In the modern manufacturing landscape, the use of Carbon Steel Sheet Coil is becoming increasingly prevalent. According to industry reports, the global carbon steel market is projected to reach over $1 trillion by 2026. This growth is fueled by the material's exceptional strength and versatility. Carbon Steel Sheet Coil is widely recognized for its applications in industries ranging from automotive to construction.

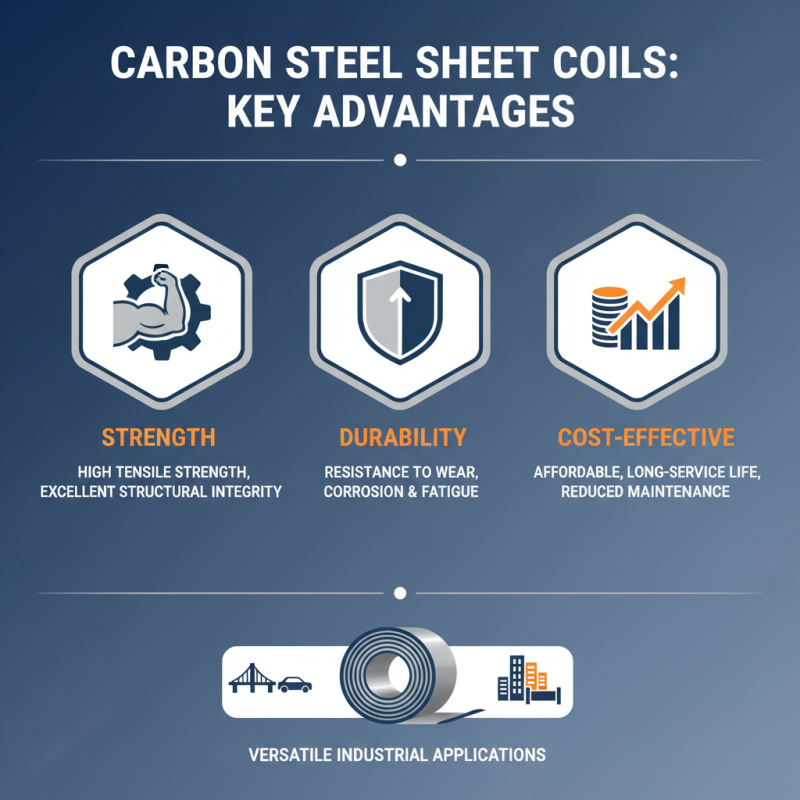

The benefits of Carbon Steel Sheet Coil are notable. It offers excellent weldability and formability, making it ideal for various fabrication processes. Its durability ensures long-lasting performance in harsh environments. Reports indicate a significant rise in demand for carbon steel products due to their cost-effectiveness. However, challenges like susceptibility to rust may require protective coatings, highlighting areas for improvement in material management.

As industries innovate and adapt, Carbon Steel Sheet Coil remains a fundamental choice. Its role in structural components and industrial applications cannot be overstated. Ensuring quality and sustainability in usage is essential. The future of this material will depend on addressing these challenges while leveraging its strengths.

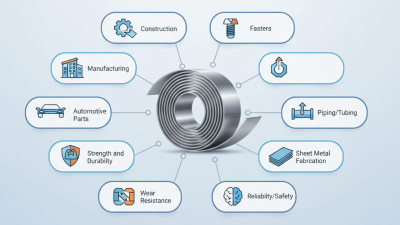

Carbon steel sheet coils are essential in various industries. They are made from a combination of iron and carbon, offering strength and durability. This material is widely used for manufacturing products like auto parts, appliances, and construction materials. Its versatility makes it a favorite among builders and manufacturers.

One significant advantage of carbon steel sheet coils is their ability to withstand heavy loads. They are tough and can handle considerable pressure without deforming. However, this strength comes with a challenge. Carbon steel can be prone to rust and corrosion if not properly coated or maintained. Regular checks and maintenance are essential to prolong its lifespan.

Another aspect to consider is the aesthetic appeal. While carbon steel has a raw, industrial look, it can be treated or painted to suit different applications. Still, achieving the desired finish can be tricky. The balance between functionality and aesthetics requires careful planning and execution. Understanding these factors is crucial for those who work with carbon steel sheet coils.

Carbon steel sheet coils are known for their strength and versatility. These materials contain iron and a small percentage of carbon, making them suitable for various applications. A key characteristic is their excellent tensile strength, often exceeding 400 megapascals. This makes them ideal for construction and manufacturing sectors.

In industries, carbon steel exhibits notable ductility which allows it to be formed into complex shapes. However, one must remember that while it’s prone to corrosion, applying protective coatings can mitigate this issue significantly. Reports indicate that over 50% of carbon steel's usage is in construction. This includes beams, columns, and reinforcement bars.

Tips: Ensure you're aware of the carbon content in the steel you choose. Higher carbon levels increase hardness but can reduce ductility. Always factor in the environment of use, as weather can affect longevity. Regular inspection is crucial to avoid unexpected failures. Carbon steel's contribution to sectors is significant, yet some may overlook its limitations in harsh environments. Understanding these properties can lead to better material choices.

Carbon steel sheet coils are widely used across various industries. They offer excellent durability and strength. Common applications include construction, automotive, and manufacturing. In construction, these coils serve as structural components. They form beams, columns, and frames. Their ability to withstand heavy loads makes them ideal for these purposes.

In the automotive industry, carbon steel sheet coils are essential. They are used to produce body panels and other parts. Their malleability allows for intricate designs. However, some may struggle with corrosion if not properly coated. This is a point for manufacturers to consider.

Manufacturing also benefits from these coils. They are used to create appliances, machinery, and tools. Their versatility is a strong advantage. Yet, oversights in quality control can lead to defects. This is an area that requires ongoing improvement. Exploring these applications shows the potential of carbon steel sheet coils.

Carbon steel sheet coils are essential in various industries. They offer significant advantages that make them a popular choice. One of the main benefits is their strength. Carbon steel has a high tensile strength, providing excellent structural integrity. This strength is crucial for manufacturing components that need to withstand heavy loads.

Another advantage is their flexibility in applications. These coils can be easily shaped, cut, and welded into different forms. This versatility makes them suitable for automotive parts, construction materials, and appliances. Additionally, carbon steel has good corrosion resistance when properly coated, extending its lifespan.

Despite these benefits, there are challenges. The production process can lead to inconsistencies in quality. Sometimes, imperfections occur, affecting durability. Moreover, improper handling may cause damage. Users must ensure they manage the coils with care to maximize their benefits. Regular inspections are necessary to avoid using flawed materials.

Maintaining carbon steel sheet coils requires attention and care. Storage is crucial. Keep them in a dry, clean area to prevent rust. Humidity can lead to corrosion, so check conditions regularly. A well-ventilated space is essential. Always elevate coils off the ground to avoid moisture accumulation.

Cleaning is another key aspect. Use a mild detergent and water for routine cleaning. Avoid abrasive scrubbing pads that can scratch the surface. After cleaning, ensure they are thoroughly dried. Apply a light oil coating if the surface appears dull. This helps protect against oxidation, but don't overdo it. Too much oil could attract dirt.

Inspection plays an important role too. Regular checks can reveal minor issues before they become major problems. Look for signs of rust or wear. If any damage is found, address it promptly. Ignoring small issues can lead to costly repairs down the road. Developing a maintenance routine can enhance the longevity and performance of the coils. Seeking feedback from experienced users can refine best practices.