In the ever-evolving landscape of manufacturing, the selection of materials plays a pivotal role in determining a product's overall performance and sustainability. Among various options, Steel Coils Low Carbon Strips have emerged as a favored choice due to their versatile properties and environmental benefits. According to a report by the World Steel Association, low carbon steel accounts for approximately 60% of the global steel production, underscoring its dominance and trust within the industry. Utilizing these strips not only enhances the production process but also aligns with sustainable manufacturing practices, significantly reducing carbon emissions during fabrication.

In the ever-evolving landscape of manufacturing, the selection of materials plays a pivotal role in determining a product's overall performance and sustainability. Among various options, Steel Coils Low Carbon Strips have emerged as a favored choice due to their versatile properties and environmental benefits. According to a report by the World Steel Association, low carbon steel accounts for approximately 60% of the global steel production, underscoring its dominance and trust within the industry. Utilizing these strips not only enhances the production process but also aligns with sustainable manufacturing practices, significantly reducing carbon emissions during fabrication.

Moreover, the use of Steel Coils Low Carbon Strips offers a myriad of advantages such as improved malleability, weldability, and tensile strength, making them an ideal choice for a diverse range of applications, from automotive components to consumer electronics. A market analysis from IBISWorld reveals that the demand for low carbon steel is expected to grow steadily, driven by the increasing emphasis on environmentally friendly materials. This trend highlights the necessity for manufacturers to adapt and embrace low carbon solutions, reinforcing the critical role that Steel Coils Low Carbon Strips will continue to play in shaping the future of manufacturing.

Low carbon steel coils and strips are increasingly recognized for their significant advantages in modern manufacturing processes. Their malleability and ductility enable manufacturers to easily fabricate complex shapes without cracking or breaking, making them ideal for various applications. This attribute not only enhances design flexibility but also reduces waste material during production, which can lead to cost savings that are critical in competitive markets. Additionally, their excellent weldability facilitates streamlined assembly processes, further optimizing manufacturing efficiency.

Recent market trends indicate a growing demand for low carbon steel products. According to industry reports, the global low carbon steel market is projected to witness substantial growth, driven by robust industrial activities and infrastructure development. As companies prioritize sustainable manufacturing practices, low carbon steel coils and strips become an attractive option because they can be sourced sustainably and recycled efficiently, supporting green initiatives. The blend of performance and sustainability is pivotal as manufacturers strive to meet both economic and environmental goals in today's evolving landscape.

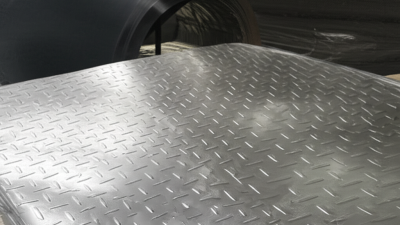

Low carbon steel coils and strips have become increasingly popular in various industrial applications due to their enhanced durability and strength. With a carbon content typically ranging from 0.04% to 0.30%, low carbon steel offers excellent malleability and ductility, making it easy to fabricate into different shapes while maintaining structural integrity. This inherent flexibility enables manufacturers to produce components that can withstand considerable mechanical stress without succumbing to deformation.

In applications where resilience is critical, low carbon steel coils excel. Their toughness is particularly beneficial in industries such as automotive, construction, and machinery, where components are subject to heavy loads and harsh environments. The material's ability to endure fatigue and impact without losing its form enhances the lifespan of manufactured products. Additionally, low carbon steel's resistance to corrosion, especially when galvanized, ensures that critical parts remain functional and reliable, reducing maintenance costs and downtime. This combination of strength, durability, and longevity is what makes low carbon steel coils an optimal choice for manufacturers seeking to improve the performance of their products.

Low carbon steel coils and strips present a cost-effective solution for manufacturers looking to optimize their production processes. This material provides an excellent balance of strength and ductility, enabling manufacturers to create durable products while minimizing material waste. Moreover, low carbon steel is relatively inexpensive compared to other steel grades, allowing companies to reduce their overall manufacturing costs significantly without compromising quality.

Tips for manufacturers considering low carbon steel coils include evaluating the specific requirements of their production line. Assessing factors such as tensile strength and yield point is crucial to ensure they select the right type of low carbon steel for their applications. Additionally, efficient supply chain management can further enhance cost-effectiveness; working closely with suppliers to negotiate bulk orders may yield further savings.

Another benefit of utilizing low carbon steel coils is their contribution to sustainability initiatives. By opting for materials that require less energy in the production process, manufacturers can align with decarbonization goals while also appealing to environmentally conscious consumers. Incorporating low carbon steel into manufacturing not only helps in reducing carbon footprints but also enhances the company's reputation in a market increasingly focused on sustainability.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| High Strength | Low carbon steel coils offer excellent tensile strength, making them reliable for various manufacturing needs. | Reduced material costs due to fewer defects and reworks. |

| Versatility | These coils can be easily shaped and formed, suitable for a variety of products. | Saves money on manufacturing tools and processes. |

| Weldability | Low carbon steel is easy to weld, allowing for quick assembly and construction. | Decreases labor costs by speeding up production time. |

| Lightweight | Compared to other metals, low carbon steel coils are lightweight, facilitating easier handling. | Minimizes shipping and handling costs. |

| Cost Efficiency | Lower costs of raw materials direct to better manufacturing efficiency. | Significantly reduces overhead expenses. |

| Corrosion Resistance | With proper coating, low carbon steel can be highly resistant to corrosion. | Extends lifespan of products, reducing replacement costs. |

| Sustainability | Recycling low carbon steel is easy, promoting sustainability in manufacturing. | Keeps waste and disposal costs low. |

| Economic Stability | Availability of low carbon steel helps stabilize costs in the industry. | Fosters predictable budgeting for manufacturers. |

| Availability | Easily accessible in various sizes and specifications. | Reduces lead time and inventory costs. |

| Customization | Manufacturers can customize products to meet specific client needs. | Enhances customer satisfaction, promoting repeat business. |

Low carbon steel coils and strips are playing a crucial role in promoting sustainability within the manufacturing sector. Their production process typically requires less energy compared to high carbon steel, leading to reduced greenhouse gas emissions. This shift not only lessens the environmental impact but also aligns with the industry's movement towards more sustainable practices. By utilizing low carbon steel, manufacturers contribute to a circular economy, allowing for easier recycling and reusability of materials.

Tips for Manufacturers:

Consider investing in low carbon steel coils to improve your sustainability profile. This transition can not only enhance your brand's reputation but also attract environmentally conscious consumers. Additionally, look for suppliers that prioritize

green manufacturing processes, ensuring that the materials you source adhere to sustainability standards.

The long-term benefits of low carbon steel extend beyond environmental impact—they also include improved performance in manufacturing applications. Products made with low carbon steel often exhibit enhanced ductility, making them suitable for various applications while reducing waste during production. Embracing these materials is not just a step towards sustainability; it's a strategic move towards greater efficiency and cost-effectiveness in manufacturing.

Low carbon steel coils have become a vital material in diverse manufacturing industries due to their exceptional versatility. Their properties, including malleability, ductility, and weldability, make them ideal for various applications ranging from construction to automotive. In the automotive sector, low carbon steel coils are commonly used in body panels and chassis, where strength and lightweight qualities are crucial. Similarly, in construction, these coils facilitate the production of structural components that require reliable and durable materials, further enhancing their utility across the industry.

Moreover, the adaptability of low carbon steel coils in manufacturing processes, such as bending and cutting, underscores their importance. Manufacturers benefit from these coils' ease of processing and their ability to be formed into complex shapes without compromising integrity. As industries continue to evolve and demand materials that balance performance and cost-effectiveness, low carbon steel coils will remain at the forefront, driving innovation and efficiency in modern manufacturing practices.