Choosing the right materials for your project is vital. Steel Coils Low Carbon Strips are a popular choice due to their versatility. These strips offer strength and durability, making them suitable for various applications.

When selecting Steel Coils Low Carbon Strips, consider several factors. Think about the specific requirements of your project. The thickness, width, and length of the strips can greatly impact performance. Additionally, the carbon content affects welding properties and flexibility. Understanding these details helps you make informed choices.

Sometimes, the selection process can lead to confusion. You may find numerous options that seem similar. It might take time to determine the best fit. Reflecting on past experiences with material selection can guide you. Balancing quality and cost is often a challenging task. Remember, the right choice can significantly impact the outcome of your project.

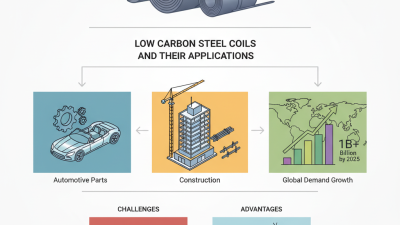

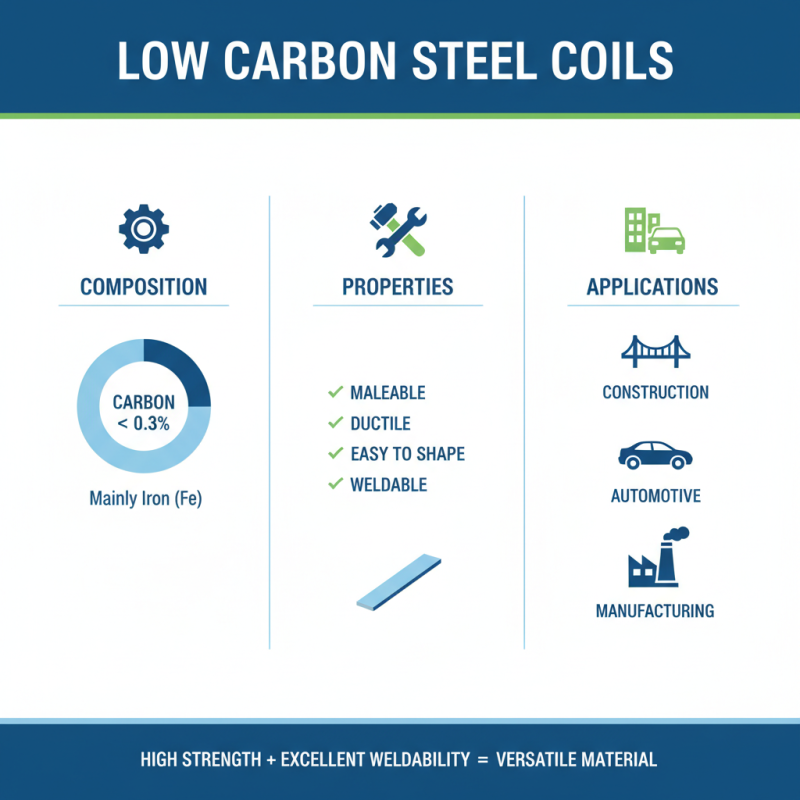

Low carbon steel coils are essential materials in various projects. They contain a low carbon content, typically below 0.3%. This makes them malleable, ductile, and easy to work with. Such properties are crucial for applications requiring bending and shaping. High strength is combined with excellent weldability, making them ideal for construction, automotive, and manufacturing industries.

These steel coils find utility in multiple sectors. For instance, they are widely used in making structural components, metal furniture, and storage tanks. However, potential buyers should be cautious. Not all low carbon steels are created equal. Variations exist in strength and thickness. Knowing the specific requirements of your project is vital. Sometimes, a less strong coil may not provide the necessary durability.

When deciding on steel coils, consider the entire project's demands. Choose the appropriate grade and finish for better results. Overlooking these details can lead to failures. It's essential to reflect on your choices and adjust them accordingly. Steel selection should be a well-thought-out process. Taking time to research is not wasted. You can save resources and time in the long run.

When choosing steel coils for your project, it's essential to identify the right type. Low carbon steel strips are popular due to their flexibility and durability. They are ideal for applications that require easy forming and welding. Understanding the specific properties of these strips is crucial.

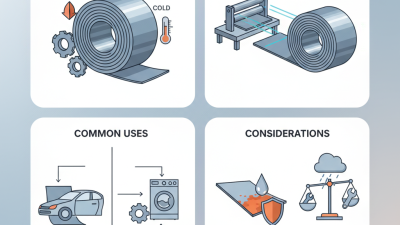

There are various types of steel coils. Hot-rolled strips are common. They tend to be less expensive but might have a rougher surface. Cold-rolled strips offer smoother finishes, ideal for aesthetic applications. However, they come at a higher cost. Consider what matters most for your project.

**Tip:** Always inspect the coil's thickness. A small variation can affect your project's outcome. Additionally, consider future needs. Will you change the design later? Anticipating such factors can save time and costs.

Low carbon steel can rust if not properly coated. Think about the environment where the steel will be used. Sometimes, a protective layer might be necessary to extend longevity. Proper storage is also critical. If coils sit outdoors, they may suffer damage. Reflect on these aspects to make the best choice.

| Type of Steel Coil | Chemical Composition | Thickness (mm) | Width (mm) | Mechanical Properties | Applications |

|---|---|---|---|---|---|

| Low Carbon Steel Coil | C: 0.05-0.25%, Mn: 0.3-0.9% | 0.5 - 3.0 | 1000 - 1500 | Yield Strength: 200-350 MPa | Automotive parts, Construction |

| High Strength Low Alloy (HSLA) Coil | C: 0.05-0.12%, Cu: 0.2-0.5% | 1.0 - 5.0 | 1200 - 2000 | Yield Strength: 300-450 MPa | Infrastructure, Shipbuilding |

| Cold Rolled Steel Coil | C: 0.06-0.15%, Mn: 0.3-0.7% | 0.3 - 2.0 | 800 - 1200 | Yield Strength: 210-330 MPa | Appliances, Electrical Equipment |

When selecting low carbon steel strips, it’s crucial to evaluate their key properties. Low carbon steel typically contains less than 0.3% carbon. This property results in excellent weldability and ductility, making it a preferred choice for various applications. According to industry reports, low carbon strips can provide tensile strength ranging from 275 to 400 MPa. Such characteristics are vital for construction and manufacturing processes.

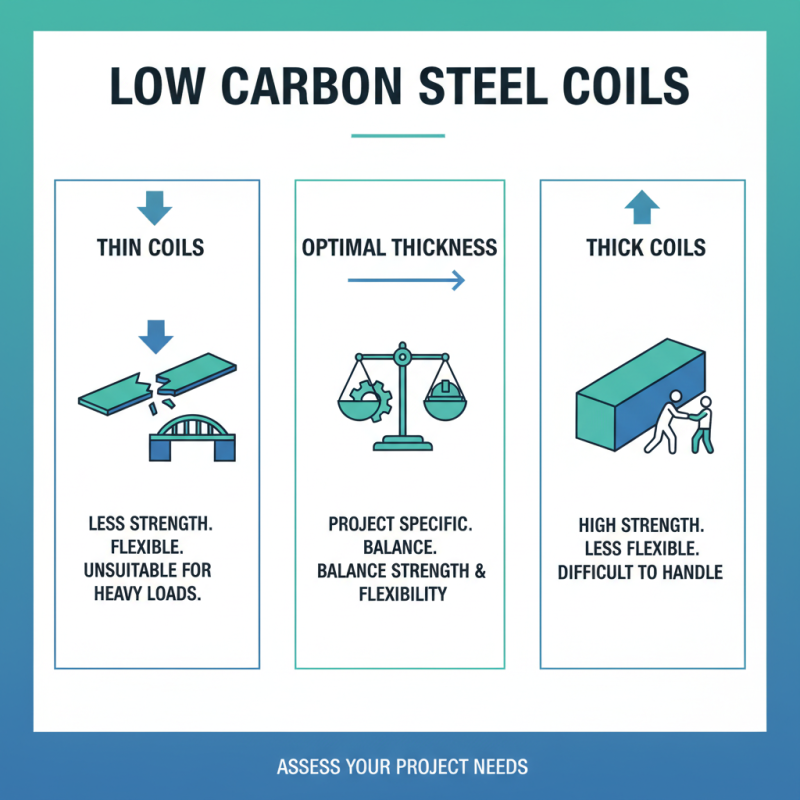

Another important aspect is the strip’s thickness and width. These dimensions can significantly affect performance in specific applications. Industry standards suggest a thickness ranging from 0.2 mm to 6 mm. While thinner strips may offer flexibility, they might also have limitations with load-bearing capacities. So, it’s essential to balance the need for strength with flexibility.

Processing techniques also play a role in the quality of these strips. Techniques like cold rolling can enhance the surface finish but might lead to unexpected weaknesses. Some manufacturers report issues with surface defects. Regular quality inspections can help mitigate these concerns. Ultimately, understanding these properties will help make better decisions for your projects.

When sourcing low carbon steel coils for projects, consider the thickness. The thickness affects strength and flexibility. A coil that is too thin may not support the weight. Conversely, excessive thickness can make handling difficult. Each project's requirements will differ, so assess your specific needs carefully.

Next, look at mechanical properties. These include yield strength, tensile strength, and ductility. Understanding these aspects helps in selecting the right material for your application. Sometimes, manufacturers provide data sheets. Yet, not all data is clear cut or easy to interpret. Misleading information can lead to poor choices.

Lastly, consider delivery logistics and lead times. Manufacturing processes vary, and delays can affect your project timeline. Think about transportation costs as well. They may add to your expenses. Coordinating with suppliers can help avoid costly mistakes. Investing time in the sourcing process is vital to ensure project success.

When working with low carbon steel strips, understanding their properties is crucial. These strips are malleable and ductile, making them suitable for various applications. They can easily be formed into desired shapes without cracking. This characteristic is particularly beneficial in construction and manufacturing.

Tip: Always consider the thickness of the strips. Thinner strips are more flexible but may not withstand heavy loads. Balance is key.

Proper storage is also important. Humidity can lead to rust and corrosion. Keeping the strips in a dry environment helps maintain their quality. Furthermore, inspect the strips regularly for any signs of damage before use.

Tip: Using protective coatings can enhance durability. Simple solutions like oil or paint can prevent oxidation.

In production, ensure safety measures are in place. Low carbon steel can be sharp and heavy. Injuries can occur if not handled carefully. Always use appropriate gear and tools for cutting and shaping.

Working with low carbon steel requires care and consideration. The ease of manipulation is an advantage, but sometimes it can lead to complacency. Reflecting on your processes can help improve project outcomes.