In the construction and manufacturing industries, choosing the right materials can greatly impact project outcomes. One popular option is Carbon Steel Coil Cold Roll. According to industry expert Dr. Emily Carter, “Carbon Steel Coil Cold Roll offers an excellent balance of strength and flexibility.” This makes it a valuable choice for various applications.

Carbon Steel Coil Cold Roll is known for its durability. It resists wear and tear effectively. Many engineers appreciate its capacity to be easily shaped into different designs. However, there are challenges in sourcing high-quality materials. Not all suppliers meet the necessary standards. This inconsistency can lead to project delays.

Moreover, while Carbon Steel Coil Cold Roll is affordable, the long-term benefits must be considered. Short-term savings might lead to higher costs later. Understanding these dynamics is crucial for optimal decision-making in material selection. Each project requires careful evaluation.

When it comes to construction projects, carbon steel coil cold roll offers numerous advantages. This material is known for its strength and durability. It provides excellent support for structures, ensuring long-lasting results. The application of this steel type can range from framing to roofing. Builders often appreciate its lightweight nature, making it easier to handle and install.

Moreover, carbon steel coil cold roll is quite versatile. It can be easily shaped and molded to fit specific design requirements. This adaptability allows for innovative designs without compromising safety. However, it’s essential to consider potential corrosion issues. Proper treatment and coatings can mitigate these risks. Not all projects may need this level of steel; assessing your needs is vital.

Cost efficiency is another reason to choose carbon steel coil cold roll. It often comes at a more affordable price than alternatives. However, this cost-effectiveness should not cloud your judgment. Sometimes, higher-quality materials may save money in the long run. Balancing budget constraints with project durability is crucial for success.

Carbon steel coil cold roll finds extensive applications across various industries due to its versatility and strength. In the automotive sector, manufacturers utilize this material for body panels and frames. The durability of carbon steel supports safety and longevity, yet there are concerns about corrosion resistance. Without proper coating, components can degrade over time.

In construction, carbon steel coil cold roll is key for structural support. It's often used in beams and columns. This allows for sturdy frameworks. However, miscalculating the material's load-bearing capacity can lead to significant issues. Engineers must ensure they choose the proper gauge to avoid failure.

Moreover, in the appliance industry, this material is favored for making various components. From washing machines to refrigerators, many appliances rely on carbon steel's mechanical properties. Yet, it requires careful handling during manufacturing. Any defects can compromise the final product. Balancing cost and quality remains a challenge in production.

| Industry | Applications | Benefits |

|---|---|---|

| Automotive | Body panels, chassis components | High strength, lightweight, cost-effective |

| Construction | Structural beams, sheet metal | Durability, versatility, easy to weld |

| Manufacturing | Industrial machinery, tools | Precision, high machinability, strength |

| Electrical | Electrical enclosures, components | Corrosion resistance, thermal conductivity |

| Aerospace | Aircraft structures, components | Lightweight, strength-to-weight ratio |

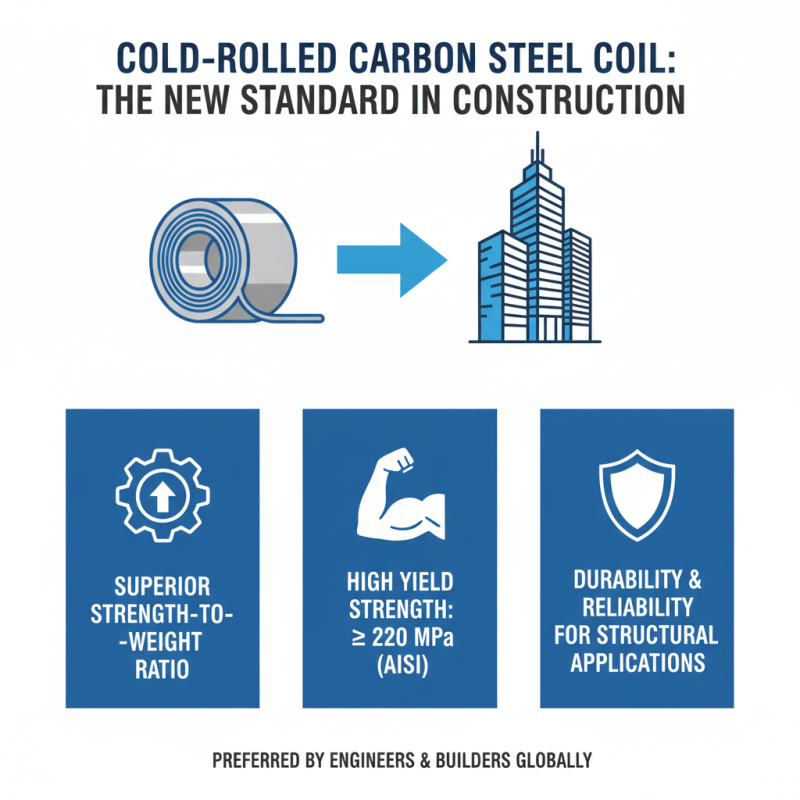

When it comes to metal materials, carbon steel coil cold roll stands out. Its strength-to-weight ratio is impressive. This makes it a preferred choice in many construction projects. According to the American Iron and Steel Institute, cold-rolled carbon steel can achieve yield strengths of 220 MPa and higher. This is crucial for structural applications.

In comparison with other materials, such as aluminum and stainless steel, carbon steel allows for better toughness at room temperature. While aluminum is lighter, it lacks the same tensile strength. Stainless steel, on the other hand, is often more expensive and requires more complex fabrication processes. A 2022 report from the World Steel Association noted that carbon steel’s cost-effectiveness is hard to beat, making it a budget-friendly option.

However, it’s important to note that carbon steel is prone to corrosion. Projects in humid environments necessitate protective coatings or regular maintenance. This could increase long-term costs. Moreover, the material is sometimes less malleable than other metals, which can lead to challenges during shaping. Awareness of these drawbacks is essential for effective project planning.

When selecting carbon steel coil cold roll for your projects, several key factors come into play. First, consider the thickness of the coil. Thinner coils offer flexibility, which is great for complex shapes. However, they may lack the strength needed for heavy-duty applications. A careful balance is essential to achieve the desired performance.

Another important factor is the finish quality. Cold rolled carbon steel usually has a smooth surface. This can enhance aesthetic appeal when used in visible areas. Yet, a smooth finish might not always provide the grip needed for welding. Think about the final application and whether the appearance or the functionality is a priority.

Don't forget the mechanical properties. Carbon content affects strength and ductility. Higher carbon content creates stronger materials, but they can be less malleable. A middle ground is often beneficial. Testing and validating these properties are crucial, as flaws may go unnoticed until it’s too late. Understanding your specific project requirements helps ensure a successful outcome.

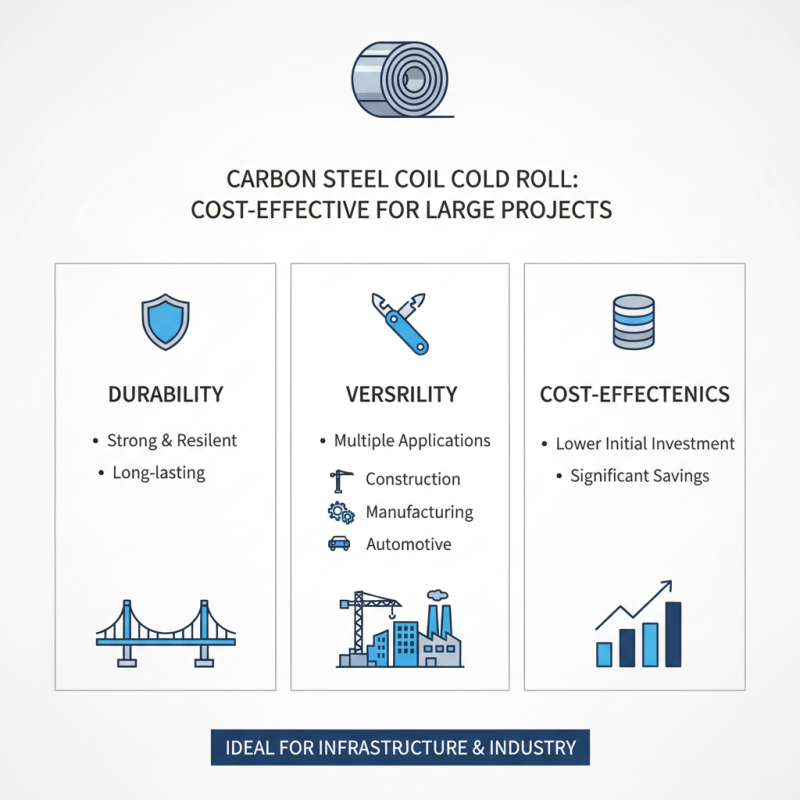

When considering materials for large scale projects, carbon steel coil cold roll stands out for its cost-effectiveness. This form of steel is both durable and versatile, making it ideal for various applications. It can be used in construction, manufacturing, and automotive sectors, among others. The initial investment in carbon steel coil cold roll is often lower compared to other materials, leading to significant savings.

However, quality can vary. It's essential to assess suppliers carefully. Some may offer lower prices, but the trade-off could be reduced performance. A slight compromise on quality can lead to bigger problems down the road. It's vital to ensure that the selected steel meets specific project standards. The thickness and tensile strength of the coil must align with the project’s demands.

Moreover, processing costs should be considered. Cold rolling can enhance the properties of the steel, but it might require more energy and labor. Understanding these factors is crucial. Although carbon steel coil cold roll is a wise option, project managers need to evaluate all aspects to avoid unforeseen expenses.