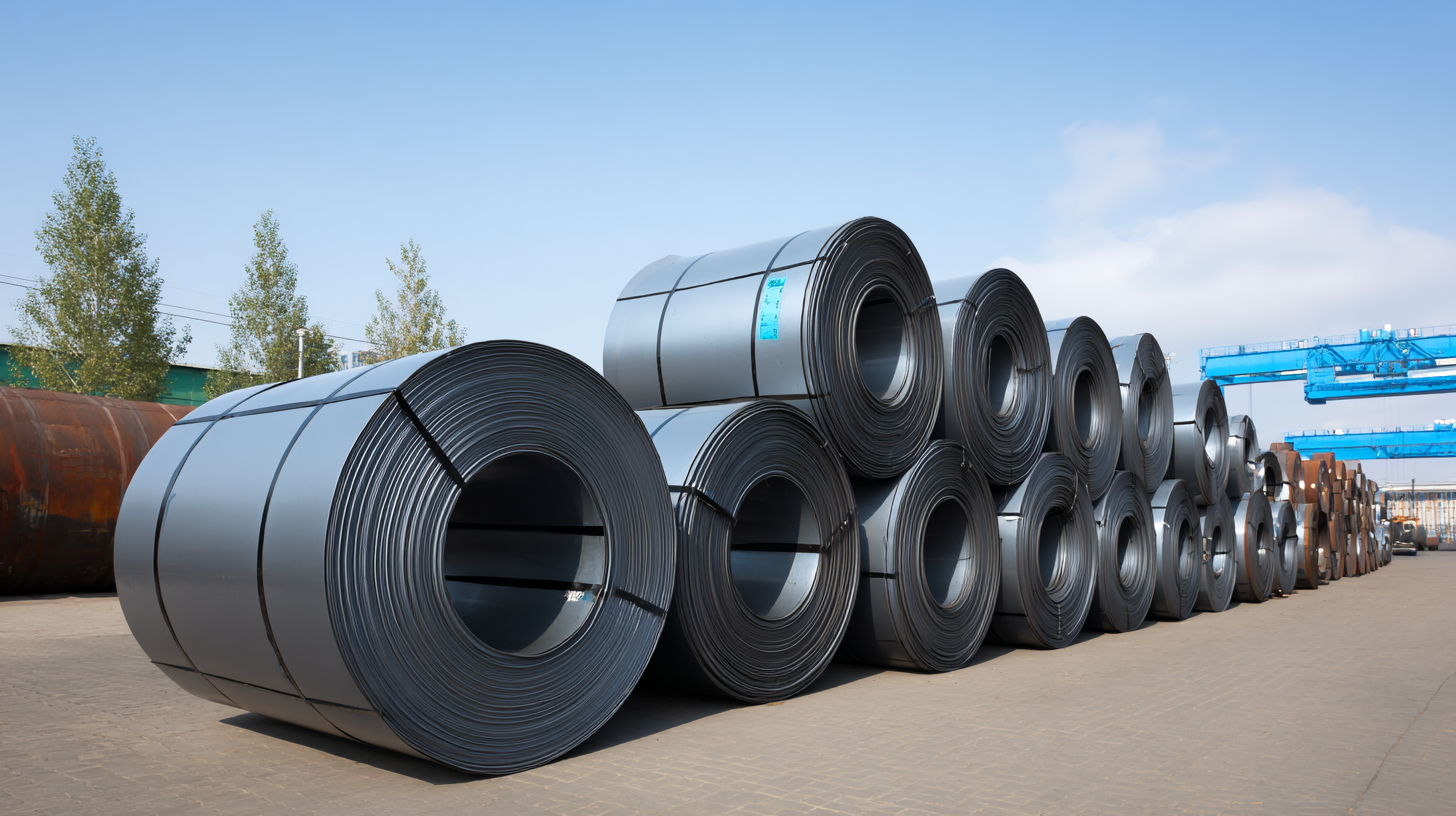

In the ever-evolving landscape of industrial materials, Cold Rolled Carbon Steel Coil has emerged as a pivotal component across various sectors. This versatile product is recognized for its superior surface finish, tight tolerances, and enhanced mechanical properties, making it an ideal choice for applications that demand durability and precision. As industries continue to prioritize efficiency and reliability, understanding the top offerings in this category becomes crucial for manufacturers and decision-makers alike.

This article aims to unveil the top 10 Cold Rolled Carbon Steel Coil products projected to dominate the market by 2025. By exploring the key features, applications, and advantages of each product, we provide valuable insights into how these materials can meet the demands of diverse industries. Whether you are in automotive manufacturing, construction, or appliance production, knowing the best options available can empower you to make informed choices that align with your operational needs and sustainability goals. Together, we will navigate through the cutting-edge advancements that define the future of Cold Rolled Carbon Steel Coil technology.

The cold rolled carbon steel coil market is experiencing a significant upward trajectory, projected to expand from $88.35 billion in 2025 to $134.71 billion by 2032. This growth highlights the increasing importance of cold rolled steel in enhancing manufacturing efficiency across various industries. Companies are continuously seeking ways to optimize their production processes, and utilizing high-quality cold rolled steel coils can substantially contribute to reducing waste and improving overall performance.

Investing in innovative cold rolled products not only helps in meeting the stringent environmental standards set by governments but also aligns with the trend towards sustainable manufacturing. For instance, advancements in production techniques, such as fossil-free milling, are leading to tangible benefits, including a notable 10% reduction in emissions. As the demand for environmentally friendly practices rises, manufacturers who adopt these new technologies can significantly boost their operational efficiency while also fulfilling their corporate social responsibility.

When selecting cold rolled carbon steel coils for your industry, it's essential to understand the key specifications that impact performance and application. Major specifications to consider include the coil thickness, width, yield strength, and surface finish. According to the World Steel Association, the typical thickness range for cold rolled steel coils is between 0.2 mm to 3 mm, with gauges commonly found in applications that require precision and durability. Coil width can vary, but most applications utilize widths ranging from 1000 mm to 2000 mm, which provide versatility for various manufacturing processes.

Tips: Always review the mechanical properties provided by suppliers, especially yield strength and tensile strength. These characteristics directly influence how the coils perform under stress. A noteworthy report by MarketsandMarkets predicts that the global market for cold rolled steel will grow at a CAGR of 4.3%, highlighting the increasing demand for high-strength materials across multiple sectors, including automotive and construction.

Another critical specification is the surface finish, which affects both aesthetics and corrosion resistance. Cold rolled steel typically comes in a variety of finishes, such as matte or polished, which can enhance its resistance to corrosion when properly treated. As indicated by a recent Technical Data Sheet from a leading steel manufacturer, surface treatments like galvanizing can significantly extend the lifespan of the coils in harsh environments. Thus, understanding these specifications will help businesses make informed choices and maximize the utility of cold rolled carbon steel coils.

This bar chart displays the estimated market demand for the top 10 cold rolled carbon steel coil products in 2025, measured in tons. Each product is assessed based on its key specifications including thickness, width, and strength.

Cold rolled carbon steel is increasingly favored across diverse industries due to its exceptional characteristics and versatile applications. One of the primary benefits of using cold rolled carbon steel is its superior surface finish, which provides a smooth and aesthetically pleasing appearance that is critical in industries such as automotive and home appliances. The precise dimensional tolerances achieved through the cold rolling process also make it ideal for manufacturing components that require a high level of accuracy, ensuring better fit and performance in end products.

Additionally, cold rolled carbon steel exhibits enhanced mechanical properties, including increased strength and hardness compared to hot rolled steel. This makes it suitable for applications that demand high resilience, such as structural components, brackets, and frames. Moreover, its ability to be easily formed and welded allows for greater design flexibility and efficiency in production processes. Overall, the benefits of cold rolled carbon steel extend across various sectors, contributing to innovation and quality in manufacturing.

When selecting a cold rolled carbon steel coil supplier, it is crucial to assess several critical factors that can significantly impact your operations. According to the World Steel Association, the demand for cold rolled steel is projected to grow at an annual rate of 3.1% until 2025, highlighting the importance of partnering with a reliable supplier to meet this rising demand. Ensure that your potential supplier has a robust quality management system in place, ideally certified by ISO 9001, to guarantee product consistency and reliability.

Additionally, consider the supplier's range of offerings and technological capabilities. A comprehensive report by MarketsandMarkets indicates that advancements in manufacturing technology are driving down costs while improving quality. Suppliers that invest in state-of-the-art facilities and adhere to stringent industry standards can provide products that meet your specifications almost flawlessly. Engaging with suppliers that offer customization options can also give you a competitive edge, allowing for tailored solutions that align with your unique industry requirements. Gathering feedback from previous customers can provide insights into their reliability and service quality, which are essential for a sustainable partnership.

The modern construction industry is witnessing a transformative shift with the innovative applications of cold rolled carbon steel coils. These products are not only enhancing structural integrity but also optimizing the aesthetic qualities of buildings. The precision and smooth finish offered by cold rolled coils make them ideal for architectural features, giving rise to designs that previously would have been challenging to achieve with traditional materials. Their lightweight nature contributes to efficient construction processes, allowing for the faster assembly of structures without compromising safety standards.

Furthermore, the projected growth of the cold rolled steel market highlights the increasing demand for these materials in various industries. As construction techniques evolve, so does the need for advanced materials that can withstand environmental challenges while offering sustainability. Cold rolled carbon steel coils provide a robust solution that meets these needs, from high-rise skyscrapers to residential buildings. With the global market anticipated to reach approximately $134.71 billion by 2032, the role of these innovative materials in shaping the future of construction is undeniable, offering exciting possibilities for architects and builders alike.