The significance of materials in manufacturing cannot be overstated, as they directly impact product quality, cost-efficiency, and overall performance. Among the various materials utilized, Carbon Steel Roll Coil has emerged as a highly advantageous option for manufacturers across multiple sectors. Its unique combination of strength, durability, and versatility makes it an ideal choice for a wide array of applications, ranging from automotive components to construction materials.

In this exploration of the top benefits of using Carbon Steel Roll Coil in manufacturing, we will delve into the attributes that make this material so valuable. From its excellent mechanical properties to its cost-effectiveness, Carbon Steel Roll Coil offers solutions that can enhance production processes and improve end-product performance. As industries continue to seek innovative materials to meet evolving demands, understanding the benefits of Carbon Steel Roll Coil will equip manufacturers with the knowledge to make informed decisions that will ultimately drive efficiency and success in their operations.

Carbon steel roll coils have become a cornerstone in the manufacturing industry, providing a versatile solution for a variety of applications. Characterized by their excellent strength-to-weight ratio, carbon steel roll coils are particularly favored for their structural integrity and durability. According to a report by the Steel Manufacturers Association, carbon steel consumption is projected to increase by 3% annually, indicating its growing significance in manufacturing processes. These coils are produced in standardized widths and can be easily customized in thickness, making them ideal for industries ranging from construction to automotive production.

When incorporating carbon steel roll coils into production, manufacturers often discover significant economic advantages. The cost-effectiveness of carbon steel, combined with its recyclability, aligns with sustainable manufacturing practices. An industry study by the World Steel Association highlights that recycling carbon steel saves approximately 75% of the energy required to produce new steel. Additionally, the ease of processing carbon steel enables faster production times, allowing manufacturers to meet market demands with greater efficiency.

Tips: To maximize the benefits of carbon steel roll coils, consider optimizing your supply chain to reduce delivery times. Regularly evaluate your sourcing strategies and maintain relationships with suppliers who can provide high-quality materials promptly. Additionally, implementing quality control measures during fabrication can help ensure that the final products meet stringent industry standards.

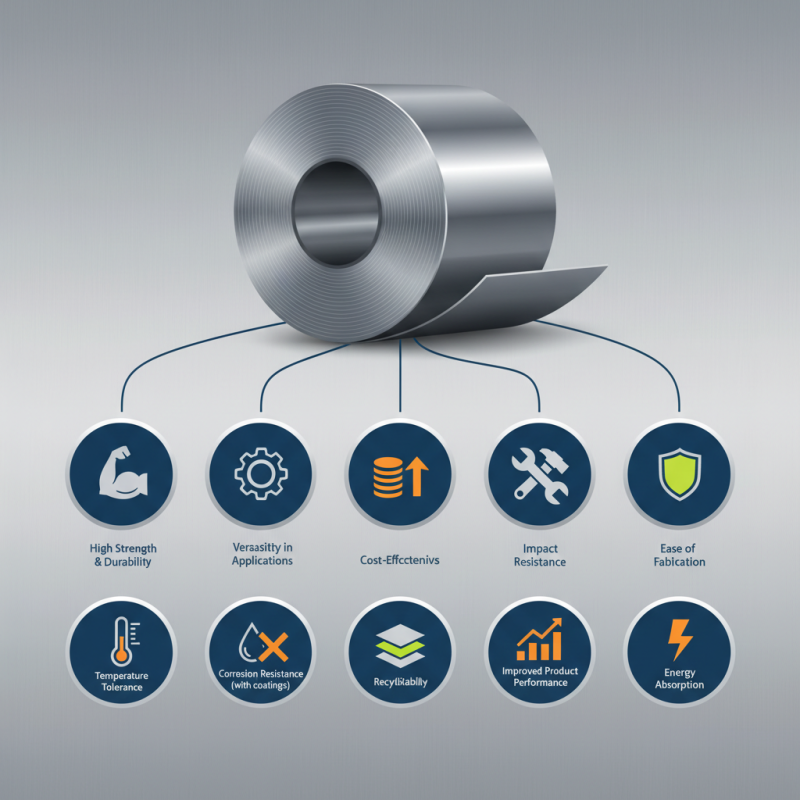

This chart illustrates the top 10 benefits of using carbon steel roll coil in manufacturing, with ratings from 1 to 10. Each benefit demonstrates its significance in the production process.

Carbon steel roll coil is a versatile material commonly used in various industrial applications due to its unique characteristics. One of the key features of carbon steel is its strength and durability, which make it suitable for demanding manufacturing environments. Carbon steel offers excellent tensile strength, allowing it to withstand heavy loads and stress without deformation. This property is essential for industries such as construction and automotive manufacturing, where the integrity of materials directly impacts safety and performance.

Another significant characteristic of carbon steel roll coil is its malleability and workability. This allows manufacturers to easily form and shape the material into desired specifications without compromising its structural integrity. The ability to be rolled, stamped, or welded makes carbon steel an ideal choice for producing components such as beams, frames, and other structural elements. Furthermore, carbon steel possesses good corrosion resistance when properly treated, enhancing its longevity in various applications. This combination of strength, workability, and durability makes carbon steel roll coil a preferred material across multiple sectors in the manufacturing industry.

Carbon steel roll coils are recognized for their enhanced durability and strength, making them a favored choice in various manufacturing processes. One of the primary advantages of carbon steel is its ability to withstand considerable stress and strain without compromising structural integrity. This makes it particularly valuable in applications where reliability is paramount. The metallurgical properties of carbon steel contribute to its hardness and tensile strength, allowing for the creation of robust products that can endure harsh working conditions.

Moreover, the manufacturing process of carbon steel roll coils involves precise control over the alloying elements, which further boosts their performance. These coils can be readily formed or shaped into different components while maintaining their resilience, enabling manufacturers to reduce waste and optimize production efficiency. The consistent quality and mechanical properties of carbon steel roll coils also facilitate easier and faster assembly in construction and heavy machinery sectors, where safe and efficient operations are crucial. By leveraging the superior durability and strength of carbon steel roll coils, manufacturers can achieve long-lasting, high-performance products that meet rigorous industrial demands.

The cost-effectiveness of carbon steel roll coil in manufacturing processes is a significant factor driving its widespread adoption across various industries. Carbon steel is known for its balance of affordability and performance, making it an ideal choice for manufacturers looking to optimize production costs while maintaining high-quality standards. Its availability in large roll coils allows for efficient use of material, reducing waste and minimizing the cost of raw materials. This economical advantage enables manufacturers to scale their operations without overwhelming financial burdens.

In addition to its low initial cost, carbon steel roll coil offers versatility in manufacturing processes. It can be easily shaped and formed into a variety of products, from structural components to automotive parts, which helps in reducing additional expenses related to fabrication. The durability of carbon steel also means that products made from it tend to have a longer lifespan, decreasing the need for frequent replacements and repairs. This longevity translates to lower maintenance costs, further enhancing its cost-effectiveness in long-term manufacturing strategies. Consequently, choosing carbon steel roll coil is not just about upfront savings; it's about creating a sustainable and economically efficient production lifecycle.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| High Durability | Carbon steel roll coil is known for its strength and durability, making it suitable for various applications. | Reduces the need for frequent replacements, saving long-term costs. |

| Versatility | Can be used in a wide range of manufacturing processes, enhancing productivity. | Lower inventory costs as fewer materials are required. |

| Ease of Fabrication | Carbon steel is easy to cut, weld, and shape, streamlining operations. | Decreases labor costs and time in manufacturing processes. |

| Cost-Effective Material | Generally cheaper than other materials with similar properties. | Direct impact on reducing overall manufacturing costs. |

| Excellent Strength-to-Weight Ratio | Provides high strength while maintaining a lightweight profile. | Optimal for reducing transportation costs due to weight savings. |

| Global Availability | Widely available across the globe, ensuring consistent supply. | Stability in pricing and availability reduces financial risks. |

| Adaptability to Coatings | Can be easily coated for corrosion resistance and aesthetic purposes. | Enhances product life, which is cost-effective in long-term usage. |

| Recyclability | Carbon steel is 100% recyclable, promoting sustainability. | Reduces material disposal costs and can generate revenue through recycling. |

| Enhanced Performance | Improved performance in demanding applications. | Minimizes costs associated with failures and warranty claims. |

| Support for Innovation | Facilitates the use of innovative manufacturing processes. | Long-term savings through improved efficiency and innovation. |

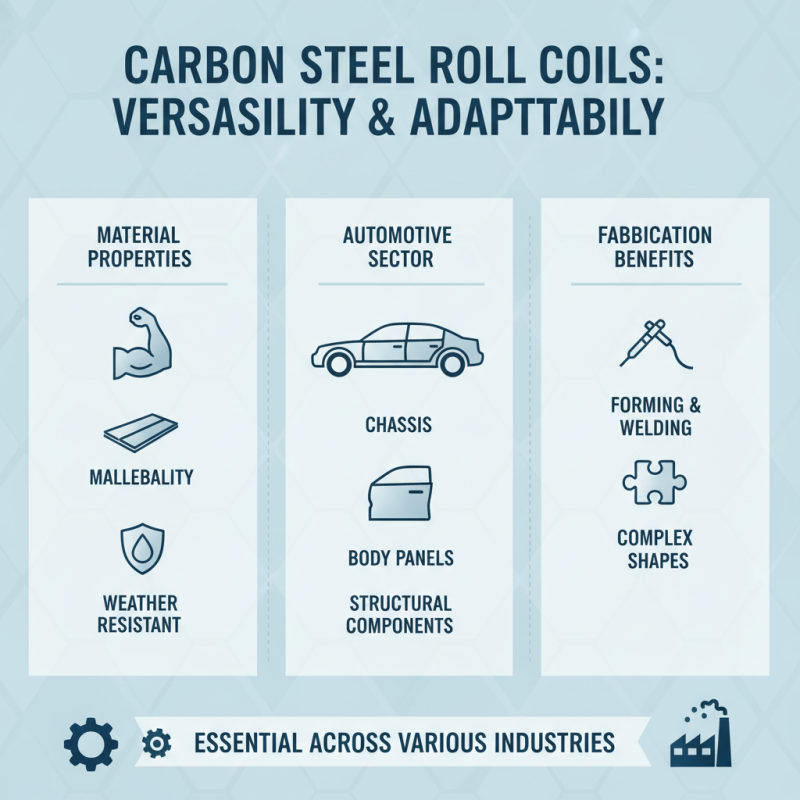

Carbon steel roll coils are an essential material across various industries due to their remarkable versatility and adaptability. In the automotive sector, for instance, the strength and malleability of carbon steel make it an ideal choice for manufacturing chassis, body panels, and structural components. This material can be easily formed and welded, allowing for complex shapes and designs that enhance the performance and aesthetic of vehicles. Additionally, carbon steel's ability to withstand harsh environmental conditions makes it suitable for outdoor applications, further broadening its usage in automotive production.

In the construction industry, carbon steel roll coils play a crucial role in fabricating structural frameworks, roofing materials, and piping systems. The durability and high tensile strength of carbon steel ensure that structures can withstand significant loads and stress over time. Moreover, the cost-effectiveness of carbon steel allows for budget-friendly solutions in large-scale projects. Its recyclability further enhances its appeal, positioning it as a sustainable choice for construction professionals looking to minimize their environmental footprint. Overall, the versatility of carbon steel roll coils allows them to meet the diverse needs of various sectors, promoting innovation and efficiency in manufacturing processes.