In recent years, the demand for Steel Coils Low Carbon Strips has surged, reflecting a significant shift towards sustainable manufacturing practices. According to a report by the International Steel Association, low carbon steel production has increased by approximately 15% globally over the last decade, driven by its favorable mechanical properties and lower environmental impact compared to higher carbon alternatives.

The versatility of these low carbon steel strips makes them ideal for various applications ranging from automotive components to construction materials, highlighting their role in enhancing efficiency and reducing weight in manufacturing processes.

As industries strive to meet stringent emissions regulations and optimize resource utilization, the adoption of Steel Coils Low Carbon Strips is poised to transform modern manufacturing, paving the way for innovative solutions that align with sustainable development goals.

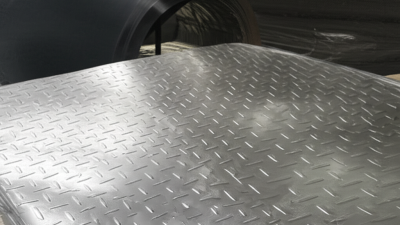

Low carbon steel coils are pivotal in modern manufacturing due to their unique characteristics that cater to a variety of industrial applications. With a carbon content typically ranging from 0.05% to 0.25%, these coils exhibit excellent ductility and weldability. This property allows manufacturers to fabricate complex shapes with minimal risk of cracking during the forming process. Additionally, the malleability of low carbon steel makes it ideal for processes that require extensive shaping and bending, thereby enhancing the versatility of manufacturing operations.

Incorporating low carbon steel coils into production lines also brings about significant economic advantages. Their cost-effectiveness, combined with strength and durability, makes them a preferred choice for industries ranging from automotive to construction. Manufacturers can achieve lightweight designs without compromising strength, leading to improved energy efficiency in end products.

Furthermore, the corrosion resistance of coated low carbon steel facilitates longer product lifespans, reducing maintenance costs over time. As industries strive for sustainable practices, low carbon steel coils emerge as a key material in the quest for reducing overall environmental impact while ensuring high-quality manufacturing outputs.

Low carbon steel coils have become increasingly significant in modern manufacturing processes, offering a plethora of benefits that enhance production efficiency and product quality. One of the key advantages is their excellent formability, which allows manufacturers to create complex shapes with ease. According to a report by the World Steel Association, the malleability of low carbon steel contributes to its dominance in the automotive and construction industries, where intricate designs are paramount.

Moreover, low carbon steel coils exhibit superior weldability and strength-to-weight ratios, making them ideal for applications that require durability without adding excessive weight. The American Iron and Steel Institute notes that components made from low carbon steel can reduce overall manufacturing costs by minimizing material waste and shortening production times. These features not only streamline the manufacturing process but also enhance the overall sustainability of operations, as more efficient use of materials aligns with contemporary eco-friendly practices. The growing trend towards sustainable production methods further underscores the importance of integrating low carbon steel coils into modern manufacturing strategies.

Low carbon steel coils have emerged as a vital component across various industries, playing a significant role in modern manufacturing processes. These versatile materials are characterized by their excellent ductility and malleability, making them ideal for applications ranging from automotive components to household appliances. According to a market analysis by Research and Markets, the global low carbon steel market is expected to grow at a CAGR of 4.5% from 2021 to 2026, driven by the increasing demand for lightweight and energy-efficient products.

Low carbon steel coils have emerged as a vital component across various industries, playing a significant role in modern manufacturing processes. These versatile materials are characterized by their excellent ductility and malleability, making them ideal for applications ranging from automotive components to household appliances. According to a market analysis by Research and Markets, the global low carbon steel market is expected to grow at a CAGR of 4.5% from 2021 to 2026, driven by the increasing demand for lightweight and energy-efficient products.

In the automotive sector, low carbon steel coils are used in manufacturing body panels and structural components, contributing to vehicle safety while minimizing weight. Furthermore, industries such as construction and consumer goods are leveraging these coils due to their cost-effectiveness and recyclability. Steel Innovations' latest report suggests that implementing low carbon steel can lead to a reduction in carbon emissions by up to 30%, showcasing its environmental benefits alongside its practical applications.

Tip: When selecting low carbon steel coils for your projects, consider sourcing from suppliers who adhere to sustainable practices, ensuring that you’re not only meeting industry standards but also contributing to a greener manufacturing process.

Another interesting application lies in electronics, where low carbon steel springs and connectors are imperative for device functionality. In fact, the precision of low carbon steel in electronics manufacturing allows for enhanced durability and performance, making it a material of choice for innovative gadgets.

Tip: Stay updated on the latest advancements in low carbon steel technologies, as they can provide your manufacturing process with improved efficiency, leading to better product outcomes.

Low carbon steel coils have emerged as a pivotal component in modern manufacturing processes, primarily due to their adaptability and environmental benefits. Integrating these materials into manufacturing workflows necessitates a focus on innovative techniques and sustainable practices. For instance, the advancement of integration technologies in steel production has significantly streamlined the manufacturing interface. This allows for improved efficiency and reduced resource waste, aligning well with the principles of a circular economy.

As companies embrace low carbon steel, best practices for their integration become crucial. Manufacturers should prioritize energy efficiency and waste minimization, adopting practices that emphasize recycling and the sustainable sourcing of raw materials. Furthermore, fostering a culture of innovation within the workforce promotes the exploration of green technologies and methods. By adopting these best practices, manufacturers can not only enhance their operational performance but also contribute to the broader goal of environmental sustainability in the industry.

Low carbon steel coils have emerged as a key player in modern manufacturing, not just due to their mechanical properties but also their role in promoting sustainability. According to the World Steel Association, the production of low carbon steel results in significantly reduced carbon emissions compared to higher carbon alternatives, with an average reduction of approximately 30%. This is particularly relevant as industries strive to meet international sustainability goals and reduce their environmental footprint. The lightweight nature of low carbon steel also allows for energy savings during transportation, aligning with best practices in supply chain management.

Recent studies indicate that adopting low carbon steel can lead to a notable decline in the environmental impact of manufacturing processes. The International Energy Agency (IEA) reports that transitioning to lower carbon materials can reduce energy consumption in production by up to 15%. Moreover, implementing low carbon steel in manufacturing not only promotes environmentally friendly practices but also enhances product lifecycle management, leading to higher recycling rates. It is estimated that 85% of low carbon steel can be recycled without loss of properties, which makes it an excellent choice for manufacturers aiming to adopt a circular economy model.