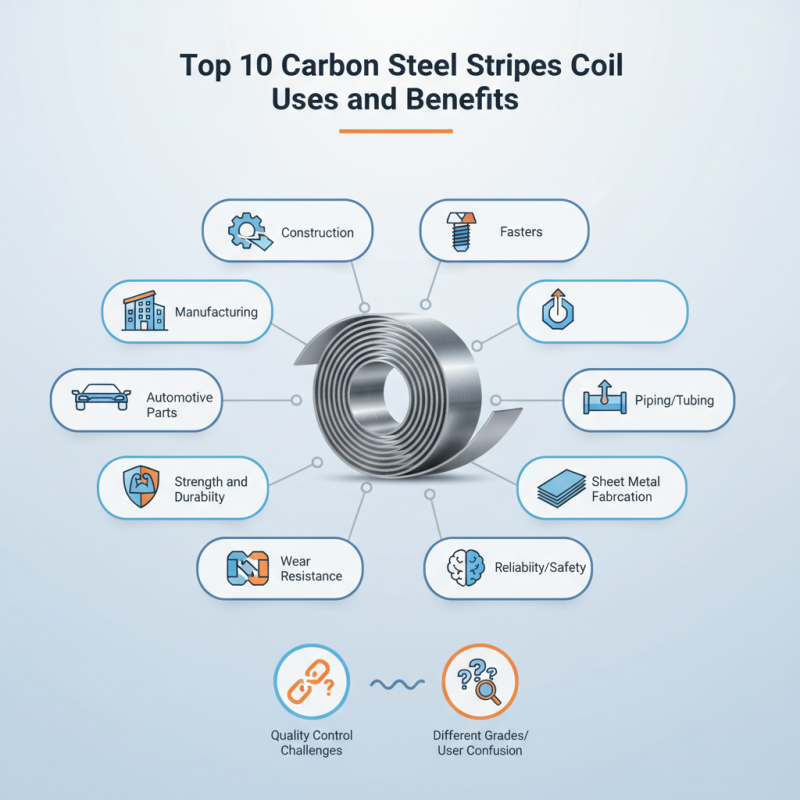

Carbon Steel Stripes Coil is a versatile material. Its unique properties offer numerous benefits across various industries. From construction to manufacturing, this coil serves essential roles.

In construction, Carbon Steel Stripes Coil provides strength and durability. Its resistance to wear makes it ideal for heavy-duty applications. Automotive industries utilize this coil for robust parts. This leads to safer, reliable vehicles.

However, challenges exist. Quality control can sometimes be inconsistent. Additionally, different grades may confuse users. Users must understand their specific needs to select the right type. This knowledge is crucial to maximize the benefits of Carbon Steel Stripes Coil.

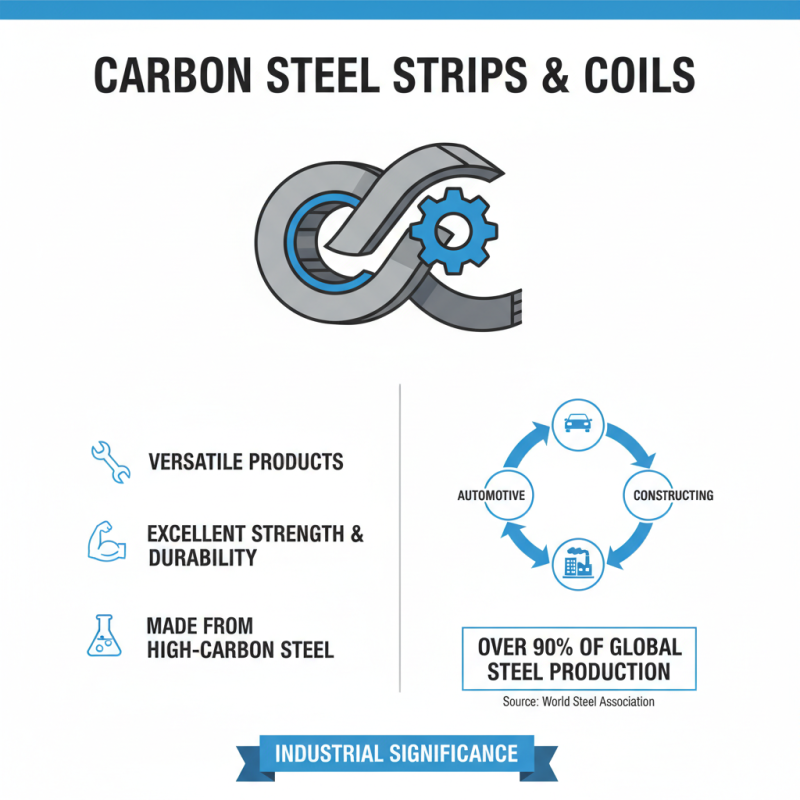

Carbon steel strips coils are versatile products widely used across various industries. They are made from high-carbon steel, providing excellent strength and durability. These coils find applications in automotive, construction, and manufacturing sectors. According to the World Steel Association, carbon steel accounts for over 90% of global steel production. This figure highlights its significance in industrial uses.

One common use of carbon steel strips is in the automotive industry for producing components like springs and brackets. These parts require high tensile strength and flexibility. In construction, carbon steel strips are crucial for reinforcing structures. A report by the National Institute of Standards and Technology indicates that using carbon steel in construction can enhance structural integrity dramatically. However, its susceptibility to corrosion can pose challenges. Proper coating and treatment methods are essential to ensure longevity and performance.

Moreover, carbon steel strips are also prevalent in the manufacturing of appliances and electronics. They are used for cases, frames, and supports due to their strength-to-weight ratio. Despite their advantages, sourcing high-quality steel remains a concern. In some regions, production inconsistencies can affect final product quality. It's essential for manufacturers to invest in robust quality control measures. These complexities highlight areas that need reflection and improvement in production processes.

Carbon steel stripes coil holds a vital role in various industries. Its strength and durability make it a preferred choice for applications requiring robustness. Often employed in construction, these coils are utilized for beams, columns, and reinforcements. The material can withstand heavy loads while maintaining structural integrity.

In manufacturing, carbon steel strips are essential for creating components. Automotive parts, such as springs and brackets, benefit from their resilient nature. Furthermore, the coils are used in packaging and shipping. They offer reliable protection for fragile items. Additionally, their versatility allows for customization in thickness and width, catering to specific project requirements.

Despite their many advantages, one must cautiously consider potential drawbacks. While carbon steel is resistant, it can corrode under certain conditions. Proper treatment and maintenance are vital for longevity. Issues may arise during fabrication if the right processes are not followed. Evaluating the needs of a project can help avoid costly mistakes and improve overall efficacy.

This chart illustrates the top 10 applications of carbon steel stripes coil and their respective usage percentages in various industries. Carbon steel is versatile and widely used due to its strength and durability.

Carbon steel strips are increasingly popular in various industries. They offer unique benefits that can enhance product performance. One of the standout advantages is their strength. These strips can withstand heavy loads, making them ideal for structural applications. Their durability also reduces maintenance costs over time.

One notable detail is their versatility. Carbon steel strips are used in automotive, construction, and many other fields. They can be easily shaped and manipulated to fit specific requirements. This adaptability makes them indispensable in modern manufacturing.

However, one challenge is their susceptibility to rust without proper treatment. Using a protective coating can mitigate this issue.

Another benefit is cost-effectiveness. Compared to other materials, carbon steel strips can be more affordable. This can lead to significant savings on large-scale projects. However, it’s crucial to consider sourcing quality materials. Not all carbon steel is created equal.

Evaluating vendor reliability is essential to ensure longevity and performance. These considerations highlight the importance of informed decision-making in the industry.

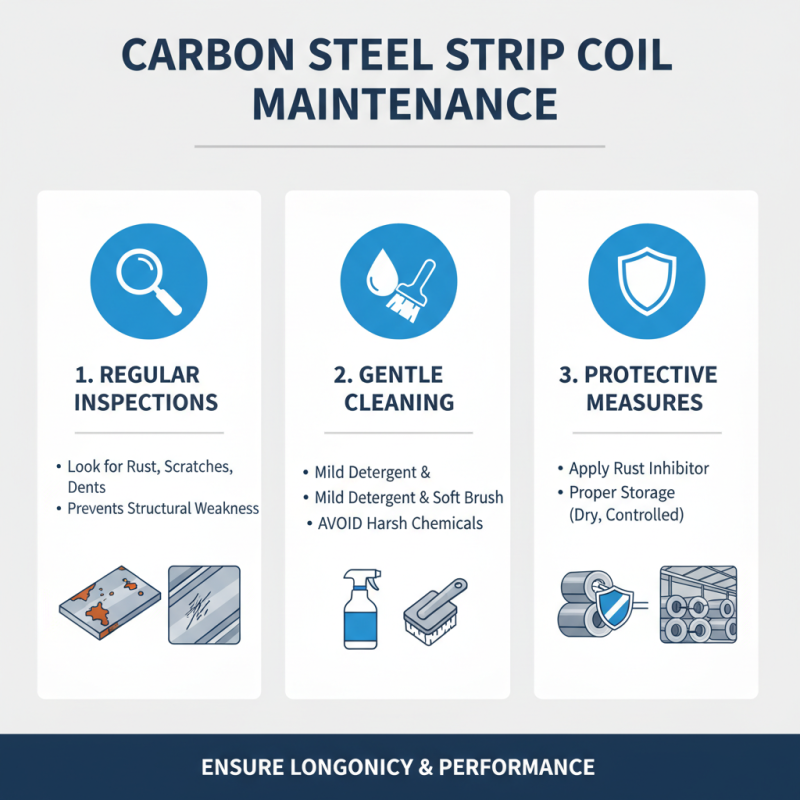

Carbon steel stripes coils require careful maintenance to ensure longevity. Regular inspections are key. Look for signs of rust, scratches, or dents. Issues like rust can weaken the structural integrity. Clean the coils using a mild detergent and a soft brush. Avoid harsh chemicals, as they may cause more harm than good.

Storage is just as important. Keep coils in a dry place. Excess moisture can lead to corrosion. Using protective coatings can offer an additional layer of defense. It’s essential to avoid stacking heavy materials on them. This can cause deformation.

Over time, even with care, some imperfections may occur. Don't ignore them. Addressing minor issues early can prevent larger problems. Remember, a little maintenance can go a long way. Regular attention is vital for optimal performance.

The future of carbon steel stripes coil usage is promising and multifaceted. As industries evolve, so do the applications of these materials. In construction, for example, lighter and stronger coils are becoming essential. They reduce building weight while maintaining integrity. The trend toward sustainability also influences this market. Companies aim to minimize waste and enhance recycling methods through the innovative use of carbon steel.

Tips: Consider using a coil that combines strength with pliability. This balance can enhance performance in various applications.

Another emerging trend is the integration of technology in production. Smart manufacturing processes are improving efficiency and quality. While this may lead to higher initial costs, the long-term benefits are significant. Thus, it’s crucial to assess both immediate expenses and future savings.

Tips: Regularly evaluate the performance of the coils you use. This can reveal opportunities for cost savings. There is much potential in exploring these evolving technologies, yet reflection on the environmental impact is essential.