In the world of manufacturing and construction, Hot Rolled Carbon Steel Coil plays a vital role. Industry expert Jane Smith once remarked, "Hot Rolled Carbon Steel Coil is the backbone of countless industries." This statement underscores the importance of this material in various applications.

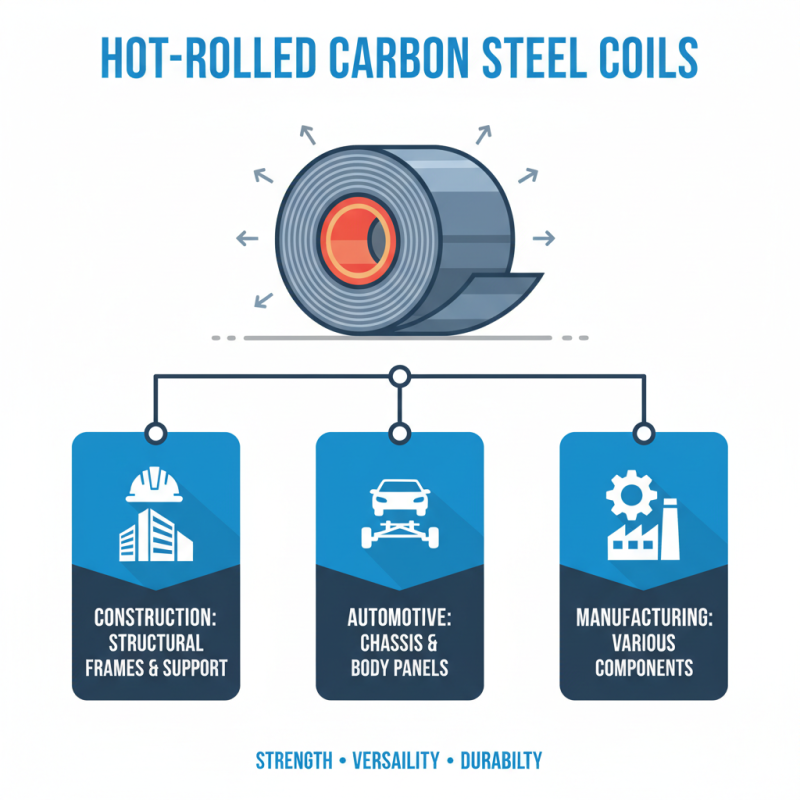

Hot Rolled Carbon Steel Coil is known for its versatility and strength. It is widely used in automotive, construction, and machinery sectors. Its ability to withstand high pressure makes it a preferred choice for structural components. However, not all coils are made equal, and quality can vary significantly.

Some producers use shortcuts that affect the integrity of the steel. Choosing the right supplier is crucial. Health and safety standards should always be a priority when working with this material. Understanding the benefits and potential pitfalls of Hot Rolled Carbon Steel Coil can lead to better decision-making in projects. Consider how the choice of material impacts end products.

Hot rolled carbon steel coils are widely utilized across various industries due to their strength and versatility. They are essential in construction, automotive, and manufacturing sectors. In construction, these coils provide robust materials for structural frames and support. In automotive, they are crucial for chassis and body panels, ensuring durability and safety.

Manufacturers also favor hot rolled steel for its ease of processing. It can be quickly shaped and cut to specific sizes. With minimal finishing required, it reduces production time and costs. This makes it a popular choice in fabricating machinery and equipment. However, it is important to consider that hot rolled steel can have surface imperfections. These may affect the final product's appearance and require further treatment.

**Tips:** When selecting hot rolled carbon steel, evaluate the intended use carefully. Ensure it meets desired specifications for strength and surface quality. Regular inspections during production can help identify any flaws early, saving time and resources in the future.

Hot rolled carbon steel coils are widely used in many industries. They offer several advantages over other types of steel. One major benefit is their lower production cost. The hot rolling process allows for mass production, which reduces prices significantly. This cost-effectiveness makes hot rolled steel a popular choice for construction and manufacturing.

Another advantage is the increased flexibility in shaping and forming. Hot rolled carbon steel can be easily manipulated while still hot. This property allows for the creation of complex shapes without compromising strength. However, these coils can be less precise than cold rolled options. Sometimes, the finish may not be as smooth as desired.

Moreover, hot rolled steel has a unique structural integrity. It retains its strength even under heavy loads. This makes it ideal for structural applications. Yet, it’s essential to consider that hot rolled steel can be less resistant to corrosion. In environments with high humidity or chemical exposure, protective coatings might be necessary. Balancing these factors is crucial in selecting the right material for your project.

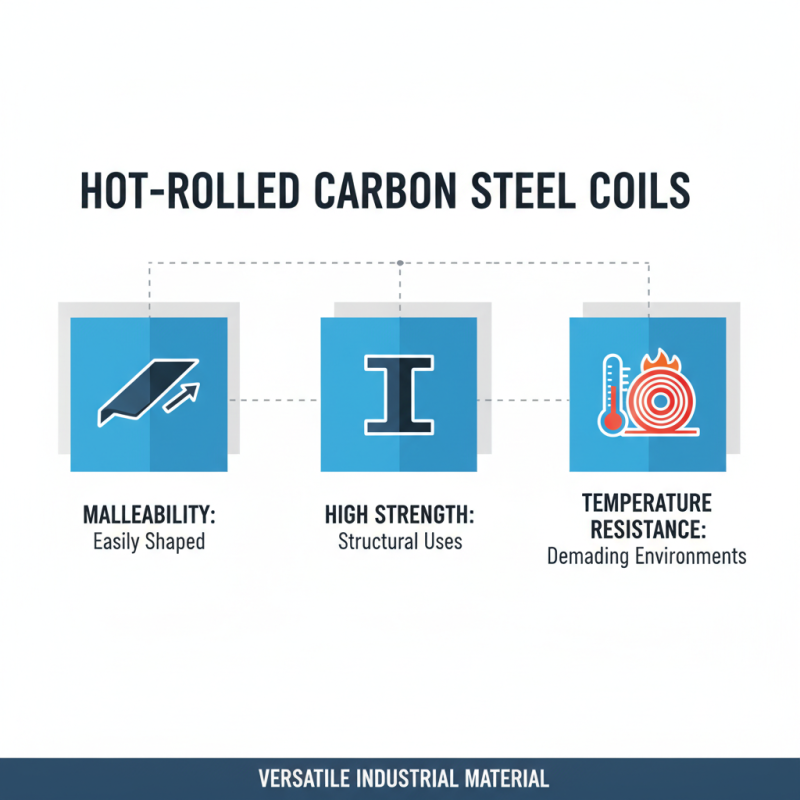

Hot rolled carbon steel coils are widely used due to their unique properties. These coils boast excellent malleability, allowing them to be shaped into various forms without breaking. Their high strength makes them ideal for structural applications. When exposed to high temperatures, they maintain integrity and performance, making them suitable for demanding environments.

One of the key properties of hot rolled carbon steel is its cost-effectiveness. The manufacturing process requires less energy compared to other steel forms. This can lead to lower production costs. However, the trade-off can be lower surface quality. It's crucial to balance cost with the required finish for specific applications.

**Tip:** Consider your project's specific needs. Is surface quality critical? If yes, think about investing in additional finishing processes.

Additionally, hot rolled steel is known for its durability. It resists wear and tear in challenging conditions. But, keep in mind that it may not be the best choice for highly corrosive environments. Regular maintenance and protective coatings are often necessary to prolong its lifespan.

**Tip:** Always assess environmental factors. This could save you time and resources down the line.

Hot rolled carbon steel coils play a vital role in construction. They are commonly used in structural applications. Buildings, bridges, and heavy machinery rely on the strength of these materials. Reports show that over 70% of construction frameworks utilize hot rolled steel. This highlights its significance in modern construction.

In buildings, hot rolled coils form beams, columns, and panels. These components withstand heavy loads and offer durability. According to industry studies, hot rolled steel provides up to 25% more load-bearing capacity compared to cold rolled options. Additionally, this material is cost-effective. Construction projects can save significantly on material costs without sacrificing quality.

However, not all applications are seamless. The surface finish of hot rolled steel may not always meet aesthetic needs. This requires additional treatments or coverings. Moreover, the susceptibility to corrosion can challenge long-term performance. Regular maintenance becomes essential to ensure longevity. Understanding these limitations is crucial for designers and architects. They must weigh the benefits against potential drawbacks.

Hot rolled carbon steel coils have significant environmental implications. These coils are widely used in various industries but come with a cost. The manufacturing process emits pollutants. These emissions can contribute to air and water pollution. Using energy-intensive methods, production negatively impacts climate change.

However, sustainability practices are emerging in the steel industry. Some companies are exploring renewable energy sources. This transition could reduce the carbon footprint of production. Recycling steel is an effective way to minimize waste. Yet, not all steel is recycled, leading to resource depletion.

The industry still faces challenges. Despite advancements, the reliance on fossil fuels is prevalent. Many manufacturers have yet to adopt green practices. Consumer awareness is key to driving change. Public demand for sustainable materials can push for better practices in production.

| Use | Benefits | Environmental Impact | Sustainability Practices |

|---|---|---|---|

| Construction | High strength and durability | Carbon emissions during production | Recycling of scrap steel |

| Automotive | Lightweight, improving fuel efficiency | Resource-intensive manufacturing process | Use of alternative energy in production |

| Manufacturing Equipment | Cost-effective for various applications | Waste generation in production | Implementing cleaner technologies |

| Shipbuilding | Resistance to harsh marine environments | Potential for waterway pollution | Use of sustainable materials in fabrication |

| Agriculture Equipment | Robust and reliable for heavy use | Deforestation for raw material extraction | Support for sustainable sourcing practices |