In the world of manufacturing, the significance of materials cannot be overstated, and one material that has emerged as a vital component across various industries is the Carbon Steel Strip Coil. Renowned industry expert Dr. Emily Johnson emphasizes its importance, stating, "The versatility and strength of Carbon Steel Strip Coil make it an indispensable resource in modern manufacturing processes." This notable product, made from a combination of iron and carbon, showcases exceptional durability and flexibility, making it ideal for a wide range of applications, from automotive components to electrical equipment.

Understanding the properties and applications of Carbon Steel Strip Coil is crucial for manufacturers aiming to enhance their production efficiency and cost-effectiveness. Due to its ability to be easily shaped and formed, carbon steel strip coils are increasingly being utilized in the creation of high-strength and lightweight products. As industries evolve with the shift towards more sustainable practices, the relevance of this material continues to grow, paving the way for innovative applications that not only meet market demands but also contribute to a more eco-friendly manufacturing landscape. By delving into the characteristics and uses of Carbon Steel Strip Coil, manufacturers can unlock new possibilities for their production strategies in the competitive market.

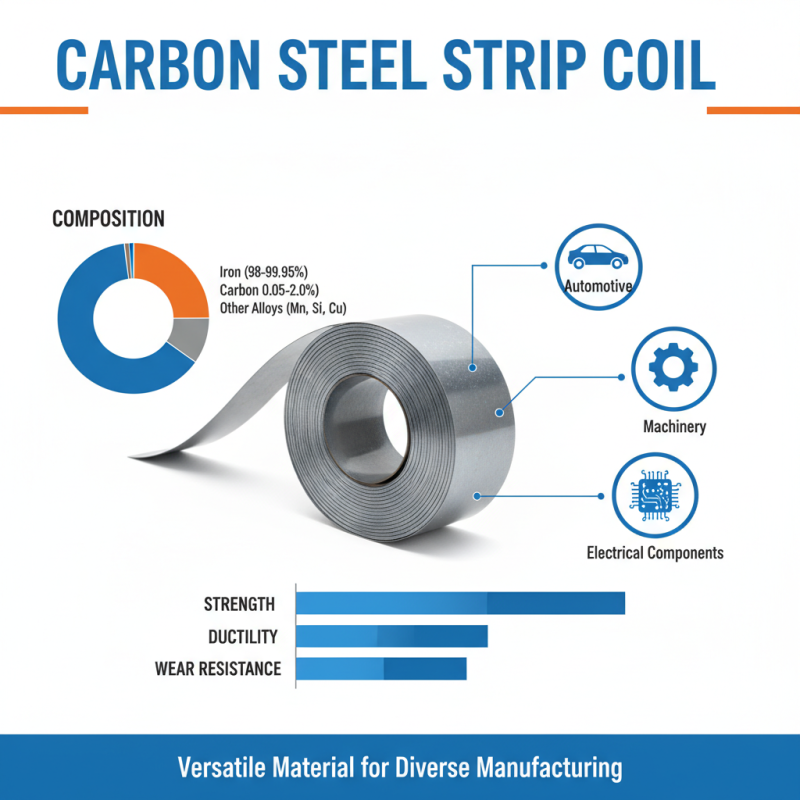

Carbon steel strip coil is a versatile material widely used in various manufacturing processes due to its unique properties and composition. Defined primarily by its iron content, carbon steel typically comprises 0.05% to 2.0% carbon, in addition to other alloying elements such as manganese, silicon, and copper. This specific composition allows for a balance of strength, ductility, and wear resistance, making it an ideal choice for applications ranging from automotive components to electrical steel sheets.

The production process of carbon steel strip coil usually involves hot or cold rolling techniques, resulting in a thinner profile that enhances its suitability for precision applications. According to industry reports, the demand for carbon steel in strip coil form is projected to grow at a compound annual growth rate (CAGR) of around 4.5% through 2025, primarily driven by its increasing utilization in the automotive and construction sectors. Additionally, the flexible nature of carbon steel makes it an excellent candidate for stamping, forming, and welding processes, providing manufacturers with enhanced efficiency and cost-effectiveness.

Tips: When selecting carbon steel strip coil for your manufacturing needs, consider factors such as tensile strength, elongation, and yield strength to ensure the material meets your specific requirements. Additionally, proper storage and handling of the coils can minimize the risk of surface damage, preserving the quality for optimal machining processes.

Carbon steel strip coils are integral to various manufacturing processes due to their versatility, durability, and cost-effectiveness. These coils are used extensively in industries such as automotive, construction, and appliances. According to a report by the World Steel Association, the demand for carbon steel products, including strip coils, is expected to reach approximately 1.7 billion tons by 2025. This highlights a growing reliance on carbon steel in manufacturing, particularly for components that require high strength and formability.

In manufacturing, carbon steel strip coils undergo several processes such as blanking, stamping, and bending, which allow for the efficient production of parts tailored to specific applications. The American Iron and Steel Institute notes that nearly 45% of all carbon steel is used in the automotive sector, where precision and reliability are critical. The ability to produce automotive components from carbon steel strip coils not only enhances performance but also meets stringent safety standards, making it a vital material in vehicle production. Additionally, as industries pursue various sustainability initiatives, the production of carbon steel strip coils using advanced techniques such as electric arc furnace technology is on the rise, which further minimizes the environmental impact while maintaining high-quality output.

Carbon steel strip coil is a crucial material in the manufacturing industry, known for its versatility and strength. This product is characterized by a high carbon content, typically ranging from 0.05% to 2.0%, which enhances its hardness and strength, making it suitable for various applications such as automotive parts, construction materials, and machinery components. According to the World Steel Association, carbon steel accounts for over 90% of total steel production globally, underlining its significance in industrial use.

One of the key properties of carbon steel strip coil is its excellent formability and weldability, allowing manufacturers to easily shape and join materials to meet specific requirements. The coil's mechanical properties, such as tensile strength, yield strength, and ductility, can be optimized through heat treatment and alloying, making it adaptable for different manufacturing processes. Additionally, carbon steel strip coil offers good wear resistance, which is essential in high-performance environments. Studies indicate that the average tensile strength of carbon steel strip can reach up to 600 MPa, making it a reliable choice for durable applications.

Tips: When selecting a carbon steel strip coil for your project, consider the specific mechanical properties required for your application. Utilizing advanced testing methods can ensure that the steel meets the necessary specifications. Additionally, always assess the environmental impact of your choice, as carbon steel can be recycled, contributing to sustainable manufacturing practices.

This bar chart illustrates the key properties of Carbon Steel Strip Coil, displaying values like carbon content, tensile strength, yield strength, elongation, and hardness, which are essential for understanding its applications in manufacturing.

Carbon steel strip coils are widely utilized in various industries due to their excellent strength, durability, and versatility. One of the most common applications of these coils is in the manufacturing of automotive components. They are used to produce parts such as brackets, clips, and structural components that require high tensile strength and resistance to wear. The ability of carbon steel strip coils to be formed, welded, and machined makes them ideal for the automotive industry, where precision and reliability are critical.

Another significant application of carbon steel strip coils can be found in the construction industry. These coils are often used in the fabrication of steel frames, structural support beams, and various types of reinforcements. The inherent properties of carbon steel, such as its ability to withstand heavy loads and external stressors, make it a preferred material for building infrastructure like bridges and high-rise buildings. Additionally, carbon steel strips can be processed into various shapes and sizes, allowing for custom solutions tailored to specific construction needs, further enhancing their adaptability in industrial applications.

Carbon steel strip coil is a versatile material widely used in various manufacturing applications due to its unique properties and advantages. One of the primary benefits of carbon steel strip coil is its high strength-to-weight ratio, which allows manufacturers to create robust products without adding excessive weight. This makes it an ideal choice for industries such as automotive and construction, where lightweight materials can enhance performance and efficiency.

Another significant advantage of carbon steel strip coil is its excellent malleability and formability. This characteristic enables manufacturers to easily shape and customize the material into a wide range of products, such as brackets, springs, and various precision parts. Additionally, carbon steel can be heat-treated to improve its hardness and wear resistance, further expanding its applications in manufacturing environments where durability is crucial.

Moreover, carbon steel strip coil is relatively cost-effective compared to other materials, making it a popular choice for high-volume production runs. Its availability in various grades allows manufacturers to select the most suitable option for their specific requirements, ensuring both quality and economy in their production processes. Overall, the advantages of carbon steel strip coil significantly contribute to its wide adoption in diverse sectors of manufacturing, enhancing efficiency and product performance.