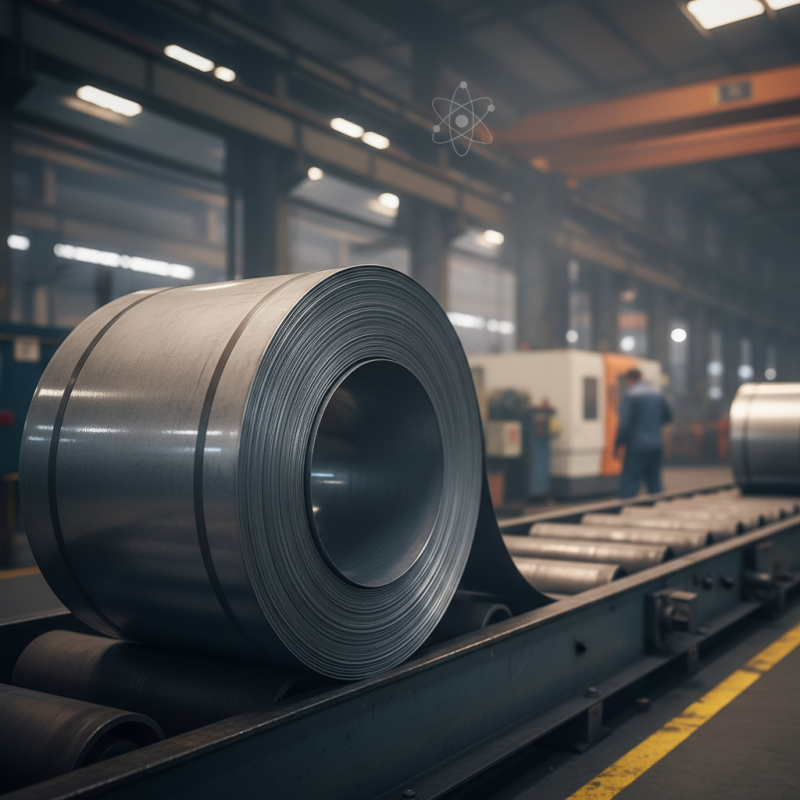

In the world of manufacturing, understanding the applications and benefits of Carbon Steel Coil Stip is critical. Industry expert John Doe states, "Carbon Steel Coil Stip is a backbone in various sectors." This material is versatile, cost-effective, and strong, making it a popular choice for many applications.

Carbon Steel Coil Stip can be found in construction, automotive, and appliance sectors. Its ability to withstand stress while maintaining form is notable. However, despite its benefits, there are areas that require improvement. For example, the susceptibility to corrosion can be a concern. Managing this challenge is crucial for long-term use.

As industries evolve, the demand for innovative solutions increases. Carbon Steel Coil Stip holds great potential but also faces limitations. Reflecting on its benefits and challenges can lead to better practices and enhanced performance. Emphasizing durability while tackling corrosion issues should be a priority for manufacturers.

Carbon steel coil is a versatile material used in various industrial applications. Understanding its specifications is crucial for manufacturers. The typical thickness of carbon steel coils ranges from 0.2 mm to 25 mm, offering flexibility for numerous uses. Widths often span from 600 mm to 2000 mm, depending on processes like rolling and slitting. According to the World Steel Association, demand for carbon steel has surged, with global production reaching over 1.8 billion tons in recent years.

The tensile strength of carbon steel coils makes them an attractive choice in construction and automotive sectors. They exhibit strength levels ranging from 250 MPa to 600 MPa. However, the chemical composition can vary, which affects their performance. For example, higher carbon content results in increased hardness but decreased ductility. Users must carefully evaluate these properties to match their specific needs.

Moreover, corrosion resistance is an essential aspect to consider. Many carbon steel coils require protective coatings to enhance durability. The cost of these treatments can impact overall project budgets, reflecting a need for careful planning. Each application may have different requirements, making it vital to analyze the exact specifications of the material thoroughly. Advances in technology continue to influence production methods, yet inconsistencies in quality remain an industry challenge.

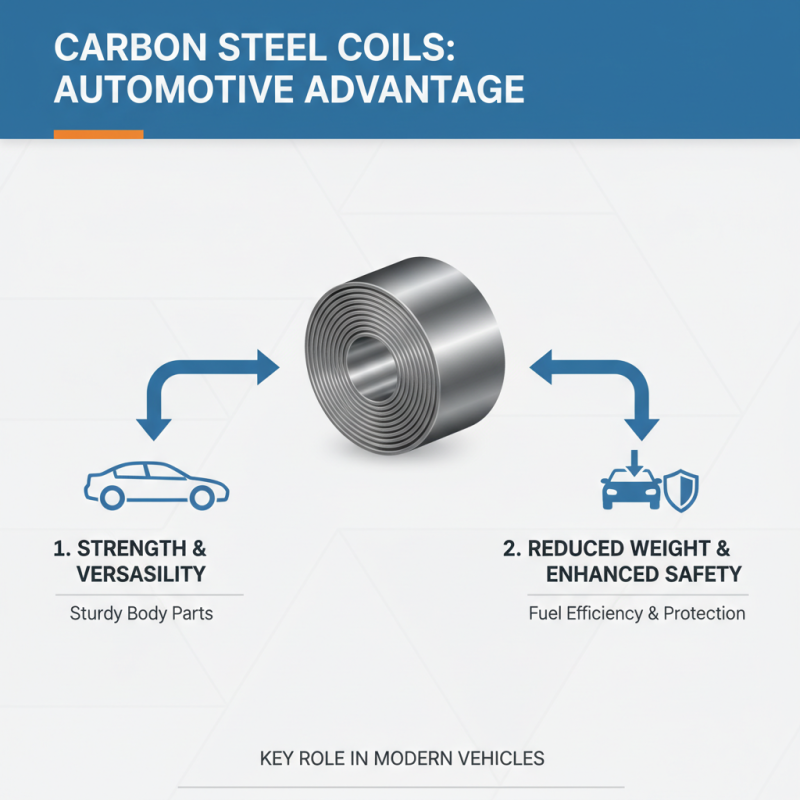

Carbon steel coils play a vital role in various industries. They are known for their strength and versatility. One prominent application is in the automotive sector. Car manufacturers use these coils to produce sturdy body parts. This helps reduce overall vehicle weight while ensuring safety.

In construction, carbon steel coils are commonly employed for making structural components. Beams, sheets, and scaffolding benefit from their durability. However, the risk of corrosion is noteworthy in humid environments. Protective coatings can help, but they add complexity to the process.

Another key area is manufacturing appliances. Carbon steel coils contribute to the production of household items like refrigerators and ovens. Their resilience to high temperatures makes them ideal. Yet, achieving the right balance between cost and quality can be challenging. Industries must continually evaluate these factors to maximize performance.

Carbon steel coils have become a preferred choice in various industries. Their unique attributes set them apart from other materials. For instance, according to a recent market analysis, carbon steel coils account for nearly 30% of the global steel coil market. This popularity stems from several advantages.

One significant benefit is strength. Carbon steel coils exhibit high tensile strength. This feature is crucial in applications requiring durability. They are less prone to deformation under heavy loads compared to aluminum or PVC alternatives. Additionally, their resistance to impact makes them ideal for automotive and construction applications. A study indicates that carbon steel's impact resistance is 20% higher than that of stainless steel, making it a reliable choice.

Another noteworthy advantage is cost-effectiveness. Carbon steel coils are generally less expensive than other materials. In a cost analysis report, carbon steel was found to be 15-20% cheaper than aluminum when used in similar applications. Despite its cost efficiency, there are areas where carbon steel may fall short, such as corrosion resistance. Without proper coating, it can rust, requiring additional maintenance. This aspect must be considered during material selection. Overall, carbon steel coils present compelling advantages that appeal to industries worldwide, despite some challenges.

This chart highlights the key advantages of using carbon steel coils over other materials, including their cost efficiency, durability, and strength to weight ratio. The data reflects the perceived benefits in the industrial application of carbon steel compared to alternatives.

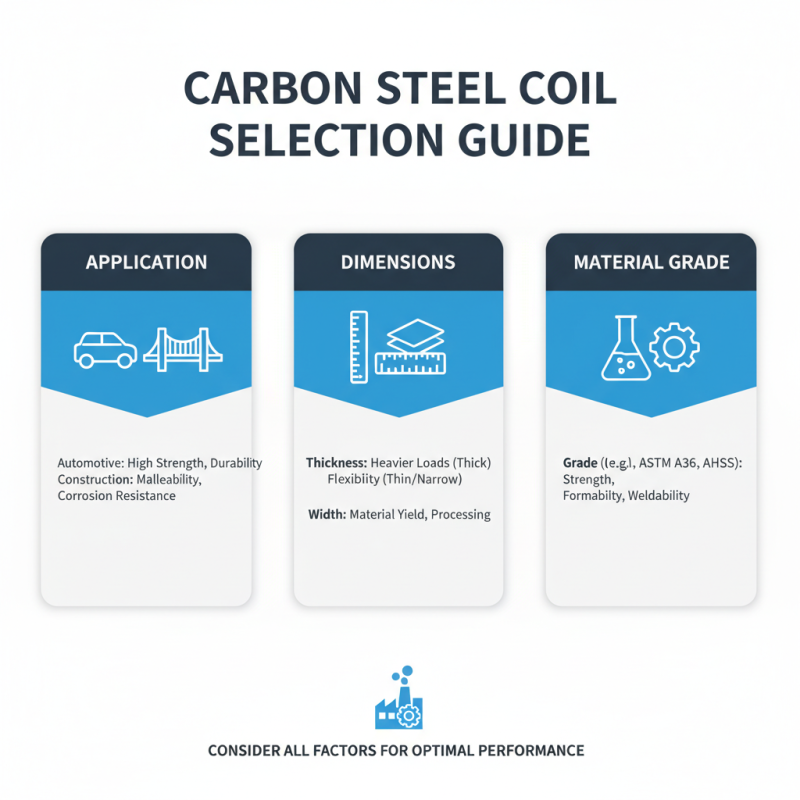

When selecting carbon steel coils, various factors come into play. The intended application is crucial. For instance, automotive parts demand high strength and durability. In contrast, construction materials may prioritize malleability and corrosion resistance. The thickness and width of the coils also matter. A thicker coil can handle heavier loads but may be less flexible.

Environmental considerations are another influencing factor. Areas with high humidity or salinity require more corrosion-resistant options. On the other hand, if environmental conditions are stable, standard carbon steel may suffice. Cost plays a significant role too. While premium options offer advanced features, they may not always fit a budget. It's essential to balance quality and expense wisely.

Lastly, the manufacturing process can impact the coil's performance. The method of production may affect the material's properties, including strength and ductility. Not all processes yield the same results. Sometimes, a less optimized method may fall short in performance. It's crucial to evaluate each step and its impact on the final product.

Maintaining carbon steel coils is crucial for their longevity and performance. Regular inspections help identify wear and damage early. Look for signs of rust, which can lead to serious issues. Proper storage is equally important. Keep coils in a dry, ventilated area to prevent corrosion.

Tips: Use protective coatings when possible to minimize rust. This can extend the life of the coils significantly.

Handling carbon steel coils requires care. Avoid dragging or bumping them against hard surfaces. This can create dents and scratches. Such damage can weaken the material over time. It’s essential to ensure that lifting equipment is rated for the coils' weight.

Tips: Employ soft slings when lifting to reduce surface damage. Regularly check lifting gear for wear and tear.

Finally, keep records of maintenance activities. Tracking these can help spot patterns or recurring issues. Having a solid maintenance history aids in troubleshooting. It may not prevent every problem, but it can help you make informed decisions about future needs.

| Application | Benefits | Maintenance Best Practices |

|---|---|---|

| Automotive Components | High strength and durability | Regular inspections for rust and corrosion |

| Construction Industry | Cost-effective and versatile material | Proper storage to avoid moisture |

| HVAC Systems | Excellent thermal conductivity | Routine cleaning and check for leaks |

| Manufacturing | High machinability | Use of suitable lubricants during machining |

| Railway Components | Robust performance under heavy loads | Inspect joints and connections regularly |