In the world of construction and manufacturing, the choice of materials significantly influences the overall efficiency and sustainability of projects. Among various options, low carbon steel coils have emerged as a favored choice for many professionals. Renowned expert in metallurgy, Dr. Richard Hall, emphasizes the advantages of these materials, stating, "Low carbon steel coils offer exceptional flexibility and strength, making them ideal for a wide range of applications." This statement underlines the growing recognition of the benefits associated with Steel Coils Low Carbon Strips.

The utilization of Steel Coils Low Carbon Strips not only enhances structural integrity but also supports sustainable practices in various industries. Their lightweight yet durable characteristics allow for reduced transportation costs and ease of installation, which can lead to significant cost savings in large projects. Furthermore, low carbon steel’s recyclability contributes to a more environmentally friendly approach, as it minimizes waste and promotes resource efficiency.

Understanding the top benefits of using low carbon steel coils can empower project managers and engineers to make informed decisions. In the following sections, we will explore the key advantages that make Steel Coils Low Carbon Strips an essential material for modern construction and industrial applications.

Low carbon steel coils have emerged as a vital material in both construction and manufacturing settings, owing to their unique combination of strength, ductility, and cost-effectiveness. According to a report by the World Steel Association, low carbon steel accounts for approximately 90% of the total steel production globally. This widespread use is attributed to its excellent weldability and formability, making it suitable for various applications, including beams, pipes, and automotive components. The material's low carbon content allows for significant deformation without fracture, which is crucial in meeting the rigorous demands of modern engineering projects.

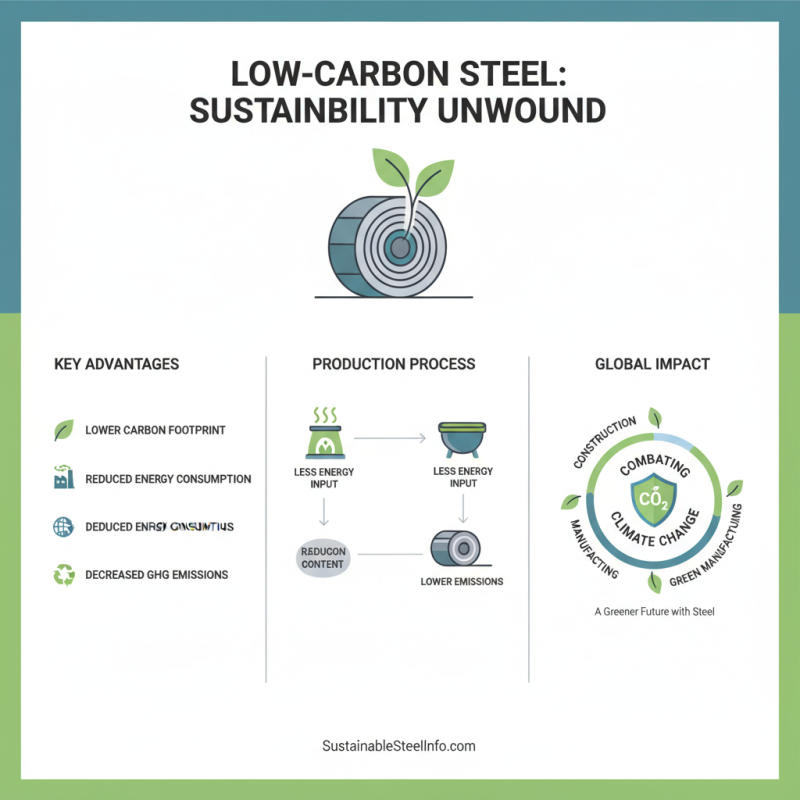

Furthermore, the environmental benefits of low carbon steel coils cannot be overlooked. A study from the American Institute of Steel Construction highlights that using low carbon steel can lead to a reduction in greenhouse gas emissions by up to 30% compared to higher carbon alternatives. The recycling capabilities of low carbon steel also contribute to its sustainability profile, with the Steel Recycling Institute reporting that more than 75% of steel produced in the U.S. is recycled, further minimizing waste and resource use in construction and manufacturing. As industries shift towards more sustainable practices, the adoption of low carbon steel coils remains a significant factor in enhancing productivity while supporting environmental goals.

When it comes to large-scale projects, managing costs efficiently is crucial. Low carbon steel coils offer a compelling solution for budget-conscious organizations, primarily due to their affordability and versatility. The inherent properties of low carbon steel make it a cost-effective material for various applications, from automotive parts to structural components. Not only are these steel coils generally less expensive than higher carbon alternatives, but their strength allows for the use of thinner gauges, which can further reduce material costs without compromising structural integrity.

In addition to the initial savings, low carbon steel coils can significantly lower manufacturing and processing costs. Their excellent formability and weldability make them ideal for quick processing, resulting in reduced labor costs and increased production efficiency. Moreover, the lightweight nature of low carbon steel means lower transportation and handling expenses. For contractors and project managers, these factors translate into substantial overall savings, making low carbon steel coils an attractive choice for large-scale construction and manufacturing endeavors.

Low carbon steel coils are widely recognized for their remarkable durability and strength characteristics, making them an ideal choice for various construction and manufacturing projects. With a carbon content typically between 0.05% to 0.25%, low carbon steel exhibits a high degree of malleability and ductility, allowing it to withstand significant stress and deformation without cracking. This flexibility not only enhances the structural integrity of projects but also ensures long-lasting performance under varying environmental conditions, reducing the need for frequent repairs or replacements.

When using low carbon steel coils, it's essential to consider certain tips for maximizing their benefits. First, ensure proper handling during installation to avoid any unnecessary damage, such as dents or scratches, which could compromise their protective coatings and lead to corrosion over time. Second, implementing adequate welding techniques is crucial, as low carbon steel can easily be welded, providing strong joints that contribute to the overall durability of the structure. Lastly, regular maintenance checks can help identify any signs of wear, enabling proactive measures to preserve the integrity of the steel and extend its lifespan.

In summary, the strength and durability characteristics of low carbon steel coils make them a superior choice for many applications. By taking care during installation, employing effective welding methods, and conducting routine maintenance, projects utilizing these steel coils can achieve optimal performance and longevity.

Low carbon steel coils are increasingly recognized for their environmental advantages, making them a preferred choice for sustainable construction and manufacturing projects. One of the primary benefits is their lower carbon footprint compared to other steel types. Since low carbon steel contains reduced levels of carbon, it requires less energy to produce, leading to decreased greenhouse gas emissions during the manufacturing process. This characteristic aligns well with global efforts to minimize environmental impact and combat climate change, promoting a more sustainable industry.

Furthermore, low carbon steel coils are highly recyclable, which significantly contributes to their eco-friendliness. Steel can be repurposed multiple times without losing its properties, promoting a circular economy. This cycle not only reduces the demand for virgin raw materials but also minimizes waste by diverting old steel from landfills. By using low carbon steel coils in various applications, industries can take significant strides towards resource conservation and environmental preservation, ultimately fostering a healthier planet for future generations.

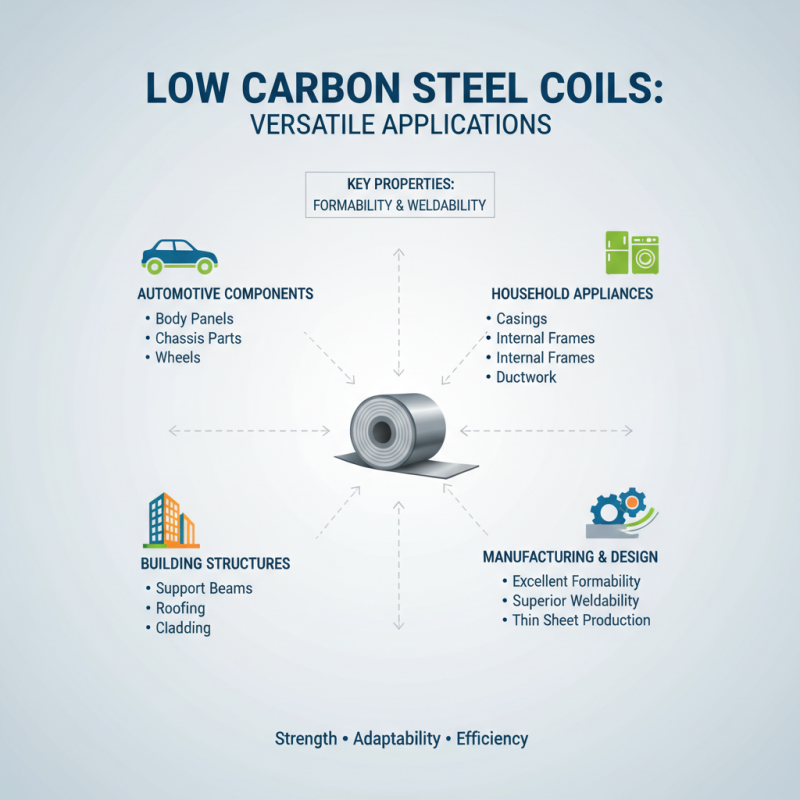

Low carbon steel coils are highly versatile materials that can be employed across a variety of applications due to their unique properties. Their excellent formability and weldability make them an ideal choice for manufacturing processes, including the production of automotive components, building structures, and household appliances. Moreover, low carbon steel’s ability to be rolled and shaped into thin sheets offers designers and engineers the flexibility to create intricate shapes without compromising strength or structural integrity.

In the construction industry, low carbon steel coils are frequently used for frames, roofs, and other structural components, as they provide reliable support while being lightweight and cost-effective. Additionally, these coils are often utilized in the production of tubing and piping, which are essential for fluid transport in industrial settings. The combination of durability and corrosion resistance found in low carbon steel allows it to perform well in both indoor and outdoor environments, further expanding its applicability in fields such as manufacturing, construction, and infrastructure development. This adaptability is a key reason why low carbon steel coils continue to be a preferred material for countless projects around the globe.