Coil Carbon Steel is a versatile material widely used in various industries. Its unique features set it apart from other steel types. This article explores its benefits and applications, aimed for 2026.

The flexibility of Coil Carbon Steel allows for diverse uses. Industries such as automotive and construction rely heavily on it. Its strength and formability enable manufacturers to create complex shapes. However, over-reliance on one material can be a risk.

Understanding the characteristics of Coil Carbon Steel is vital. Its availability and cost-effectiveness make it attractive. Still, it's important to consider potential alternatives. Each application may benefit differently, and constant evaluation is key.

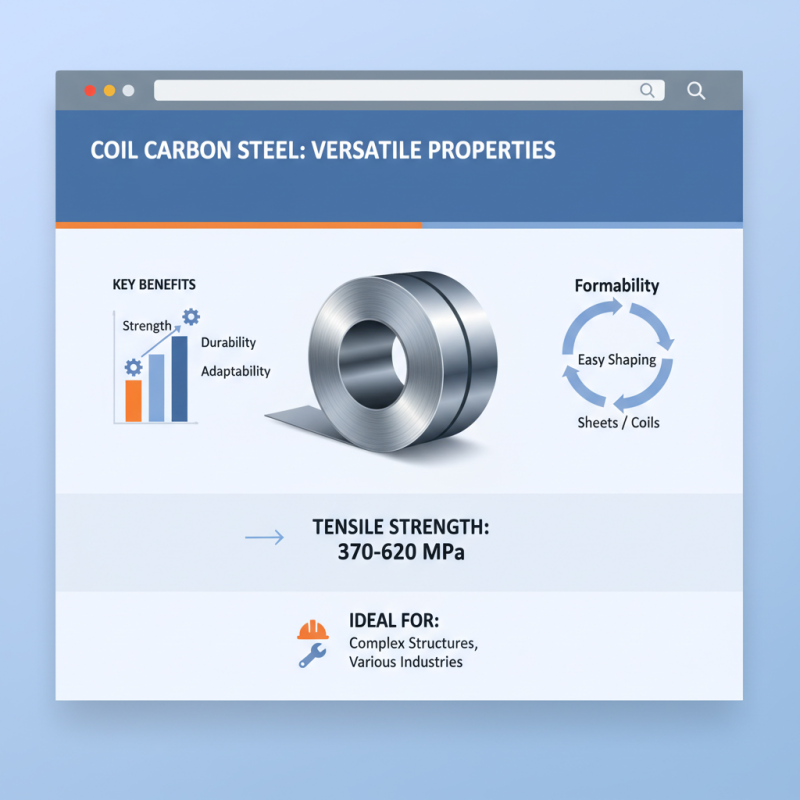

Coil carbon steel is gaining traction in various industries due to its versatile properties. It blends strength, durability, and adaptability, making it ideal for many applications. A critical feature is its formability, which allows for easy shaping into sheets or coils. This adaptability is quantified by a tensile strength range of around 370 to 620 MPa, depending on the specific grade. Such characteristics enable designers and engineers to create complex structures with ease.

Moreover, coil carbon steel often undergoes different processing methods, enhancing its properties further. For instance, cold rolling increases strength while reducing thickness, offering a finely-tuned product for precision applications. Reports indicate that about 50% of carbon steel products are utilized in construction, automotive, and machinery sectors. However, there are challenges with corrosion resistance, requiring protective coatings for specific environments. This aspect must be considered to ensure longevity in applications.

The cost-effectiveness of coil carbon steel is another key aspect. Its production requires less energy compared to alternatives, making it environmentally favorable. Prices can vary significantly, influenced by raw material availability and market demand. Some experts argue that reliance on carbon steel may pose risks due to fluctuating costs. Therefore, industries need to balance their choices carefully while considering future trends and sustainability.

Coil carbon steel is known for its mechanical properties, particularly strength and ductility. This material often boasts a yield strength of up to 250 MPa, depending on its composition. This strength is crucial for applications in construction and manufacturing, where loads can be significant. Ductility allows the steel to bend without breaking, making it essential for forming processes.

In industry reports, it’s noted that coil carbon steel can achieve elongation rates of around 20% in tensile tests. This is impressive, yet it presents a challenge in maintaining uniformity. Variability in processing can lead to performance discrepancies. For instance, if the steel is not properly cooled, it may lack the desired ductility. This could result in brittle failure under load.

Furthermore, coil carbon steel is often used in automotive and appliance industries due to its favorable mechanical properties. The balance between strength and ductility can enhance safety features while reducing weight. However, engineers must carefully consider alloying elements. A miscalculation can lead to unforeseen weaknesses. The quest for the best balance continues, highlighting the need for ongoing research and innovation in material science.

Coil carbon steel is a versatile material widely used across various industries. Its strength and toughness make it ideal for manufacturing components. The automotive industry heavily relies on coil carbon steel due to its durability. Reports show that around 50% of steel used in car production is carbon steel. This material's ability to be easily formed into complex shapes also adds to its appeal.

Construction is another sector where coil carbon steel finds extensive applications. Approximately 30% of structural steel used in buildings is carbon steel. Its resistance to deformation under load ensures safety and longevity. Additionally, coil carbon steel is often used for making pipes and tubing, which are essential in infrastructure projects.

However, there are challenges. The production of high-quality coil carbon steel can be energy-intensive. This raises questions about sustainability in the long term. Additionally, improper handling can lead to rust or degradation. As industries continue to evolve, it remains crucial to address these concerns while maximizing the benefits of coil carbon steel.

Coil carbon steel is known for its remarkable cost-effectiveness. In recent industry reports, it is noted that coil steel can reduce material costs by up to 20% compared to other steel types. This is crucial for manufacturers aiming for affordability. The lower material costs help in maintaining competitive pricing in the market.

Additionally, coil carbon steel boasts impressive durability. Its strength allows it to withstand harsh conditions and heavy loads. Recent studies indicate that projects using coil carbon steel report a 30% increase in lifespan compared to traditional materials. This longevity translates to fewer replacements and reduced maintenance costs over time.

However, it’s important to consider the potential for rusting and corrosion. While some treatments can mitigate this risk, not all steel providers implement these consistently. This inconsistency can lead to unexpected failures and financial losses. It's crucial for buyers to conduct thorough research into the specific grades and finishes of coil carbon steel they plan to use.

The coil carbon steel market is expected to see significant innovations in 2026. Advances in production techniques will focus on sustainability. Manufacturers are exploring options to reduce waste and energy consumption. New methods may enhance the quality of the steel produced while lowering costs. This could change how industries utilize coil carbon steel.

In various applications, from construction to automotive, coil carbon steel plays a pivotal role. The demand for lightweight and durable materials grows each year. Innovations are crucial, yet challenges remain. Some manufacturers still rely on outdated practices that harm efficiency. Additionally, the market's fluctuation in raw material prices affects production stability. These issues warrant attention for future improvements as companies look to stay competitive.

Technological integration, such as automation, is redefining production lines. However, this transition raises concerns about job displacement. Training programs need to address this gap. As the market evolves, collaboration between industry players becomes vital for fostering innovation. Addressing these aspects will shape the future of coil carbon steel production.