coating to low carbon steel to prevent corrosion.

Manufacturers often face challenges with low carbon steel. The balance between strength and ductility can complicate the production process. Additionally, while low carbon steel is cost-effective, it may not always meet the performance requirements for specific applications. Understanding these limitations is crucial for those selecting materials for their projects.

Tip: Always consult with material specialists to choose the right steel grade for your needs.

Low carbon steel coils offer unique benefits that set them apart from other steel grades. They have a lower carbon content, usually under 0.25%. This composition provides improved ductility and malleability. However, they may lack the strength of higher carbon steels. For some applications, this reduction in strength might be a downside.

When comparing low carbon steel coils with medium and high carbon steels, one can observe several differences. Medium carbon steels, containing up to 0.6% carbon, are tougher and can be heat-treated. They are suitable for applications like automotive components. High carbon steels, with over 0.6% carbon, provide superior hardness but can be brittle. In contrast, low carbon steel coils are preferred for applications where flexibility is critical.

Applications like construction and manufacturing benefit greatly from low carbon steel. The flexible nature allows for easier shaping. Yet, one might need to consider the trade-offs. While they are great for forming, low carbon steels may not perform as well under heavy load situations. It's essential to assess the requirements of each project before making a decision. Each steel grade has its strengths and weaknesses; understanding them is key.

Low carbon steel coils are widely used in various applications due to their versatility and ease of manufacture. The production process begins with the melting of scrap metal in a furnace, which creates molten steel. This process requires precise temperature control. After melting, the steel undergoes refinement to reduce carbon content. This is crucial, as low carbon content enhances ductility.

Next, the molten steel is cast into slabs or billets. These shapes are then reheated and rolled into coils. Hot rolling is a common technique. It involves passing the heated steel through rollers to achieve the desired thickness. This creates a uniform structure, though it may introduce surface imperfections that require attention.

Cold rolling can follow hot rolling. This process further reduces thickness in a controlled environment. It improves surface finish and dimensional accuracy. However, it can lead to increased brittleness. Each stage of manufacturing presents its own challenges and requires careful management. Understanding these processes helps in utilizing low carbon steel coils more effectively for construction, automotive, and other industries.

| Property | Value | Applications | Manufacturing Process |

|---|---|---|---|

| Carbon Content | 0.05% - 0.25% | Automotive Components | Cold Rolling |

| Tensile Strength | 370 - 550 MPa | Structural Support | Hot Rolling |

| Ductility | Good | Sheet Metal Fabrication | Annealing |

| Corrosion Resistance | Moderate | Manufacture of Pipes | Coating (Galvanizing) |

| Weldability | Excellent | Construction | Welding Processes |

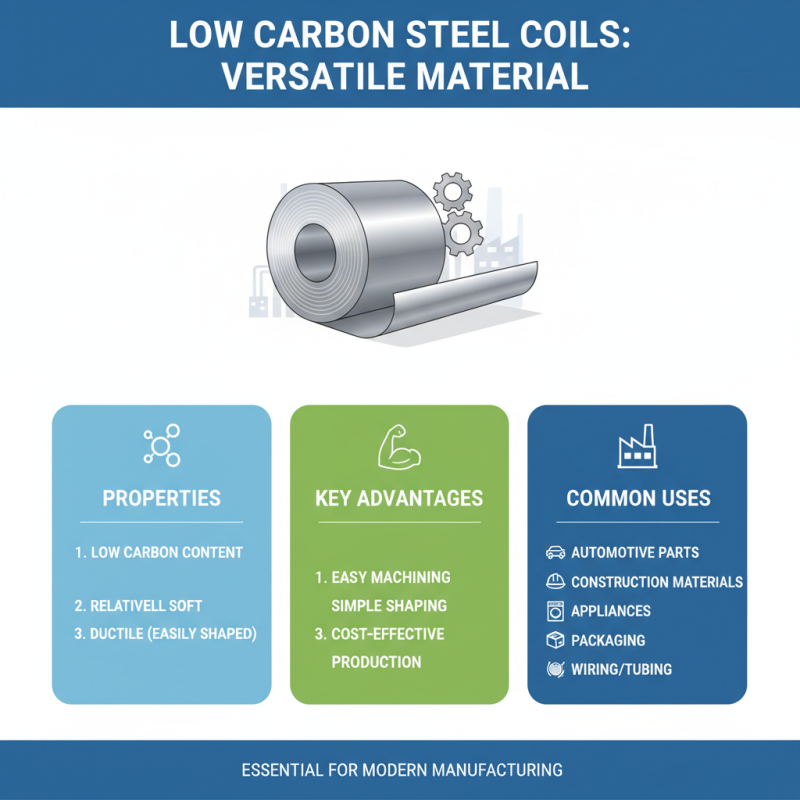

Low carbon steel coils are a versatile material widely used across various industries. Their low carbon content makes them relatively soft and ductile. This property facilitates easy machining and shaping, making them ideal for manufacturing processes.

In the automotive industry, these coils are essential. They are used for producing body panels, frames, and components. Their strong yet malleable characteristics allow vehicles to maintain safety without compromising weight. In construction, low carbon steel coils provide structural integrity to buildings. They are often found in beams and columns, showing resilience under pressure.

Low carbon steel also plays a role in appliance manufacturing. Items like refrigerators and washing machines often contain parts made from these coils. However, there is a downside. The low carbon steel can rust if not properly coated. Ensuring longevity may require extra measures, like regular maintenance or protective paints. There’s still room for improvement in sustainability. As industries seek greener alternatives, the production process of low carbon steel needs to evolve.

Low carbon steel coils are gaining traction in various sectors. Their strength and ductility make them ideal for manufacturing. As demand increases, industries look for cost-effective solutions. This trend is especially prominent in automotive and construction markets. Many manufacturers seek these coils due to their favorable properties.

Looking ahead, the market for low carbon steel coils shows promising growth. Sustainability is becoming a focal point for manufacturers. More companies are exploring eco-friendly production methods. However, challenges remain. The balancing act of quality and cost continues to affect decisions. Innovations in processing techniques may help ease these concerns. It’s crucial for businesses to assess their strategies moving forward. Rising raw material costs could impact profit margins. Adapting to fluctuations will be vital for long-term success.