In the ever-evolving market of construction materials, understanding Steel Plate Carbon Steel Coil is essential. Experts like John Smith, a renowned metallurgist, emphasize, "Choosing the right steel coil can make or break your project." This insight underlines the importance of informed purchasing decisions.

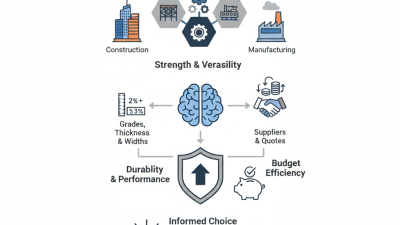

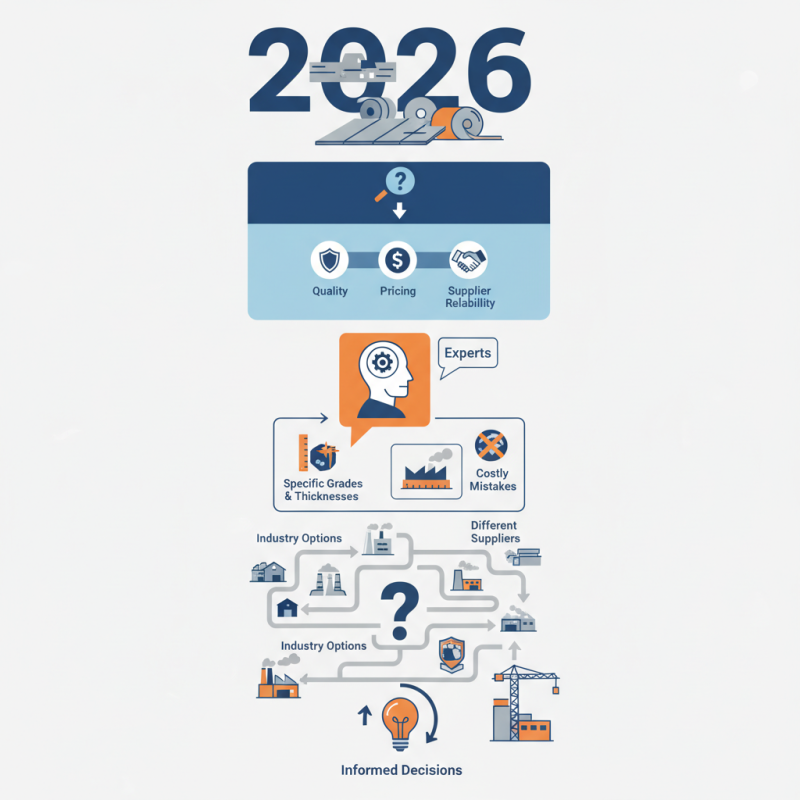

When selecting Steel Plate Carbon Steel Coil, many factors come into play. Quality, pricing, and supplier reliability stand out as crucial aspects. Buyers often overlook specific grades and thicknesses that fit their needs best. This lack of attention can lead to costly mistakes and frustrations later on.

The industry is rife with options, making it both exciting and overwhelming. A novice buyer may feel lost amid different suppliers and technical specifications. Moreover, many are unsure of what actually constitutes a high-quality Steel Plate Carbon Steel Coil. It's important to reflect on these challenges to ensure the right choices are made. Awareness can lead to better outcomes in every project.

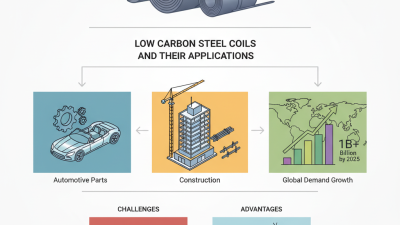

Carbon steel coils are vital in various industrial applications. Understanding their types and properties is crucial for informed buying decisions. Carbon steel, primarily composed of iron and carbon, is categorized into three main types: low, medium, and high carbon steels. Low carbon steels, with around 0.05-0.25% carbon content, provide excellent ductility and weldability. These properties make them ideal for automotive and construction industries.

Medium carbon steels fall in the range of 0.25-0.60% carbon. They balance strength and ductility. On the other hand, high carbon steels, containing over 0.60% carbon, offer exceptional hardness and wear resistance. However, they can be challenging to work with due to their brittleness. According to a recent market report, the global carbon steel coil market is projected to reach $250 billion by 2026, emphasizing its significant role in structural applications.

Selecting the right type requires careful consideration. Each type has unique strengths and weaknesses. For instance, while low carbon steels are favorable for forming, high carbon steels excel in durability. However, the processing and cost can pose challenges. Ultimately, recognizing these nuances can lead to better outcomes in project execution.

This chart displays the tensile strength of various types of carbon steel coils. Understanding the mechanical properties of different steel types is crucial for making informed purchasing decisions in the industry.

When buying steel plate carbon steel coils, several key factors come into play. First, consider thickness. Coils come in various gauges. Thicker plates provide more strength but may increase costs. Think about the applications. Will you use them for construction or manufacturing? Understanding your needs is vital.

Next, examine the steel grade. Different grades offer various properties. Some have better corrosion resistance; others are more malleable. Ensure the grade aligns with your project requirements. Don’t forget to look at weight. Heavier coils can be more challenging to handle. How will you transport and store them?

Price is also an important aspect to weigh. Sometimes, lower prices can mean lower quality. Balancing cost and quality requires careful thought. It can be tempting to go for the cheapest option. But cheaper doesn’t always equal better in the long run. Choosing the right steel coil is a blend of science and art.

| Dimension | Thickness (mm) | Width (mm) | Length (m) | Weight (kg) | Yield Strength (MPa) | Tensile Strength (MPa) | Standard |

|---|---|---|---|---|---|---|---|

| Standard Carbon Steel | 10 | 1500 | 6 | 750 | 250 | 400 | ASTM A36 |

| High-Strength Carbon Steel | 8 | 1200 | 8 | 960 | 300 | 500 | ASTM A572 |

| Structural Carbon Steel | 12 | 2000 | 5 | 1200 | 350 | 600 | ASTM A992 |

| Low Alloy Carbon Steel | 6 | 1000 | 10 | 800 | 320 | 480 | ASTM A588 |

When exploring the market for carbon steel coils in 2026,

it's crucial to focus on reputable manufacturers. These companies set the standard for quality and reliability.

A good manufacturer should offer a comprehensive range of products, including different grades and sizes of carbon steel coils.

It’s not just about quantity; attention to detail is equally important.

Consumers often overlook critical factors such as sourcing and production methods. Transparency in how materials are processed can influence long-term performance.

Some manufacturers follow sustainable practices, which can be a plus. However, not all brands emphasize eco-friendly methods.

Researching their approach can save you from potential pitfalls.

Selecting a supplier requires due diligence. Reviews and industry reputation play significant roles.

Finding feedback from other customers is key. Consider how companies handle customer service and support.

Unresponsive or unhelpful service can lead to frustration.

In the end, the right choice can make a big difference in product satisfaction.

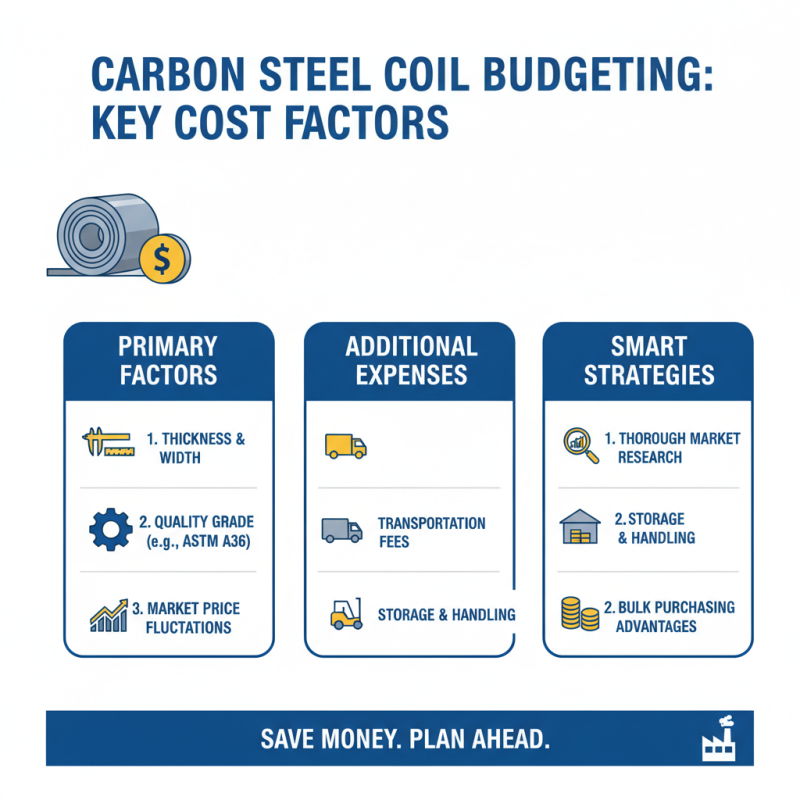

When budgeting for carbon steel coil, cost is a crucial factor. The price can vary widely. Factors such as thickness, width, and quality all influence the final cost. Additionally, transportation and storage fees add to your overall expenses. Conduct thorough research on current market prices. This will help you understand potential price fluctuations.

Tip: Always request multiple quotes. This gives you a clearer picture of the best price available.

Consider long-term usage. Buying in bulk may seem daunting. However, it often leads to significant savings. Ensure your purchase aligns with your future projects. If your needs change, you might be stuck with excess material. Clarifying this in advance can prevent waste.

Tip: Keep a close eye on inventory levels. Mismanagement can lead to increased costs.

Finally, anticipate hidden costs. These might include taxes, tariffs, or supplier fees. A well-prepared budget accounts for all possible expenses. Failing to do so can lead to last-minute financial strain. Reflect on your budget strategy before making a decision. Being prepared is key to a successful purchase.

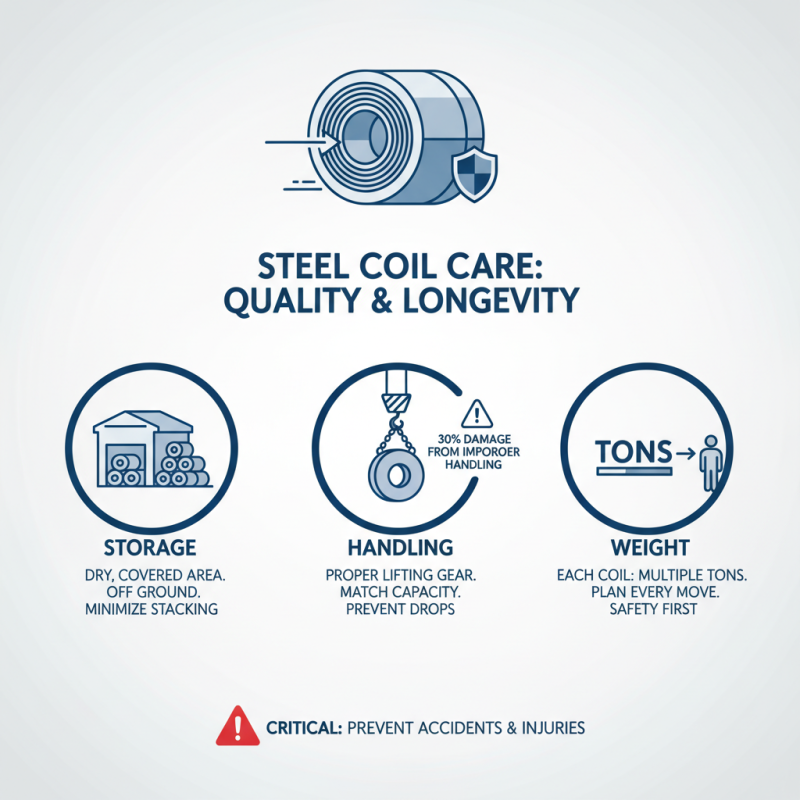

Proper storage and handling of steel plate carbon steel coils are critical for maintaining quality and ensuring longevity. According to industry reports, over 30% of coil damage occurs during improper handling. Each coil weighs several tons, meaning that every move needs careful consideration. A lifting device should have the appropriate capacity to prevent accidents and injuries.

The environment where coils are stored plays a significant role. A climate-controlled facility reduces the risk of corrosion. Humidity levels must be monitored regularly. Ideally, levels should stay below 50%. Inadequate storage can lead to rust formation, costing the industry millions in repairs and replacement. From a storage perspective, coils should be stacked on a flat surface, not in a heap, to prevent deformation or damage.

Regular inspection is vital. Industry data suggests that inspecting coils every 30 days increases longevity by 25%. Damage can go unnoticed if left unchecked. The use of protective coverings can mitigate exposure to environmental factors. While it may seem like an added expense, it is a necessary investment for the quality of the steel. This industry requires constant vigilance. Attention to detail can make a significant difference.