As the global demand for high-quality materials intensifies, carbon steel checkered coils have emerged as a vital component in various industries, notably in construction, automotive, and manufacturing. According to a recent report by the World Steel Association, the demand for carbon steel products is projected to rise by 2.3% annually, emphasizing the necessity for superior manufacturing processes and raw material selection. In this competitive landscape, Chinese manufacturers have been at the forefront, known for their ability to deliver robust and reliable carbon steel checkered coils. However, selecting the right manufacturer is crucial for global buyers seeking to ensure not only quality but also compliance with international standards. This blog will guide you through the key characteristics to look for in a quality manufacturer, ensuring that you invest wisely in carbon steel checkered coils that meet your specific needs.

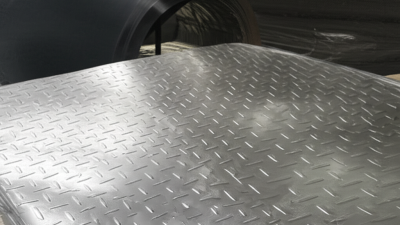

In the industrial sector, carbon steel checkered coils have emerged as a vital material, providing robust solutions for a variety of applications. Known for their unique surface texture, these coils not only enhance grip but also exhibit excellent durability, making them ideal for industries ranging from automotive to construction. The non-slip surface they offer is crucial for ensuring safety in environments where heavy machinery is in use. Moreover, carbon steel’s inherent strength allows for significant load-bearing capacities, enabling manufacturers to utilize lighter designs without compromising structural integrity.

Recent advancements, particularly in the analysis and optimization of coil springs for vehicles, indicate a growing interest in composite materials. However, traditional carbon steel components continue to maintain a strong presence due to their reliability and cost-effectiveness. As the industry explores new material innovations, it is essential to recognize the enduring advantages of carbon steel checkered coils. Their versatility and performance set a benchmark that newer materials must meet, ensuring they provide equal or greater benefits in real-world applications. The synergy of established materials with emerging technologies will likely shape the future landscape of industrial manufacturing.

As global industries continue to evolve, the demand for high-quality carbon steel products is becoming ever more pronounced. Manufacturers and buyers alike are beginning to recognize the importance of selecting materials that not only meet but exceed industry standards. China, as a leading producer, is positioning itself to cater to this growing need by ensuring that carbon steel checkered coils are made with precision and durability. Understanding the specific requirements of global markets is crucial for maintaining competitive advantage and meeting customer expectations.

Tip: When evaluating suppliers, always request certification and test results to ensure that the materials meet international quality standards. This verification process helps in establishing trust and guarantees that the products are suitable for your specific applications.

Around the world, industries such as construction, automotive, and manufacturing are calling for robust materials that can withstand demanding conditions. Carbon steel checkered coils, known for their slip-resistant surfaces, are particularly sought after. It's essential for buyers to understand the various grades and compositions of carbon steel to make informed decisions that align with their project specifications.

Tip: Consider engaging with suppliers who have a strong track record in export and understand diverse regional demands. This can facilitate smoother transactions and ensure that your requirements are effectively communicated and met.

When considering the best materials for checkered coils, carbon steel stands out for its unique advantages over alternatives such as aluminum and stainless steel. According to the World Steel Association, carbon steel represents approximately 90% of global steel production, attributed to its superior strength-to-weight ratio and cost-effectiveness. This makes carbon steel checkered coils an ideal choice for industries requiring durable flooring solutions, particularly in heavy-duty applications like construction and transportation.

In comparison, stainless steel, while offering excellent corrosion resistance, tends to be significantly more expensive, which can be a limitation for budget-conscious buyers. A report from Market Research Future highlights that the price of stainless steel has been growing steadily, with projections indicating a 5% increase annually over the next five years due to rising production costs. On the other hand, the ease of manufacturing and versatility of carbon steel allows for a more economical solution without compromising quality, making it a preferred choice for a variety of global buyers looking to optimize their material selection.

The carbon steel checkered coil market has been experiencing significant growth, driven by several key factors that cater to both infrastructure demands and industrial applications. One of the primary factors is the ongoing global urbanization, which requires durable and cost-effective materials for construction. Carbon steel checkered coils are favored for their robust properties, making them ideal for flooring, ramps, and various architectural elements. As more countries invest in infrastructure projects, the demand for these high-quality materials continues to rise.

Moreover, technological advancements in manufacturing processes have enhanced the quality and efficiency of producing carbon steel checkered coils. This trend not only ensures consistency in product specifications but also meets the stringent quality standards expected by global buyers. Additionally, the increasing emphasis on sustainability in the steel industry is driving manufacturers to adopt eco-friendly practices, further fueling the demand for high-quality carbon steel products. As companies strive to meet both performance and environmental standards, the future of carbon steel checkered coils looks promising, positioning them as a vital component of modern construction and manufacturing industries.

China's manufacturing sector has long been recognized for its commitment to quality, especially in the realm of carbon steel products. When it comes to carbon steel checkered coils, global buyers can be assured that strict quality standards and certifications are in place. These standards not only ensure the durability and reliability of the products but also align with international benchmarks for safety and environmental sustainability.

Recently, there's been an emerging trend towards emphasizing sustainability within the industry, paralleling developments in other sectors. For example, the introduction of high-integrity standards for low-carbon steel certificates sets a new precedent in ensuring that products meet environmental expectations without compromising quality. Such initiatives point towards a future where carbon steel production incorporates both advanced quality management systems and eco-friendly practices, reflecting a broader recognition of the industry's responsibility towards decarbonization and environmental stewardship. With continuous advancements, industries can expect to see carbon steel products that not only meet rigorous quality standards but also contribute positively to the global green transition.

| Product Type | Thickness (mm) | Width (mm) | Standard | Certification | Application |

|---|---|---|---|---|---|

| Carbon Steel Checkered Coil | 3.0 | 1000 | ASTM A1011 | ISO 9001 | Flooring, Ramps |

| Carbon Steel Checkered Coil | 4.0 | 1250 | JIS G3131 | CE Certification | Heavy Machinery, Truck Beds |

| Carbon Steel Checkered Coil | 5.0 | 1500 | GB/T 700 | SGS Certification | Public Flooring, Stairs |