In today's manufacturing landscape, "Carbon Steel Coil Cold Roll" has emerged as a vital component in various applications. John Smith, a leading expert in the steel industry, once stated, "Cold rolled carbon steel coils are the backbone of modern fabrication." This highlights the importance of understanding its specific uses and advantages.

Carbon steel coils processed through cold rolling offer unmatched precision and finish. Industries ranging from automotive to appliances rely on this material for its extraordinary strength and versatility. The manufacturing process enhances the steel's properties, making it a favored choice among engineers.

However, there are challenges within this industry. Not every application may benefit from carbon steel coil cold roll. For instance, the cost might be higher compared to other materials. It is essential to weigh the benefits against the drawbacks. Companies need to assess if cold rolled variations are suitable for their projects. Balancing quality and cost can be a tricky endeavor.

The carbon steel coil cold rolling process is essential in manufacturing. It involves reducing the thickness of steel sheets through mechanical pressure at room temperature. This method enhances the material's strength and improves surface finish. Thick steel strips are rolled into thinner sheets. These sheets are then used in various applications, such as automotive parts, appliances, and construction materials.

One effective tip is to monitor temperature closely during the process. Too much heat can change the metal's properties, leading to defects. Regularly check the equipment's alignment. Misalignment can cause uneven rolling, resulting in wasted material.

Another consideration is the cleanliness of the steel surfaces. Any contamination can affect adhesion and finish quality. Cleaning the coils before rolling prevents additional costs. Always question if your processes can improve. Even small adjustments might lead to better efficiency or product quality. This reflection can foster a culture of continuous improvement.

Cold rolled carbon steel coils are widely used in various industries due to their unique properties. They are known for their high strength and excellent surface finish. According to industry reports, the cold rolling process can improve the yield strength of steel by up to 25%. This makes them ideal for applications where durability is crucial.

One major application is in the automotive industry. Cold rolled steel is used in the manufacturing of car body panels. These panels require both strength and aesthetic appeal, which cold rolled steel provides. The automotive sector accounts for nearly 60% of cold rolled carbon steel production. Additionally, this type of steel is commonly found in appliances, such as refrigerators and washing machines. The sleek finish enhances product design while ensuring reliability.

However, there are challenges. Cold rolled strips can be more prone to cracking under certain stresses. This often occurs during bending processes. Manufacturers must carefully monitor production processes to mitigate such issues. Regular quality checks can help ensure product integrity. The industry must continue to innovate to overcome limitations and enhance the performance of cold rolled carbon steel.

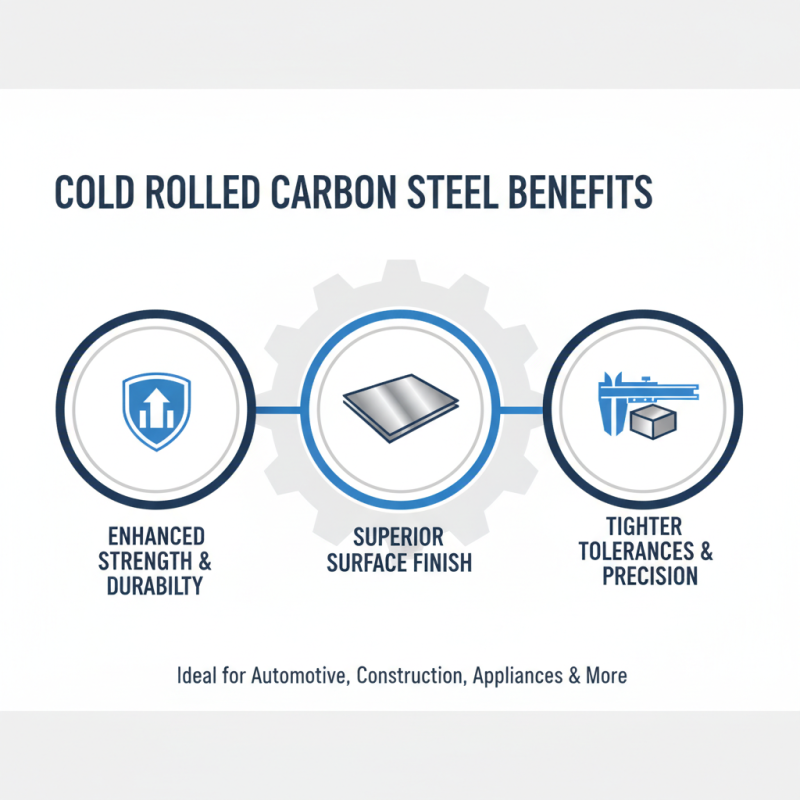

Cold rolled carbon steel offers several appealing benefits for manufacturers. Its enhanced strength and durability make it a preferred choice in various industries. This type of steel undergoes significant processing, which results in a finer surface finish and tighter tolerances. The smooth surface is ideal for applications where aesthetics and precision matter.

Another advantage is its versatility. Cold rolled steel can be easily shaped and formed into complex designs. This flexibility opens up a wide range of applications, from automotive components to home appliances. However, manufacturers must consider that the production process can lead to some brittleness. This aspect may affect its performance under certain conditions.

Cost-effectiveness is another key point. Although initial expenses may be higher, the long-term benefits often outweigh the costs. Cold rolled carbon steel provides better yield strength, reducing the need for thicker materials. This can lead to savings in both material and labor. Nonetheless, attention should be given to its limitations. Proper handling and processing are essential to maximize its advantages.

When comparing cold rolled and hot rolled carbon steel coils, the differences in their manufacturing processes play a crucial role. Cold rolled steel is processed at room temperature, making it stronger and more durable. The surface finish is smooth and has a more precise dimension compared to its hot rolled counterpart. This precision is vital for applications that require tight tolerances, like hydraulic cylinders and structural components.

Hot rolled steel, on the other hand, is made by processing at high temperatures. It is more malleable and easier to form into various shapes. However, the finish tends to be rougher, which might not be suitable where aesthetics are important. The process can introduce scale, which needs to be removed for certain uses. These characteristics make hot rolled steel a preferred choice for general fabrication where precise tolerances are not required.

In practicality, choosing between these options comes with trade-offs. Cold rolled steel might cost more, and sometimes working with it requires specific machinery. Hot rolled steel can have inconsistencies in thickness and width. Both types have distinct benefits and drawbacks, demanding careful thought depending on the application.

| Application | Benefits | Cold Rolled Features | Hot Rolled Features |

|---|---|---|---|

| Automotive Parts | Enhanced surface finish and precise dimensions | Higher strength and better surface quality | Lower cost and ease of fabrication |

| Electrical Appliances | Good magnetic properties and improved surface finish | Tighter tolerances and consistency | Larger quantities available and lower yield strength |

| Construction Materials | Durability and high strength | Smooth surface and enhanced weldability | Easier to work with in large sections |

| Furniture Manufacturing | Aesthetic appeal and long-lasting products | Improved finish and greater precision | Lower processing costs for bulk materials |

| Kitchen Equipment | Corrosion resistance and hygiene | Clean surface and better strength | Wider size availability and ease of shaping |

The cold rolling of carbon steel coils is evolving rapidly. In recent years, the industry has witnessed significant technological advancements. Innovations in automation and digitalization are becoming more common. According to a recent report by Grand View Research, the global cold rolled steel market is projected to reach $500 billion by 2027, reflecting a hefty annual growth rate.

A notable trend is the integration of AI in quality control. AI systems can detect defects faster than human inspectors. This reduces waste and ensures better quality in products. Furthermore, automation is providing companies with the ability to operate with fewer employees. This raises questions about job security but also highlights efficiency improvements. These innovations are not without challenges.

Sustainability is a growing concern in the cold rolling sector. Companies are striving to reduce energy consumption. Many are investing in cleaner technologies. However, the transition is complex and costly. According to a study by the World Steel Association, the industry must cut its carbon emissions by 30% by 2030. Balancing technological advancement and environmental responsibilities remains a pressing issue.

This bar chart illustrates the rating of different applications for carbon steel coil cold rolling. The ratings reflect the benefits of using carbon steel in various industries, showcasing its importance and versatility in modern technology and manufacturing.