As we move toward 2025, the significance of Carbon Steel Coil Hot Rolled materials in various industries is becoming increasingly evident. These versatile materials play a critical role in construction, automotive, and manufacturing sectors, where their strength and adaptability are unparalleled. With the ongoing advancements in technology and sustainable practices, the applications of hot rolled carbon steel coil are set to evolve, reflecting changes in market demands and environmental considerations.

The trends in Carbon Steel Coil Hot Rolled applications are influenced by a combination of factors, including growing urbanization, the rise of renewable energy projects, and innovations in production techniques. Manufacturers are now focusing on enhancing product performance while reducing the environmental footprint, ensuring that these materials not only meet the current market needs but also contribute to a sustainable future. As we explore the top trends expected in 2025, it is crucial to understand how these developments will shape industries and influence the overall economy. The insights gleaned from these trends will be invaluable for stakeholders looking to navigate the changing landscape of carbon steel applications effectively.

The automotive industry is witnessing a significant shift towards the increased use of hot rolled carbon steel coils, largely driven by advancements in manufacturing techniques and a focus on sustainability. According to a recent report from the World Steel Association, the global automotive steel market is expected to surpass $200 billion by 2025, with hot rolled steel representing a crucial sector due to its versatility and strength. This material is becoming increasingly favored for various components, including chassis, body panels, and structural parts, owing to its ability to be easily shaped and welded while maintaining high structural integrity.

One major trend emerging within automotive applications is the integration of lightweight designs. Hot rolled carbon steel coils provide an excellent balance of strength and weight, contributing to the overall fuel efficiency of vehicles. As governments worldwide implement stricter emission regulations, manufacturers are investing in new technologies, such as advanced high-strength steel (AHSS), derived from hot rolled carbon steel, to meet these standards. Furthermore, the rise of electric vehicles (EVs) is also spurring demand for efficient, durable, and cost-effective materials, solidifying hot rolled carbon steel's role in the future of automotive production. Reports indicate that by 2025, hot rolled carbon steel could account for over 30% of materials used in EV manufacturing, reflecting the adaptability and crucial nature of this material in evolving automotive designs.

| Application Area | Estimated Growth Rate (%) | Key Features | Advantages |

|---|---|---|---|

| Automotive Body Components | 10% | High durability, lightweight | Improved fuel efficiency |

| Chassis and Frames | 8% | Enhanced strength, customizable | Increased vehicle safety |

| Engine Components | 12% | Heat resistant, high tensile properties | Enhanced performance and longevity |

| Suspension Parts | 9% | Flexible and robust | Enhanced driving comfort |

| Exhaust Systems | 11% | Corrosion resistant, lightweight | Reduced emissions and improved efficiency |

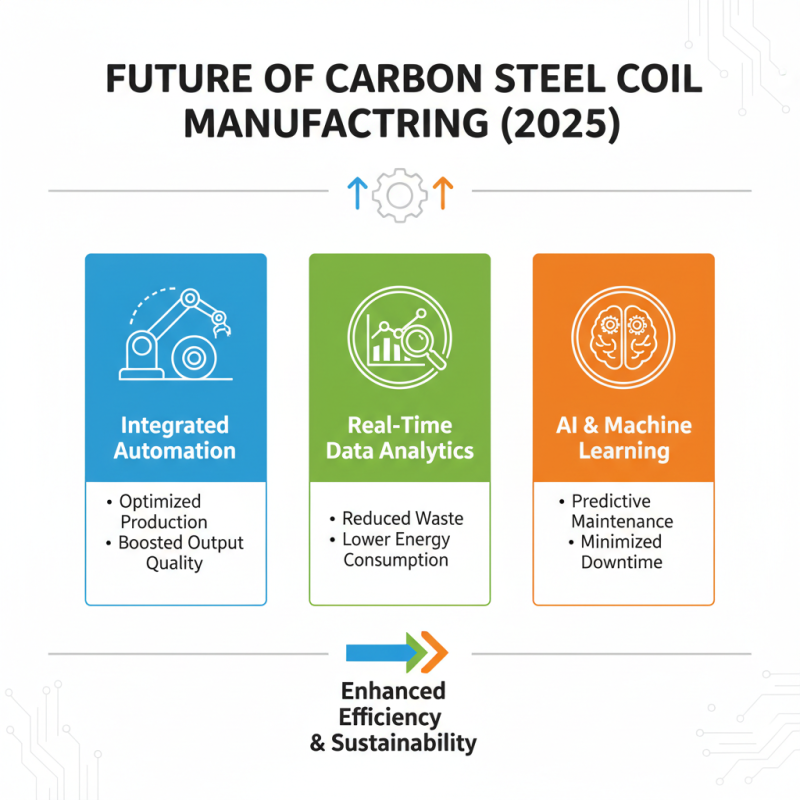

In the pursuit of enhanced efficiency and sustainability, advancements in manufacturing techniques for carbon steel coil products are set to reshape the industry landscape by 2025. State-of-the-art technologies, such as integrated automation and real-time data analytics, empower manufacturers to optimize production processes. These innovations not only boost output quality but also significantly reduce waste and energy consumption. The adoption of artificial intelligence and machine learning algorithms in predictive maintenance allows for timely interventions, minimizing downtime and enhancing overall productivity.

Moreover, the implementation of advanced metallurgy in producing hot-rolled carbon steel coils is paving the way for stronger and more durable products. Techniques such as microstructural engineering enable manufacturers to tailor the properties of steel, resulting in materials that can withstand increased loads and environmental stressors. As manufacturers push the envelope with innovative heat treatment and surface finishing processes, the performance of carbon steel coils is reaching unprecedented levels, benefitting sectors ranging from construction to automotive. These advancements underline a collective industry commitment to meeting the evolving demands of consumers while aligning with sustainability goals.

As the world steers towards more sustainable practices, the impact of environmental regulations on carbon steel coil production is becoming increasingly significant. In 2025, businesses in the steel industry will face stricter compliance requirements aimed at reducing greenhouse gas emissions and minimizing resource consumption. These regulations are designed to encourage the implementation of cleaner production technologies, which can involve higher upfront costs but ultimately result in a greener footprint for producers. This shift not only affects the manufacturing processes but also influences the supply chain, pushing manufacturers to adopt more sustainable raw materials and energy sources.

Additionally, the emphasis on environmental accountability is driving innovation within the industry. Companies are investing in research and development to enhance energy efficiency and waste management in the production of hot-rolled carbon steel coils. Advanced techniques such as recycling scrap steel and utilizing renewable energy sources can significantly lower emissions while also adhering to new regulatory standards. As these changes take place, it's likely that there will be a competitive advantage for businesses that proactively adapt to these environmental guidelines, setting a benchmark for others in the sector to follow.

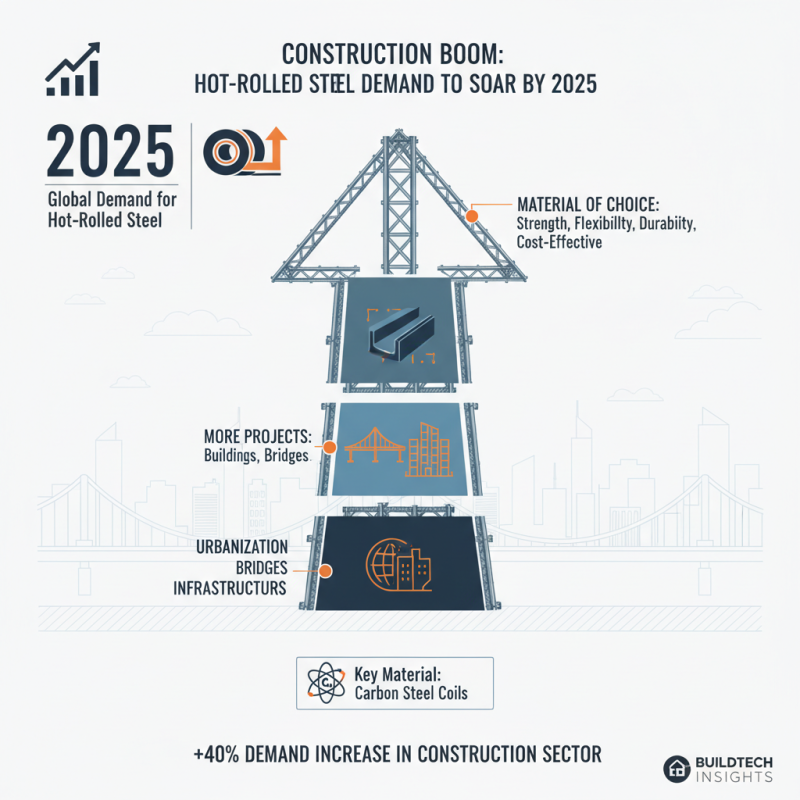

The construction sector is poised for substantial growth in the demand for hot rolled steel, particularly carbon steel coils, by 2025. As urbanization accelerates globally, infrastructure projects are on the rise, leading to an increased need for materials that provide strength and flexibility. Hot rolled steel, renowned for its durability and cost-effectiveness, is becoming the material of choice for various structural applications, including beams, columns, and reinforcements in buildings and bridges.

As this demand grows, companies in the construction industry should focus on optimizing their supply chains to ensure timely access to high-quality materials. Proactive planning will be essential to mitigate delays and manage costs effectively.

Tips: When sourcing hot rolled steel, consider factors like thickness, width, and surface condition to align with project specifications. Moreover, maintaining strong relationships with suppliers can help secure better pricing and availability, making a significant impact on project timelines and budgets.

Additionally, integrating sustainability practices into the procurement of steel can enhance not only the environmental footprint but also appeal to clients focused on green building initiatives. As demand for eco-friendly construction increases, choosing suppliers who prioritize sustainable production methods can set a project apart in a competitive market.

In 2025, the landscape of carbon steel coil hot rolled applications will be significantly shaped by technological innovations that enhance processing efficiency. Advances in automation, particularly the integration of Industry 4.0 technologies such as IoT (Internet of Things) and AI (Artificial Intelligence), are set to revolutionize production capabilities. According to a recent industry report, automating data collection and monitoring processes can increase operational efficiency by up to 30%, optimizing resource allocation and minimizing waste during production.

Moreover, innovations in processing techniques, such as advanced rolling methods and improved heat treatments, are likely to provide better material properties and surface finishes. These enhancements not only lead to increased durability and mechanical performance of carbon steel coils but also help in reducing energy consumption. A study by the Steel Institute indicates that modern processing technologies have the potential to decrease energy use in hot rolling by as much as 15% compared to traditional methods. These advancements are crucial, as they address the growing demand for sustainable practices within the industry while supporting manufacturers in maintaining competitive pricing.

The focus on real-time analytics and predictive maintenance systems will further bolster efficiency in carbon steel coil processing. By leveraging data insights, manufacturers can anticipate equipment failures and streamline maintenance schedules, which is projected to reduce downtime by approximately 20%. As the industry approaches 2025, these technological innovations will undoubtedly pave the way for more efficient and sustainable practices, positioning carbon steel coils as a vital component in various applications, from automotive to construction.

This chart illustrates the projected growth of various applications of hot rolled carbon steel coils by 2025. The data highlights the increasing demand across different industries that are adopting innovative processing technologies to enhance efficiency.