Choosing the right Carbon Steel Strip Coil is crucial for any project. Expert James Richards, a leading figure in the steel industry, states, “The right coil can enhance both durability and performance.”

When selecting Carbon Steel Strip Coil, consider its thickness and tensile strength. These factors will affect the overall effectiveness of your project. Many customers overlook dimensions, only to regret it later. Proper measurements are essential to avoid complications.

In addition to specifications, assess the coil’s coating options. The finish can impact both appearance and longevity. Some finishes may lead to rust if not properly chosen. Take the time to research and understand the products available. This can prevent costly mistakes down the line. Selecting the right Carbon Steel Strip Coil means understanding your project's unique needs, reflecting on past choices, and avoiding oversights.

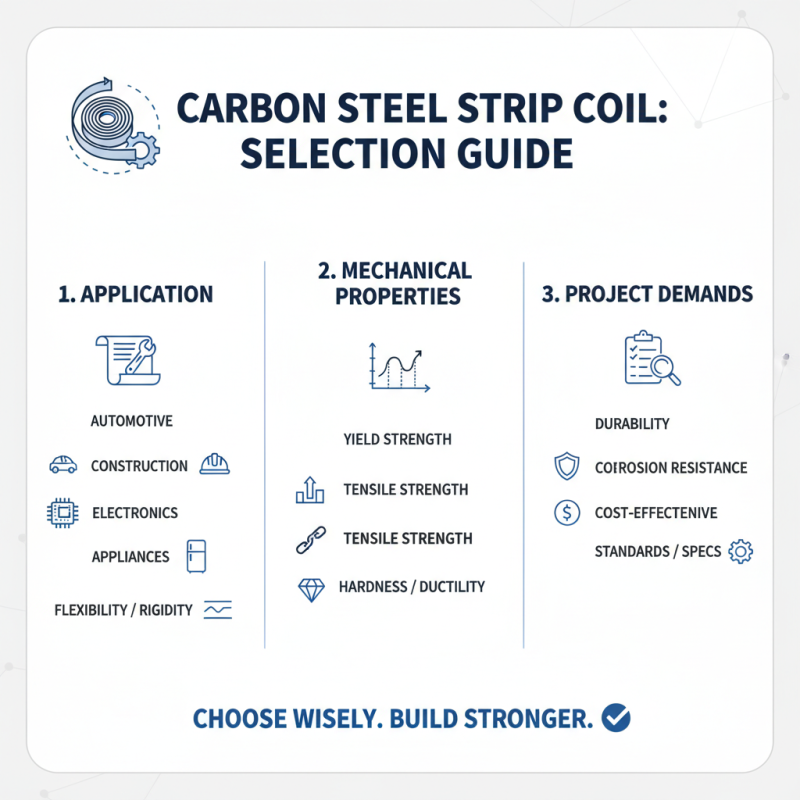

Choosing the right carbon steel strip coil for your project requires careful consideration. The application plays a vital role. Different projects may require specific properties, such as strength or flexibility. Evaluate the mechanical properties of the steel, including yield strength and tensile strength. Understand the application's demands before making a decision.

When selecting carbon steel strip coils, think about the thickness and width. These factors impact performance and suitability. A thicker coil may provide more strength but can be less flexible. Width selection depends on the intended use. You may need to find a balance between strength and flexibility for optimal results.

Tips: Always ask for samples. Testing the material can reveal more than specifications alone. Don't overlook the importance of surface finish. A rough finish may lead to issues in certain applications. Remember, not every coil is perfect. Analyze any imperfections seriously. They can affect your project’s success in unexpected ways.

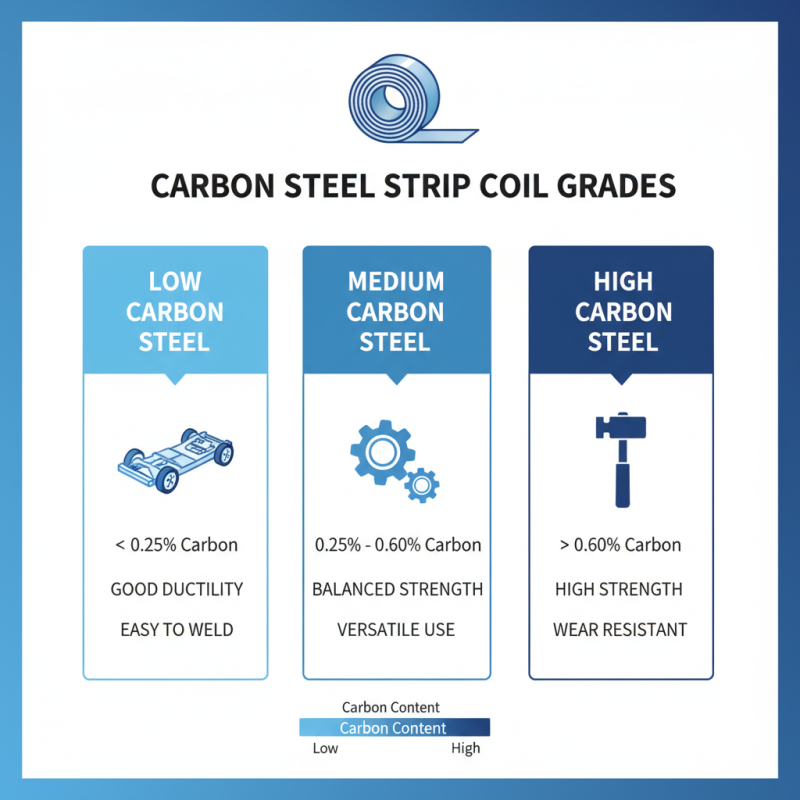

When selecting carbon steel strip coil, understanding its different grades is crucial. Carbon steel is classified based on its carbon content. Grades typically range from low to high carbon. Low carbon steel often contains less than 0.25% carbon. It offers good ductility and weldability, making it suitable for construction and automotive applications.

Higher carbon content, around 0.30% to 0.70%, enhances strength and hardness. However, it may reduce ductility. Middle grades are versatile, balancing strength and formability. According to industry reports, over 40% of carbon steel used in manufacturing falls within this middle range. Not all projects require high-strength steel. It’s vital to consider the intended application when selecting a grade.

Quality control is essential in steel production. Minor impurities or variations can significantly affect performance. A flawed batch can lead to project delays or failures. Regular testing and proper documentation of grades are necessary for transparency. Keep in mind that improper selection of grades could impact long-term durability.

When selecting a carbon steel strip coil, it’s crucial to evaluate key specifications that impact its performance. One important factor is the thickness of the coil. Typically, thickness can range from 0.1 mm to 3 mm. A report from the American Iron and Steel Institute (AISI) highlights that coils thinner than 0.5 mm may lack sufficient strength for certain applications. Therefore, it’s essential to match the thickness with your project’s requirements.

Another critical specification is the chemical composition. Carbon content significantly affects the steel’s hardness and tensile strength. A higher carbon content can improve strength but may reduce ductility. According to industry standards, the carbon content in carbon steel ranges from 0.05% to 2.0%. A deeper understanding of these attributes can lead to better material choices. However, striking the right balance can be challenging.

Coil width is another specification to consider. Common widths range from 30 mm to 600 mm, but custom sizes are available. It’s vital to measure precisely to avoid waste and inefficiencies. A study shows that improper width selection can increase costs by up to 15%. Beyond these metrics, surface finish and treatment options should also be assessed. Factors like galvanization can enhance corrosion resistance, yet may add complexity to processing. These details matter and warrant careful deliberation during the selection process.

Carbon steel strip coils find extensive applications across numerous industries. In the automotive sector, these coils are essential for manufacturing parts. They provide strength and durability for components like body panels and frames. Many manufacturers rely on carbon steel for its robust properties. It shapes easily into complex designs, making it a go-to choice.

In construction, carbon steel strip coils are widely used for making beams and reinforcement bars. Their resistance to bending allows for safer and sturdier structures. However, the challenge lies in choosing the right thickness and width for specific projects. Selecting coils without proper requirements can lead to inefficiencies. This often results in added costs or project delays.

Food packaging also utilizes carbon steel strip coils. Their protective qualities help in preserving food life. Yet, it is crucial to ensure that the coils are treated for safety. Improper treatment can risk contamination. Users must be aware of these details when selecting materials. Understanding these aspects is vital for making effective choices in varied applications.

When sourcing carbon steel strip coils, quality is paramount. Start by identifying your specific needs. Consider thickness, width, and intended use. Each project has unique requirements that must be met. Research and verify the material specifications to ensure they align with your expectations.

Tip: Look for suppliers with a solid reputation. Check reviews and testimonials. Feedback from previous clients can be very revealing. A trustworthy supplier should be open to questions and provide clear answers about their products.

Inspection of the coils is crucial. Visual checks for rust, dents, or scratches can save you from future headaches. These imperfections might seem minor but can impact the final product’s performance.

Tip: Request sample coils before committing to large orders. Testing samples under real project conditions can help identify any potential issues early. Pay attention to how the material behaves during processing.

Lastly, consider the cost. While it’s tempting to choose the cheapest option, the long-term returns often come from investing in quality. Don't ignore the hidden costs that faulty materials might bring.